Strong acids hold a strange fascination for both chemists and manufacturers, and toluenesulfonic acid, as a proud member of the sulfonic acid family, tells a story shaped by necessity and innovation. The chemical industry started paying close attention to aromatic sulfonic acids in the late nineteenth century. The growing demand for dyes, pharmaceuticals, and detergents drove early chemists to seek out acids that combined high solubility with strong acidity. The introduction of toluenesulfonic acid, particularly the para-isomer (p-TsOH), represented a leap forward. This compound carved out its own niche: less fuming and easier to handle than sulfuric acid, but still packing the acidic strength needed to get serious work done on the lab bench and production floor. Over time, chemists figured out how to make it in large quantities, tweak its purity, and adapt it for dozens of industries. Its rise follows the general pattern of chemical adoption—proof of utility followed by consistent demand and, eventually, integration into production pipelines worldwide.

Tosic acid—as those who work with it often call it—shows up as a white crystalline solid that people use wherever they want strong, non-oxidizing acidity. This acid plays especially well in organic chemistry, including synthesis, catalysis, and certain purification steps. It replaces mineral acids when oxidation can create headaches. Commercial grades come as powders, granules, or sometimes wet cakes. Anyone buying p-TsOH expects purity above 98%, often as high as 99.5%, with suppliers pushing toward even finer grades for electronics and pharmaceuticals. While it's not a household name outside laboratories, the chemical operates quietly across multiple sectors, shaping end products most consumers never think about.

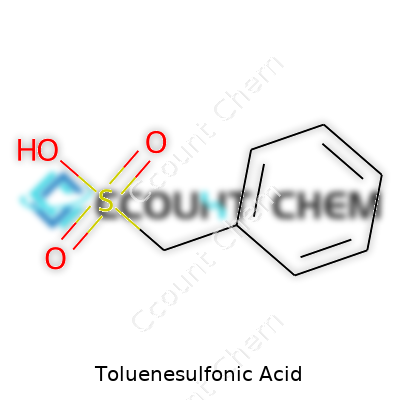

In day-to-day work, it matters that toluenesulfonic acid dissolves easily in water, alcohol, and many organic solvents, but stays stubbornly solid at room temperature. Its melting point hovers around 106–107°C. The acid dissociates almost completely in water, unleashing a strong acid punch. Chemists love that it adds acidity without unwanted water or the harsh fumes of hydrochloric or sulfuric acid. On the chemical side, p-TsOH comes with a benzene ring attached to a sulfonic acid group and a methyl group for good measure. That structure makes it more flexible in organic transformations, especially as a catalyst in processes from esterification to the cracking of polymers.

Technical documentation spells out expected features—from melting point and assay by titration, to water content by Karl Fischer, and limits on heavy metals and inorganic salts. Good labels include warnings for corrosivity and recommendations for protective gear. Most drums and bags carry the correct UN number for hazardous materials and the product’s synonyms, so cross-referencing in global trade stays straightforward. In tighter regulatory markets, technical files also show batch data, GMP status for pharmaceutical or food applications, and trace metals data.

Manufacturers turn out p-toluenesulfonic acid using sulfonation of toluene, usually with sulfuric acid or oleum, sometimes with a bit of catalytic help. The resulting mixture cools, then undergoes neutralization before isolation as the acid or conversion to salts like sodium p-toluenesulfonate. Companies focus on getting high yield and high purity, since trace oxidizers or residual sulfuric acid can spoil reactions downstream. Modern plants run continuous processes for consistency, often recycling waste streams and capturing volatile by-products for cleaner production.

The chemistry books cover plenty of reactions using p-TsOH. It acts as a solid acid catalyst in Friedel–Crafts acylation, esterification, ether formation, hydrolysis, and polymerization. One trick organic chemists like: using p-TsOH to deprotect acetals under mild conditions—much gentler than hydrochloric acid. Another common move: convert the acid into p-toluenesulfonyl chloride and use that as a leaving group for sulfonation or protection chemistry. Across multiple labs, p-TsOH remains a favorite for peptide coupling, driven by its ease of use and ability to leave behind only a non-volatile salt. People also tweak its reactivity by preparing various salts, which adjust solubility and reactivity for water or organic reactions.

Anyone doing business across borders knows that p-toluenesulfonic acid has a handful of aliases: TsOH, tosic acid, p-TsOH, 4-methylbenzenesulfonic acid, and 4-toluenesulfonic acid. Commercial labels sometimes use “tosylic acid.” Salts carry names like toluenesulfonate or tosylate. In bulk chemical catalogs, suppliers often shorten it right down to “p-Toluenesulfonic Acid Monohydrate” if it holds crystallization water.

Safety matters with any strong acid. p-TsOH ranks as corrosive, causing burns on skin and eyes and releasing fumes that can damage the lungs if inhaled. Anyone handling it in labs or warehouses wears gloves, goggles, long sleeves, and uses fume hoods or local ventilation. Disposal protocols send spent material through neutralization with alkali or lime, not straight into the sewer. Companies shipping p-TsOH comply with local and international regulations for transport, labeling, and emergency response. Training materials highlight first aid—plenty of water for skin splashes, and quick medical attention for eye or respiratory exposure. Production facilities monitor air quality and often automate bagging or drum loading to reduce direct handling.

p-TsOH finds plenty of work in the world outside pure chemistry. The pharma industry uses it as a catalyst in drug synthesis and for making tosylate drug salts—many antihistamines and antibiotics arrive as tosylates to improve their solubility or stability. In resins and plastics, p-TsOH kickstarts polymerization, ensuring crisp curing in epoxy and phenolic products. Textile processors favor it for dyeing and finishing, where acid stability matters under high temperature and open air. Oil refineries employ it in refining steps that demand high acidity without the risk of water contamination. Food tech sometimes makes limited use of toluenesulfonic acid, but regulations keep it out of most direct-contact processes. Laboratories prize p-TsOH for everyday synthesis, especially for work needing strong but controllable acid—a reliable friend for making esters, ethers, and deprotection reactions that can’t tolerate strong oxidizing agents.

Research into new uses for toluenesulfonic acid marches on. Scientists test modified acid salts for performance in green catalysis, aiming to replace mineral acids with safer, more recoverable alternatives. Some groups develop supported p-TsOH on polymers or silica for easier separation and repeat use. The search for new pharmaceuticals drives chemists to experiment with tosylates for improving water-solubility and absorption rates in the body. Digital modeling now boosts understanding of how p-TsOH catalyzes different transformations, letting teams tweak conditions for lower waste and higher yield. Even in undergraduate chemistry, p-TsOH keeps showing up in textbooks and teaching labs as a reliable benchmark for acid strength and ease of handling.

Toxicity data show p-toluenesulfonic acid poses a hazard through direct exposure. Acute contact with skin burns within seconds, and inhaling dust can bring severe irritation to the lungs and throat. Chronic exposure stays rare in regulated environments, but animal studies show that high doses damage liver and kidney tissue in test animals. Fortunately, most production plants and labs control airborne dust and require personal protection, so large-scale incidents remain limited. No reports link p-TsOH to carcinogenicity or reproductive toxicity. Environmental release breaks the acid down slowly, but dilution and neutralization bring risk under control. Wastewater treatment plants can process neutralized toluenesulfonate salts, though dedicated scrubbers and neutralization tanks help larger sites stay on the right side of environmental limits.

The future of toluenesulfonic acid looks stable and adaptable. Green chemistry efforts push companies to recycle spent acid, isolate by-products, and reduce reliance on mineral acids in bulk processes. Growing electronics manufacturing demands ever-purer acid catalysts, opening new ground for ultra-refined grades and certifications. With more pharmaceuticals turning to tosylate salt forms, chemical firms keep refining production to meet tighter standards: lower metals, lower residual solvent, and batch traceability. Research keeps widening the use of toluenesulfonic acid in new polymer chemistry and specialty coatings. Digital plant control lets bulk manufacturers run cleaner, safer, and at higher yield than the toluene-sulfonation setups of the past. With more regulations and watchdogs, the companies that thrive will be those embracing transparency, safety, and digital traceability from the warehouse to the reactor. Over the coming decade, the role of p-TsOH may not grab headlines, but day after day, it will keep shaping products and processes around the world, quietly laying down strong acid power where precision and performance matter.

Toluenesulfonic acid finds its way into so many corners of daily life and modern industry that I rarely come across a chemistry lab or manufacturing facility that doesn’t keep a drum of it on hand. With a reputation as a hard-working acid, this compound takes center stage in both heavy industry and delicate pharmaceuticals. I remember the first time I worked with it in a small research lab—the label jumped at me because it meant business.

Many chemists reach for toluenesulfonic acid because it delivers strong, reliable acidity. Its use as a catalyst shines most in reactions where water as a byproduct gets in the way. For example, in esterification—making esters from acids and alcohols—this acid pulls the water out so the reaction charges forward. I’ve seen it speed up sluggish processes that would otherwise drag on for days.

In organic synthesis, its main appeal comes from stability in both solid and solution form. This improves safety and handling compared to stronger mineral acids like sulfuric acid. When making pharmaceuticals, toluenesulfonic acid helps chemists transform basic chemicals into something that can save lives. It plays a part in forming salt versions of drugs, which can improve how they dissolve and work in the body.

On the industrial side, toluenesulfonic acid gets involved in making adhesives, resins, and even dyes. Its strong acidity kicks polymerization into gear, which helps plastics and coatings come together faster and more reliably. I’ve seen manufacturing operations switch to this acid because its efficiency can outpace older, clunkier catalysts.

In electronics, especially in making circuit boards, it helps clean and prep metal surfaces without causing the mess or harshness of more aggressive acids. This matters because a good, clean copper layer means fewer problems down the line.

Of course, strong acids bring their own set of challenges. Toluenesulfonic acid can burn skin and eyes; I never forget gloves and goggles after one careless splash stung for days. Its effects on the environment raise questions, as run-off into water can harm plants and animals. Facilities need solid safety plans and disposal routines to keep people and ecosystems out of harm’s way.

It comes down to a balance. Strong acids like this speed up the world around us, but not without risk. Innovation around safer packaging, spill kits, and emergency education make a difference. Some groups look for milder options or more efficient methods so factories don’t have to rely on harsh ingredients as much. Green chemistry, with its push for less-toxic chemicals, encourages creative minds to design new catalysts that get the job done with less harm.

Toluenesulfonic acid won’t vanish overnight from labs or assembly lines. Its value remains in making bold transformations, whether that’s crafting plastics, pharmaceuticals, or specialty chemicals. Smarter handling, more robust safety practices, and continued research into alternatives can keep the benefits while shrinking the downsides. Chemical work is always a balancing act—choosing the right tool at the right time, and respecting every drop that comes out of the bottle.

Plenty of folks who work with chemicals every day know that handling certain substances can bring surprises. Toluenesulfonic acid has a reputation in chemistry circles. It’s often used as a catalyst in organic and industrial work. Every time this compound makes its way onto a workbench, someone in the room remembers the hazard signs. And for good reason.

Here’s the thing about toluenesulfonic acid—its strength gets all the attention. It’s a sulfonic acid, which means tissue won’t react kindly to it. A single drop landing on your skin will start burning right away. Eyes feel the sting even quicker. Fumes from the dry powder can drift into the nose and mouth, triggering coughing. Heavy exposure can irritate the respiratory tract. Not only that, but if someone handles it without gloves, the skin dries out, cracks, and may not heal up for weeks. People who don’t wear goggles risk their eyes, and plenty have rushed to eyewash stations after splashes.

Back in my early days in the lab, someone dropped a scoop of the powder onto a bench. The white dust spread and set off a round of sneezing and coughing. Most of us learned quickly to clean up the mess with plenty of water, never dry sweeping. That kind of situation sticks with you. Workers who spend years around strong acids like this keep barrier cream handy, double-check that gloves aren’t wearing thin, and make sure lab coats are buttoned up.

Nobody looks forward to chemical burns or breathing trouble. It’s not just discomfort; long-term contact raises risks for health issues. Prolonged exposure can trigger asthma-like symptoms or lead to chronic skin problems. A few moments of carelessness leads to big problems later. Nothing boosts awareness like seeing a colleague struggle with painful burns after a splash.

Effective handling doesn’t need to feel like walking on eggshells. The basics make all the difference. Eye protection, acid-resistant gloves, and a solid lab coat. Work in well-ventilated rooms or keep a fume hood running. Dry acid needs extra attention; it dusts off surfaces easily. Wet towels or disposable pads pick up more safely after a spill. Always have neutralizing solutions—like sodium bicarbonate—on hand, so spills don’t linger. Train newcomers often. Accidents drop when the team shares their war stories and advice. Older workers show up new arrivals that short sleeves and open shoes don’t cut it. Treat cleanup seriously, and everyone leaves in one piece.

Not every workplace can install fancy exhaust systems, but even small businesses can rely on some basics. Keep safety data sheets where everyone can reach them. Stock up on the right kind of gloves and switch them out often. Encourage a culture where no one gets mocked for asking if they’re protected well enough. Encourage reporting near-misses, so the next worker learns from mistakes that almost led to trouble. Track inventory and never store strong acids with incompatible chemicals, like bases or oxidizers. Emergency showers and eyewash stations near the work area give peace of mind and real protection if something goes wrong.

Working with toluenesulfonic acid isn’t something to fear, but it deserves respect. Trust in training, good habits, and safe tools. In the end, hands, eyes, and lungs all last longer.

If you’ve ever spent time around a laboratory or browsed the label of a specialty cleaner, toluenesulfonic acid probably looks familiar. Its chemical formula, C7H8SO3, describes a molecule made of carbon, hydrogen, sulfur, and oxygen. This set-up comes from a toluene ring—a pretty basic shape in organic chemistry—clipped with a sulfonic acid group. Toluene gives the backbone, and the sulfonic acid brings in the extra reactivity.

In practice, toluenesulfonic acid offers more than a mouthful of syllables. Organic chemists keep it close for a reason: the compound knocks out water from many reactions and can nudge slow molecules along when others pause. It has a punchy acidity, but it is less harsh on glassware or human hands compared to some mineral acids. In my post-undergrad days, I learned to respect how it sped up reactions without the headaches that strong mineral acids often brought. Spilled sulfuric acid etched glass, but toluenesulfonic acid let us focus on the experiment, not the cleanup.

This formula, C7H8SO3, tells more than what sits in the beaker. Production cycles for adhesives, dyes, pharmaceuticals, and even certain plastics depend on molecules with specific compositions. Any changes to an active ingredient’s formula can spell real consequences—good or bad—for those downstream. Knowing exactly what we are working with cuts out surprises, whether in an industrial batch or in small-scale research. I’ve watched entire processes go sideways because the purity or structure of a chemical didn’t check out. Developing a strong sense around composition—like knowing toluenesulfonic acid inside and out—lets chemists and engineers sidestep trouble before it begins.

Toluenesulfonic acid shares some pros and cons common to many strong acids but with less volatility. As with nearly any acidic chemical, skin contact can burn, and inhaling dust feels harsh. The broader significance comes in waste disposal and worker safety. Even low-toxicity acids can pile up in waterways if industrial users cut corners. Strict chemical handling procedures reduce accidents and keep the chemical’s risks manageable.

Much of the risk from toluenesulfonic acid, I’ve found, rests not in the molecule itself but in attitudes about handling and disposal. Many accidents come from ignoring small leaks or assuming someone else will clean up. Regular refresher training, labeling everything, and investing in containment gear make a massive difference. Improving supply chain transparency on purity and origin would help cut down on product recalls and improve final product reliability in sensitive uses like electronics or pharma. Small changes—like switching to reusable or recyclable containers—do a lot for sustainability without adding much to overhead.

Advances in green chemistry and waste reclamation could push industries to use toluenesulfonic acid in cleaner cycles, reclaiming or neutralizing spent acid rather than releasing it. The chemical formula doesn’t change, but how we use and recycle it will define whether the acid remains a reliable asset or drifts into environmental trouble. Science has plenty of road left to run in making strong acids safer, cheaper, and easier on our world.

Even after all these years of dealing with chemicals in different labs and small manufacturing plants, one thing stands out: careless storage brings trouble. It’s not about fancy protocols. It’s about safety, keeping your investment intact, and not waking up to an emergency call. Toluenesulfonic acid, whether as a white crystalline solid or a liquid solution, fits this story well—treated the wrong way, it causes corrosion, releases fumes, or reacts with water. Once you’ve cleaned up a spill in an old storeroom, you learn to take precautions seriously.

Years ago, I saw a shipment left in the sun near a loading dock, triple-wrapped but sweating in humidity. Next morning, the outer drum looked as though it had survived a rainstorm, stripes of corrosion showing up fast. That’s not rare. It’s easy to let little details slide, especially on a busy day. Most folks know to keep acids away from bases and strong oxidizers. But I’ve seen Toluenesulfonic acid stored on wooden shelving already rotting from moisture. Wood isn’t neutral—acid will eat through it, risking slow leaks and damage.

Stainless steel and high-density polyethylene containers handle Toluenesulfonic acid best. Glass works for small amounts, but once you hit industrial scales, sturdy drums are the only real option. Over the years, every good stock manager checks barrels for nicks, cracks, or warping. Genuine long-term storage jobs always include secondary containment—simple trays, spill pallets, and liners. An accidental crack doesn’t become a disaster with these in place.

Dry, cool rooms with steady ventilation keep fumes low and objects stable. Excess heat speeds up decomposition and shifts in concentration—both problems for anyone who cares about product quality. I tend to favor rooms with temperature monitoring, not just a simple thermometer stuck to a wall. Reliable sensors mean you catch problems early, preventing squabbles between suppliers and buyers over questionable shipments.

Clear labeling matters. You’d be surprised how many times new staff, or even old hands in a hurry, confuse containers. Consistent, readable tags cut out guesswork. Each barrel or bottle should show not only the product name but hazard pictograms, dates, and the person responsible for that batch. At a midsize chemical plant, the labeling system paid off after a power outage. Amid the chaos, workers didn’t waste time sorting through containers—the system prevented a messy mix-up.

Keeping the wrong people from wandering through chemical storage is just common sense. Locked doors, regular checks, and logged access. If someone goes somewhere odd or at the wrong time, it leaves a record. Some might call that unnecessary, but stories of accidental exposure always start with “someone thought it was something else.”

It’s not enough to post a list of what to do after a spill. Regular drills get everyone involved, even the manager who usually avoids the bleach smell of the storeroom. Proper goggles, gloves, acid-resistant aprons—these belong close to the door, not buried under old paperwork. Every person working with the acid should know how to use a spill kit and neutralizing solutions. I once saw a small accident turn into a big problem because staff had to run upstairs for supplies—every second counts with corrosives.

After working alongside chemists, cleaning crews, and logistics teams, I know the best safeguards start with people looking out for each other. Store Toluenesulfonic acid with the same care you’d demand from anyone handling dangerous materials. Practical steps, not just policies, make the difference between a lab that feels secure and one constantly on edge. Trust comes from doing it right every time.

Anybody who’s handled chemicals in a lab or factory knows the moment you spot a name like Toluenesulfonic acid on a label, it’s time to pay close attention. This chemical, known for its use as a catalyst and in organic syntheses, brings its own hazards. Skin and eye contact can cause painful burns. Breathing in the fumes leaves airways irritated. Add water or moisture and the reaction heats up fast, releasing strong fumes. It only takes a small mistake for things to go sideways. In every lab I’ve worked, stories circulate about what happens when someone gets careless with corrosive acids. It’s a lesson you remember.

The first rule that sticks when working with anything like Toluenesulfonic acid: suit up right. Forgetting goggles or gloves leads to trouble. I’ve seen a single splash on exposed skin leave a scar. Chemical splash goggles and a face shield handle the risk of accidental sprays. Nitrile gloves last through typical tasks, but check for degradation. For heavy-duty jobs or cleanup, use an apron or lab coat made from acid-resistant material.

Fumes sneak up on you. Without proper ventilation, invisible vapors float in your workspace. Anybody mixing or transferring the acid inside a fume hood keeps the air safer. Not every small lab installs expensive systems, but even opening a window and directing air with fans makes a difference, especially if the job lasts more than a few minutes. Wearing a mask with the right acid-resistant cartridge helps for those times proper ventilation falls short.

Organization and labeling prevent panic later. Toluenesulfonic acid reacts with water and bases, so somebody always checks that containers stay tightly sealed with no leaks. I’ve found clear, bold labels save time and prevent confusion, particularly for those new to the team. Always store acids away from bases, oxidizers, and anything flammable. Even a small spill spreads fast if containers aren’t closed securely.

Cleaning up a small spill properly separates a safe response from a disaster. Neutralizing agents like sodium bicarbonate should sit nearby, along with absorbent materials designed for acid. Practice helps: our training drills meant nobody froze when acid hit the table. Full instructions on what to do—wash affected skin, rinse eyes at the eyewash station for 15 minutes, remove contaminated clothing—hang on the wall for fast reference. We report incidents quickly, no matter how minor, so everyone stays aware and procedures improve over time.

Rules alone won’t protect anyone. Having a culture where questions get answered and new staff practice runs builds confidence. Mistakes often come from rushing or cutting corners. From personal experience, reviewing the basics at the start of every semester in the teaching lab helps build healthy habits, not just for that one class, but for a career. Keeping up with safety data sheets and shift briefings sets the right example for anyone handling acids.

An emergency plan means more than a poster on the wall. Local poison control and emergency contacts get programmed into phones. Eye wash stations and safety showers need to stay clear, tested monthly. Knowing exactly where to run and what to do when something goes wrong reduces panic and limits injuries. Years in the lab taught me that good preparation turns risk into routine.

| Names | |

| Preferred IUPAC name | 4-methylbenzenesulfonic acid |

| Other names |

PTSA p-Toluenesulfonic acid Tosic acid Tosyl acid p-TsOH Toluene-4-sulfonic acid |

| Pronunciation | /ˌtoʊljuːˌiːn.sʌlˈfɒn.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 104-15-4 |

| Beilstein Reference | 3590673 |

| ChEBI | CHEBI:28718 |

| ChEMBL | CHEMBL504188 |

| ChemSpider | 7749 |

| DrugBank | DB11105 |

| ECHA InfoCard | 100.004.147 |

| EC Number | 207-635-4 |

| Gmelin Reference | C137360 |

| KEGG | C01401 |

| MeSH | D014027 |

| PubChem CID | 6076 |

| RTECS number | WN0700000 |

| UNII | 40D5MG394T |

| UN number | UN2586 |

| CompTox Dashboard (EPA) | `DTXSID9086523` |

| Properties | |

| Chemical formula | C7H8O3S |

| Molar mass | 172.20 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.24 g/cm³ |

| Solubility in water | Very soluble |

| log P | -2.2 |

| Vapor pressure | <0.01 mmHg (20°C)> |

| Acidity (pKa) | -2.8 |

| Basicity (pKb) | -7.8 |

| Magnetic susceptibility (χ) | -6.6 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | nD 1.591 |

| Viscosity | 30 cP (25°C) |

| Dipole moment | 2.83 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 188.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -900.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1681 kJ/mol |

| Pharmacology | |

| ATC code | V03AB37 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H302, H314 |

| Precautionary statements | P280, P264, P301+P330+P331, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 3-0-2-Acidos |

| Flash point | 145°C |

| Autoignition temperature | 450°C |

| Lethal dose or concentration | LD50 oral rat 2480 mg/kg |

| LD50 (median dose) | = 1410 mg/kg (Rat, oral) |

| NIOSH | UNII825V41CISC |

| PEL (Permissible) | Not established |

| REL (Recommended) | 5 mg/L |

| IDLH (Immediate danger) | IDLH: 80 mg/m³ |

| Related compounds | |

| Related compounds |

Benzenesulfonic acid p-Toluenesulfonyl chloride Mesitylenesulfonic acid Sulfanilic acid Benzenesulfonate Methanesulfonic acid |