Xylenesulfonic acid entered the chemical industry long ago, finding its roots in the age when coal tar derived aromatics sparked interest across emerging chemical sectors. People in research labs had a persistent drive to derive new sulfonated products from simple aromatic hydrocarbons like xylene, leading to the first syntheses around the turn of the 20th century. It quickly found a purpose in dye manufacturing, as the demand for strong acids capable of improving dye fixation and process efficiency soared. Over decades, this acid traveled from being a specialty chemical to a trusted tool in organic synthesis and commercial applications. In those early years, manufacturing practices relied on crude batch setups and hazardous reagents. Today, modern refinements ensure higher purity, reproducibility, and safety, all result of accumulated practical know-how and advancing regulatory expectations.

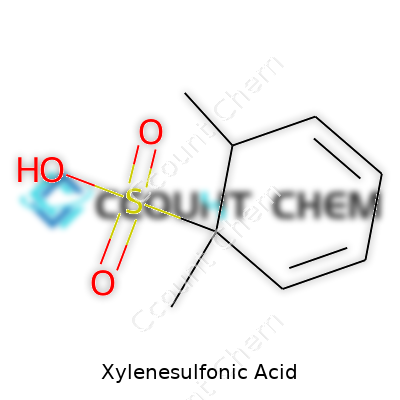

At its core, xylenesulfonic acid arises from the sulfonation of xylene, a familiar aromatic hydrocarbon. The process typically produces a mixture of ortho and para-isomers, with each packing a punch as a sulfonic acid derivative. These compounds appear as colorless to light yellow crystalline solids. Chemists and formulators know this acid offers high solubility in water, maintaining its stability across a range of industrial temperatures. Its strong acidity lends itself to functions traditional mineral acids sometimes struggle with, especially in the presence of organic components. Manufacturers label and sell xylenesulfonic acid in drums or bulk containers that meet the needs of chemical processors, surfactant producers, and pigment industries. Packaging details should always include proper hazard warnings, batch traceability, and handling instructions, reflecting its role as a regulated substance.

Xylenesulfonic acid shows up with a melting point typically near 100°C, though the precise value shifts with the isomeric composition and purity. It dissolves freely in water, and its solutions exhibit potent acidity with a low pKa, sometimes even below 1. Its odor closely resembles aromatic hydrocarbons, and in humid environments, the solid may absorb water, so proper storage remains essential. As a sulfonic acid, it does not readily combust, though xylene residues can present flammability risks under certain circumstances. Chemically, the sulfonic group dominates its reactivity profile, enabling easy salt formation, esterification, and other transformations central to industrial chemistry. Some users prefer its predictable stability over alternatives like benzene sulfonic acid, especially in formulations that experience pH and temperature fluctuations.

Manufacturers base technical specifications on purity, isomeric distribution, moisture content, and byproduct levels. Purity typically exceeds 95%, with some specialty markets demanding even tighter standards. Modern labeling draws on globally harmonized system criteria, outlining signal words such as “Danger,” specific hazard pictograms, and detailed response advice for exposure or spills. Certifications often accompany each batch, confirming compliance with local or international chemical control statutes. These technical details ensure users get material that fits their process needs, whether for organic synthesis, catalyst preparation, or surfactant manufacture.

Preparation hinges on sulfonation of xylene isomers using concentrated sulfuric acid or oleum. Operators maintain control over temperature and reagent ratios to direct sulfonation toward the desired ortho or para isomer, and downstream processing separates the isomeric mixture if needed. After neutralization and purification, plant operators recover the sulfonic acid by crystallization or solvent extraction. Modern plants aim to minimize acid fumes and residual sulfur contaminants, so closed-system reactors, proper scrubbing technology, and careful pressure control play major roles. Efficient handling of waste acid streams, solvent recovery, and energy use drives both economics and environmental compliance at this stage.

One of the main attractions of xylenesulfonic acid lies in its versatility as a chemical building block. The sulfonic group undergoes straightforward neutralization with alkali bases, yielding stable sulfonate salts useful as surfactants or water softeners. Chemists often transform these acids into sulfonate esters, which function as intermediates in dye, pigment, and pharmaceutical pathways. The aromatic backbone also permits further electrophilic substitution, expanding opportunities for custom tailoring. In some synthesis routes, the presence of the sulfonic group helps activate other aromatic positions, pushing reactivity deeper than in non-sulfonated aromatics. These features give formulators a broad canvas for crafting next-generation polymers, dyes, and detergents.

Depending on supplier or formulation need, xylenesulfonic acid may show up under various synonyms. Classic chemical references list it as xylene sulfonic acid, methylbenzenesulfonic acid, or sometimes under the separate titles of ortho-xylenesulfonic acid and para-xylenesulfonic acid. Product names might carry company branding, but the core identity rests on the three-methyl structure with the sulfonic acid group bonded to the aromatic ring. Keeping these synonyms straight remains central for safety documentation, regulatory records, and technical troubleshooting. Failure to recognize alternate names can lead to confusion in communication or procurement activities.

Standard chemical handling rules apply here, but given the substance’s strong acidity, operators need proper PPE, including gloves and eye protection during transfer or sampling. Ventilated areas cut down on inhalation risk and accidental contact. Safety data sheets provided by suppliers outline first aid responses, best practices for spills, and storage guidelines. Regulations in many countries limit workplace exposure, and plant managers audit operating procedures to reflect the latest knowledge in chemical hygiene. Workers receive regular training, and facilities maintain ready access to neutralizing agents and wash stations. These measures protect not just personnel, but also downstream communities and the environment by reducing the risk of accidental release or improper waste treatment.

Xylenesulfonic acid crops up in several industries. The detergent sector values its contribution as a starting point for surfactant generation, where its salts play a role in everything from liquid laundry products to industrial cleaning agents. The dye and pigment industries have long exploited its reactivity to enhance dye application, improve solubility, and fix color chemically to textile substrates. Some specialty resin producers use it as a curing catalyst or to modify polymer backbone properties. Water treatment facilities sometimes use its salts to address calcium scaling and improve plant throughput. Custom synthesis shops and pharmaceutical developers reach for the acid during steps demanding high proton activity and aromatic group modification.

Aggregate research around xylenesulfonic acid moves in two primary streams. Industrial chemists chase methods that increase selectivity and reduce process waste during sulfonation and isolation. Advanced catalyst systems, recycling methods, and physical process intensification (like continuous flow reactors) all form part of this pursuit. Meanwhile, academic groups dig into its fundamental reactivity, exploring new cross-coupling routes, functional group exchanges, and even bio-based conversion strategies. There’s growing interest in minimizing the environmental impact by designing greener synthesis workflows and exploring alternative sulfonating agents. Ongoing collaboration between industry and university labs keeps the knowledge base fresh and responsive in the face of tightening global regulations.

Toxicity research draws both on animal studies and workplace exposure data. Acute exposures at high concentrations trigger skin and eye irritation, so plant operators remain vigilant with corrective gear and proper containment. Chronic exposure research remains limited, but so far, most data indicate low systemic toxicity if safety protocols function as intended. Environmental research tracks breakdown products and persistence, with findings supporting moderate aquatic toxicity, especially for downstream sulfonate salts. Wastewater treatment routines focus on breaking down sulfonic acid residues, and regulators insist on detailed effluent monitoring. Ongoing studies keep risk assessments grounded, updating operating parameters as new findings emerge.

Shifting environmental demands and changing economic forces push manufacturers and downstream users to look for new efficiencies and greener methods. The movement toward safer, less wasteful sulfonation has broad industry support, showing promise with continuous manufacturing and less hazardous reagent use. Growth in emerging markets, especially where water treatment and urban development expand, will likely keep demand steady for sulfonated intermediates. Surfactants, detergents, and improved polymer modifiers drive steady innovation, with process engineers continuously fine-tuning reaction conditions to balance purity, cost, and sustainability. New academic research, including bio-based routes and novel catalytic transformations, suggests that xylenesulfonic acid and its derivatives will continue to occupy a useful spot in chemical manufacturing, provided producers keep pace with environmental and safety norms.

Xylenesulfonic acid often pops up in the world of industrial chemistry. With a structure built around xylene and a sulfonic acid group, it brings strong acidic properties to the table. This strength gives it a role in several manufacturing processes, especially where faster or more controlled chemical reactions matter. If you walk through a facility making specialty chemicals or polymers, this compound likely has a spot somewhere along the production line.

Cleaning products stay influential in society’s drive for better hygiene. The chemical industry relies on xylenesulfonic acid as a surfactant or an additive for liquid detergents. It keeps formulas consistent and helps water mix with oils and grime, breaking up stains more easily. Surfactant blends often perform better when this acid is part of the recipe, and everyday washing gets a boost.

The textile and dye sectors also turn to xylenesulfonic acid for help. It acts as an intermediate in synthesizing organic dyes and pigments. Dye makers get cleaner, more vibrant colors because this compound promotes stronger bonds and better dispersion through solutions. T-shirts, upholstery, even coloring for plastics—many shades trace their intensity and evenness back to this acid’s performance behind the scenes.

Catalysts shape the plastics found everywhere, and xylenesulfonic acid meets this need in various polymerization reactions. Its role as a catalyst can speed up the reaction, sidestep unwanted byproducts, and lower the cost of high-value materials. In real-life applications, certain types of resins, adhesives, and coatings owe their properties to this compound’s ability to boost yield and efficiency. Anyone working with epoxy or phenolic resins probably recognizes its value.

Heavy industries often leave tough stains and residues that typical cleaning agents can’t touch. Xylenesulfonic acid makes industrial cleaning solutions that much stronger. Its acidity breaks down stubborn residues on metal, plastic, and even concrete. Plants that clean manufacturing equipment or restore contaminated surfaces see savings in time and labor when this acid gets blended in.

Handling harsh acids always brings a degree of risk. Breathing fumes or direct contact with xylenesulfonic acid can lead to skin, eye, or respiratory irritation. Workers must wear strong gloves, goggles, and use ventilation systems. From my own time on chemical plant floors, trainings and safety briefings always gave xylenesulfonic acid special attention.

Concerns stretch beyond the lab. As with many sulfonic acids, improper disposal spills into local water or soil, damaging ecosystems. Responsible companies enforce containment and neutralization protocols to keep the wider environment out of harm’s way. Routine audits and working with reputable suppliers cut down on accidental releases.

Switching from bulk handling to premeasured, sealed containers keeps exposure risk low. Installing real-time leak detectors in storage or mixing areas limits large spills. Some companies also invest in acid-resistant piping and secondary containment tanks to add redundancy. My colleagues and I often debated the best gear for safe transfers, and consensus always favored features that stopped spills before they started.

From keeping cleaning products effective, to building sturdy plastics, to supporting cleaner water, xylenesulfonic acid underpins many everyday conveniences. When chemistry moves into the real world, balancing power and safety matters more than ever.

People who spend time around chemical industries or labs quickly realize that formulas like C8H10SO3 aren’t just numbers and letters. Xylenesulfonic acid, as the name hints, starts with xylene—an aromatic hydrocarbon with a benzene ring and two methyl groups. Jumping into sulfonation, a sulfonic acid group (SO3H) attaches to that xylene backbone. This converts something flammable and sweet-smelling into a strong acid used for manufacturing dyes, surfactants, and specialty chemicals.

People toss around chemical names and formulas, but this one makes a mark. Laboratories often use xylenesulfonic acid for its ability to adjust pH, drive reactions faster, and help carry out processes cleanly. Accuracy matters here, not just for a homework answer, but because reactions change if you get this formula wrong.

Years back, during a stint at a water treatment plant, I saw the wrong sulfonic acid delivered—close formula, different reactivity. The pH went off the rails and cost hours to recalibrate. It’s not about just mixing chemicals; small errors in identifying compounds cost time, money, and sometimes safety.

Look beyond the lab. Many everyday items pass through chemical tweaks that count on molecules like xylenesulfonic acid. Start with dyes in clothing—these mixtures need acids to bind color, keep it from washing out, and maintain brightness. Cleaning products and detergents also draw from this type of chemistry. The molecules help break up grease and dirt, making cleanup quicker and more thorough.

If you enjoy smooth-flowing paints or advanced plastics, there’s a chance this acid played a role earlier on in their production. Behind the curtain of brands and advertising, safe and effective products hinge on the reliability of these core ingredients.

Chemicals with strong acids, like xylenesulfonic acid, don’t mix well with carelessness. Even with the best formulas, misuse can burn skin and damage surfaces or lungs. Factories and labs treat such substances with protocols—goggles, gloves, careful labeling. Accidents most often trace back to rushed work or inattention, not the chemicals themselves.

My time training new plant workers taught me that learning the formula isn’t just a test-box to tick; it’s about knowing what you’re working with. Whether it’s understanding neutralization points or calculating dosage, the specific arrangement of carbon, hydrogen, sulfur, and oxygen atoms—C8H10SO3—is where safety starts.

Making industries safer and more efficient means better training and clearer labels. Chemical suppliers and safety organizations should keep publishing new data sheets, easy-to-understand guides, and updated emergency steps. Even veteran staff can forget procedures after years on auto-pilot. On-site refresher courses, accessible emergency equipment, and regular review of inventory make a difference.

Trust in chemical production builds on everyone down the line knowing what C8H10SO3 stands for, what it does, and how to handle it. That trust keeps the supply chain reliable and the end products safe for the people who eventually use them.

Xylenesulfonic acid can be a harsh chemical. Anyone who’s worked with strong acids in a lab or industrial setting remembers the first lesson: respect the substance. I learned this lesson early on—just a few drops on exposed skin can cause irritation. Eyes feel the burn even faster. The reason for this is the acidity. Xylenesulfonic acid, like many sulfonic acids, reacts quickly with tissues and can lead to lasting damage if not rinsed away right away.

Inhaling the fumes is no light matter either. Even brief exposure can cause coughing or, after longer periods, more serious breathing difficulties. Long-term exposure might do more damage, especially for anyone with respiratory issues. Splashes to the eyes or skin need rinsing without hesitation. It’s easy to underestimate the risk, especially during routine jobs, but becoming complacent invites trouble. The eyes remain especially vulnerable, taking only one small mistake to change a career—or a life.

Anyone handling this acid should wear chemical splash goggles. Regular glasses don’t provide the seal needed. I always reach for nitrile gloves, which handle acids better than most alternatives. Thick rubber gloves offer extra peace of mind during cleanups. A good lab coat or chemical-resistant apron helps protect the body from accidental splatters.

Face shields step in for bigger jobs or when pouring larger volumes. Closed-toe shoes guard the feet. Adequate ventilation isn’t a fancy recommendation—it’s a necessity. I remember a time ventilation fans failed in a work area, and you could smell the acrid vapor within minutes. In poorly ventilated spaces, fumes build up and linger, leading to headaches and nausea swiftly.

Store this acid in tightly sealed containers, away from sunlight and moisture. The best practice is to keep it separate from strong bases or substances it might react with. Label everything clearly—nobody wants a mix-up, especially where strong chemicals are involved. I’ve seen too many close calls caused by rush jobs or sloppy storage habits. Frequent checks on containers help catch leaks or damaged seals before they become a problem.

Accidents happen—even to careful workers. Keep neutralizing agents like sodium bicarbonate nearby, along with absorbent pads. Never clean up a spill with bare hands. Even small releases can become big headaches if someone tries to mop up with the wrong gear or doesn’t ventilate the area. Alert colleagues right away during a spill. Quick action can prevent long-term issues.

Pouring acids down the drain might seem easier, but it’s dangerous for workers and the environment. Always use approved hazardous waste containers and check the local rules. Many cities offer specific guidelines, and following them keeps everyone safer. Each step, from transfer to final disposal, deserves the same level of attention as the actual handling.

I always remind new team members that safety isn’t a one-time lesson. Refresher courses offer new insights, often informed by prior mistakes or near-misses. The chemically aware stay that way through steady practice and updated know-how—not by luck. Knowledge, careful habits, and the right equipment form the best defense against hazards in the workplace.

I’ve worked around chemicals long enough to spot the difference between a minor spill and a dangerous mess. Xylenesulfonic acid brings a swooping punch to the mix when it slips out of safe hands—it’s corrosive, reacts aggressively with water, and finds its way into trouble if left unchecked. The stakes rise in commercial settings, with tanks, pipes, and containers all facing long-term exposure.

Deciding where and how to store something so reactive didn’t start with internet advice. Years ago, I watched a colleague struggle with warped containers and half-melted labels in a hastily chosen corner. We learned fast. Safety comes from picking containers that never flinch at the touch of acids—polyethylene and glass stand up, while metals often give up and corrode. Using steel in direct contact with a strong acid led to rust, pitting, and the sort of leaks that cause late-night phone calls.

I always read a chemical’s safety data sheet before it ever shows up in a drum or bottle. The section on storage tells its own story. With xylenesulfonic acid, air-tight lids become the only reasonable option, not just for worker health, but for long-term product life. Moisture wrecks this acid over time, so rooms lined with dehumidifiers and dedicated shelving cut down on risk.

The thing with strong acids is—they drift where they want if left unchecked. I’ve walked into storage rooms that felt like humid greenhouses, and every label in sight had turned to a blur. Even a little moisture, creeping in from a poorly sealed window, can nudge xylenesulfonic acid into a reaction nobody wants to clean up. Solid floors—sealed concrete or acid-resistant tiles—save a lot of regret. The goal always: keep leaks from reaching drains or seeping into the building’s joints.

One autumn, after a shipment arrived on a muggy day, a friend of mine went to check on the stock. Rust bloomed under one drum. They caught it quick, swapped out the drum, aired out the room, and started keeping a cheap but effective humidity gauge on the door. These adjustments only came after close calls; nobody should wait for this kind of wake-up.

Gloves, splash goggles, and aprons form the basic wardrobe near this acid. Keeping extinguishers and emergency eye-wash stations close is not pointless ritual—acid burns don’t pause for confusion. Training new team members takes extra time, but every hour spent means fewer rushed mistakes. Knowing the difference between a quick cleanup and an emergency shapes a crew’s confidence.

Real Solutions for Real SettingsClear labeling stands out, not for bureaucracy’s sake, but because knowing what sits inside a drum makes every step easier, especially during emergencies. Good storage isn’t about expensive gear, but keen habits—dry rooms, the right drums, prompt spill control, routine checks. Relying on plain experience and facts saves money, protects health, and keeps everything a lot more predictable. That’s not theory; it’s what keeps shops, labs, and storage rooms from showing up in tomorrow’s headlines.

Think about tossing a spoonful of salt in a glass of water. Salt vanishes, and the taste tells the truth about its solubility. Now, place xylenesulfonic acid in that glass. This acid comes from the xylene family, a group of chemicals people find in paint thinners and fuel. Chemists tag xylenesulfonic acid not just for its roots in the lab, but because it dissolves remarkably well in water. The reason isn’t magic. Its structure packs a strong sulfonic acid group that grabs onto water molecules, splitting up easily and blending in.

There’s more at stake than chemistry trivia. Xylenesulfonic acid’s strong solubility means it slips straight through water treatment plants, heading downstream into rivers and lakes if not watched closely. This raises flags for people worried about water quality and downstream effects. Plenty of industrial cleansers and specialty detergents pick xylenesulfonic acid for its cleaning power, thanks in large part to the way it mingles so smoothly in water. This also means any spill or disposal becomes a public health question, not just a technical one.

Ease of mixing also spells responsibility. Picture large-scale facilities that toss tons of chemical-based cleaners into their daily routine. A solution that dissolves as easily as xylenesulfonic acid can surprise operators if they haven’t set up the right safety barriers and monitoring systems. From my experience talking with professionals in the water utility sector, chemists and plant managers trade lessons on how to measure and neutralize specialty acids before water cycles back into public use. Reports published by organizations like the Environmental Protection Agency warn that untreated sulfonic acids slip right through many standard water filters, partly because their high solubility makes traditional chemical removal less effective.

Responsibility falls on both industry and lawmakers. Facilities can invest in systems that neutralize or recover chemicals like xylenesulfonic acid before they enter waste streams. Technologies such as advanced oxidation or activated carbon filtration capture more than basic filters ever could. On top of that, tighter rules on chemical discharge and regular site inspections cut the odds of accidental release. From what I’ve seen in regulatory guidance, tracking chemical movement through digital logs and transparent reporting allows both companies and environmental agencies to catch problems early. That’s not just good policy — it helps keep people’s tap water safer.

Soluble chemicals present real challenges, but they also nudge industries toward smarter habits. Adopting safer alternatives, cutting down unnecessary use, updating spill response plans, and listening to public health advocates all steer the conversation in the right direction. Xylenesulfonic acid isn’t just a chemistry lesson. Its story offers a window into balancing promise and risk in everyday manufacturing. As new research turns up better ways to clean, treat, or swap out these chemicals, keeping a close watch on their journey through water remains key for everyone’s well-being.

| Names | |

| Preferred IUPAC name | benzenesulfonic acid |

| Other names |

Benzenesulfonic acid, methyl- Methylbenzenesulfonic acid Xylene sulfonic acid Dimethylbenzenesulfonic acid |

| Pronunciation | /zaɪˌliːn.sʌlˈfɒn.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 1300-82-1 |

| Beilstein Reference | 1718739 |

| ChEBI | CHEBI:38230 |

| ChEMBL | CHEMBL46423 |

| ChemSpider | 22134286 |

| DrugBank | DB11339 |

| ECHA InfoCard | ECHA InfoCard: 100.009.844 |

| EC Number | 215-321-3 |

| Gmelin Reference | 7843 |

| KEGG | C06117 |

| MeSH | D014983 |

| PubChem CID | 70468 |

| RTECS number | ZE5425000 |

| UNII | R1T7O2S2DF |

| UN number | 2586 |

| CompTox Dashboard (EPA) | DTXSID5021816 |

| Properties | |

| Chemical formula | C8H10O3S |

| Molar mass | 172.20 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | strong aromatic odor |

| Density | 1.18 g/cm3 |

| Solubility in water | Soluble in water |

| log P | -1.3 |

| Vapor pressure | 0.93 hPa (20°C) |

| Acidity (pKa) | -2.5 |

| Basicity (pKb) | -6.5 |

| Magnetic susceptibility (χ) | -51.5e-6 cm³/mol |

| Refractive index (nD) | 1.515 |

| Viscosity | 25 cP (25°C) |

| Dipole moment | 2.95 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 203.0 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | -509.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3724.3 kJ/mol |

| Hazards | |

| Main hazards | Corrosive, causes severe skin burns and eye damage, harmful if swallowed, harmful if inhaled |

| GHS labelling | **"GHS05, GHS07"** |

| Pictograms | GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H314: Causes severe skin burns and eye damage. |

| Precautionary statements | P264, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 3-0-2-A |

| Flash point | 102°C |

| Autoignition temperature | 450 °C |

| Lethal dose or concentration | LD50 Rat oral 1,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 1200 mg/kg |

| PEL (Permissible) | 50 ppm |

| REL (Recommended) | 0.2 mg/m³ |

| IDLH (Immediate danger) | IDLH: 80 ppm |

| Related compounds | |

| Related compounds |

Benzenesulfonic acid Toluenesulfonic acid Cumene sulfonic acid Xylene Sulfanilic acid |