Before synthetic surfactants changed the cleaning world, soap ruled the industry, bringing its own baggage: soap left scum in hard water, clogged machinery, and couldn’t handle oily residues well. In the 20th century, researchers chased better alternatives, focusing on sulfonic acid derivatives. Out of that race, sodium dodecyl benzene sulfonate (SDBS) appeared during the 1930s and 1940s, giving manufacturers a shot at reliable detergency without the sticky drawbacks of traditional soap. Chemists found that blending benzene, sulfuric acid, and dodecyl alcohol delivered a molecule that lathered up, cut grease, and played nicely even with mineral-rich water. The breakthrough didn’t just help the laundry pile. It spilled into agriculture, textiles, and even crude oil extraction, shifting the way people cleaned and processed almost everything.

Walk down any supermarket aisle packed with cleaning products, and you’ll bump into some version of dodecyl benzene sulfonate. This surfactant makes up the backbone of countless laundry powders, dishwashing liquids, industrial degreasers, and car wash foams. Its main trick lies in breaking the surface tension between water and grease, making dirty water simply drain away. Many brands use SDBS because it keeps costs manageable while offering consistent performance. Its recognizable name pops up on ingredient lists under both trade and technical titles, marking its spot as a true staple in mass-market cleaning and industrial formulas.

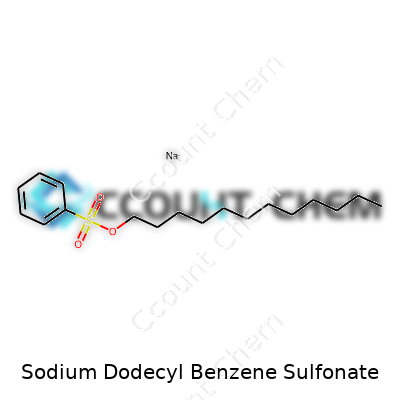

As a white or yellowish powder or granule, sodium dodecyl benzene sulfonate dissolves easily, sometimes foaming up before you even get it in the water properly. The molecule carries a long alkyl chain (dodecyl) attached to a benzene ring sulfonated at one position, finished off with a sodium counterion. Melting points push past 200°C, and it stands up to most acids and bases. Solubility plays a key role: easy dissolution lets it tackle soils and oils in any water, hard or soft. With strong wetting action, it quickly reduces water’s surface tension, letting the detergents get into fabrics and onto dishes fast so nothing hangs around past cleaning.

Manufacturers stick to tight specifications to keep quality up. SDBS often comes with an active content exceeding 85%, a low unsulfonated matter percentage, and a pH value that leans slightly alkaline. Labels reflect these benchmarks, including the concentration of active ingredient, moisture content, and advice on handling. Some standards—like those from the International Organization for Standardization (ISO) or local authorities—push producers to document traceability and batch details, giving users confidence about what’s inside the bag. Clear hazard identification, transport, and storage recommendations guard both workers and the environment.

Production follows a set chemical dance. Starting with linear dodecyl benzene, the material gets treated with concentrated sulfuric acid through sulfonation. This reaction brings the sulfonic acid group onto the aromatic ring. Neutralization with sodium hydroxide wraps up the process, converting the acid into its sodium salt. Any leftover impurities or reaction byproducts get rinsed or filtered off, making sure only the pure surfactant makes it to packaging. Industrial reactors handle thousands of kilos at a time, controlling temperature and mixing speed to achieve consistency batch after batch. Tweaking the chain length or introducing different alkyl groups allows some control over solubility and foam qualities for later product customization.

The molecule sits ready for both chemical and physical modifications. Strong oxidizing agents may break down the benzene ring, so producers avoid mixing with such chemicals during manufacturing or storage. Sometimes, companies modify the alkyl side chain by branching or blending with other hydrocarbons, fine-tuning the balance between solubility and detergency. These little shifts turn the basic molecule into a surfactant tailored for light-duty dish soaps or heavy-duty degreasers. Adding builders, anti-redeposition agents, or blending with other surfactants unlocks a wide range of applications, letting formulators match SDBS to just about every kind of dirt out there.

In catalogs and chemical inventories, sodium dodecyl benzene sulfonate pops up under a stack of synonyms, including SDBS, LAS (linear alkylbenzene sulfonate), and sodium alkyl benzene sulfonate. Each name points to the same basic structure, but some brands coin their labels for easier marketing or patent protection. Well-known cleaning products often list it as “anionic surfactant” or “sodium alkyl benzene sulfonate.” Despite the different names, the core molecule does the heavy lifting across laundry, household, and industrial cleaning lines, linking these products together behind the scenes.

Handling powdered SDBS triggers standard chemical safety approaches. Gloves and goggles protect skin and eyes, as concentrated forms can irritate on contact. Dust clouds don’t just annoy; they cause respiratory issues if inhaled over long stretches. Big manufacturing sites install local ventilation, and workers keep dust masks handy. Regulatory agencies in the US, Europe, and beyond call for proper hazard labeling, clear first-aid instructions, and robust storage conditions. Environmental rules restrict direct release to waterways because SDBS, while biodegradable under the right conditions, sticks around and harms aquatic life if dumped in bulk. Wastewater treatment plants use both aerobic and anaerobic methods to break the molecule down as far as possible before water returns to the environment.

Community laundromats, auto service stations, food processing plants, and even municipal water pipelines all lean on sodium dodecyl benzene sulfonate in one way or another. In home use, it anchors powdered and liquid laundry detergents, scoring points for removing soils from both natural and synthetic fabrics. Restaurant and catering industries trust it in dishwashing and floor-cleaning solutions, because it rapidly strips away fat, protein, and grime. Farmers use blends with SDBS as wetting and dispersing agents for pesticides and herbicides, as its surfactancy helps chemicals reach plant surfaces evenly. Municipalities find SDBS useful in firefighting foams and wastewater treatment, where it supports oil-water separation or emulsification in difficult cases. In the lab, its ability to break open cell membranes lets researchers extract DNA or analyze proteins without fuss.

Research teams in both corporate and academic labs keep tinkering with SDBS, aiming to dial down its drawbacks while boosting benefits. Green chemistry efforts drive the search for alternative feedstocks, such as plant-based dodecyl chains or more readily biodegradable sulfonates. With growing regulatory scrutiny across the globe, investigations continue into both acute and chronic impacts on wildlife, soils, and humans. Some R&D projects test how combinations with new enzymes or chelators could lift tough stains in cold water, cutting household energy bills without losing cleaning power. Other studies examine advanced purification steps in the factory, looking for ways to minimize byproducts or energy use in production lines.

People sometimes worry about surfactant safety, especially with so many chemicals washing down household drains every day. Toxicology tests show that SDBS causes mild to moderate irritation in concentrated forms on the skin, eyes, and lungs. If swallowed in large amounts, it upsets digestion, but the risk drops significantly at the dilute concentrations found in commercial products. Environmental studies, though, point to trouble for fish and invertebrates at high exposure levels, as even small residues in rivers affect gill function and reproductive cycles. Regulators base safe limits for surface and drinking water on these studies, pushing for better biodegradation and more effective wastewater treatment. Long-term follow-ups still focus on breakdown products, as some byproducts of incomplete treatment throw up new challenges for water quality monitoring and toxicology labs trying to protect people and the environment.

Detergent makers and environmentalists eye the future of sodium dodecyl benzene sulfonate from different angles. The pressure to reduce chemical loads in waterways and make consumer products safer grows every year. Eventually, strict rules could usher in even tighter limits on non-biodegradable chemicals. Some companies invest in next-generation surfactants based on renewable and low-impact ingredients, racing to offer options just as powerful but with smaller footprints. Sustainable packaging, smarter dosing, and improved enzyme technology all circle back to minimizing the amount of SDBS needed to get the same clean. The future likely won’t cut SDBS out entirely—it still anchors too many critical uses—but constant R&D promises a steady drift toward safer, cleaner, and greener alternatives across the board.

Walk down the grocery store aisle lined with detergents, and you’re looking at the handiwork of sodium dodecyl benzene sulfonate (SDBS). This mouthful of a chemical quietly works in almost every liquid cleaning product. It grabs oils and dirt and holds them suspended in water, letting us wash greasy plates, messy hands, and dirty cars without much scrubbing.

Years ago, scrubbing laundry took elbow grease and time. The introduction of chemicals like SDBS set people free from endless scrubbing. The main job here is all about breaking the tension between water and greasy stuff. This chemical acts as a surfactant, which simply means it helps water mingle with oil and dirt. Once dirt mixes in, clothes, surfaces, and skin get cleaner without much work.

The label on a bottle rarely calls out SDBS by name, but it does the heavy lifting. If you notice dish soap that foams up fast, that's probably SDBS at work. It works efficiently in both hard and soft water. Cleaning power doesn’t drop off when the tap water feels chalky.

SDBS doesn't only show up at home. Car washes, industrial floors, and even some agricultural sprays lean on its cleaning muscle. Its popularity comes from both its cost and effectiveness. Factories use SDBS in products ranging from degreasers to fabric softeners. Paint factories and concrete mixers also add it for its ability to lower surface tension, so their products spread out evenly and dry correctly.

In the world of cleaning, less time bent over a tub or scrubbing floors means people can focus on what really matters to them. Living with allergies taught me that lingering detergents after a rinse can cause skin irritation, so seeing surfactants that rinse away completely feels important. SDBS usually washes out well, lowering the chance of leftover chemicals.

Convenience often has a flip side. With growing use, SDBS gets rinsed down drains and flows into rivers. Some studies show it doesn’t break down quickly in the environment. This raises concerns about fish or aquatic insects coming into contact with residue. While research continues, some countries have started setting discharge limits. Environmental regulators encourage factories to capture and treat their wastewater before it gets to rivers or lakes.

From my own experience, environmentally friendly soaps use alternatives to SDBS or blend it with more biodegradable companions. European health groups and the US Environmental Protection Agency regularly review ingredients like SDBS for safety. They focus on making sure it doesn’t build up in people or wildlife.

People want cleaners that work without causing new problems for the planet. Companies can look for ways to manufacture SDBS with fewer toxic byproducts. Water treatment plants and stricter regulations can help keep waterways safe. As public demand for safer and greener products rises, the chemistry world raises its standards.

Sodium dodecyl benzene sulfonate has earned its place in modern life. It helps shorten chores and raise hygiene standards, but it comes with responsibility. Regular discussions between scientists, regulators, and the public can help everyone keep an eye on both health and the environment.

Plenty of folks have come across sodium dodecyl benzene sulfonate in ingredient lists, especially in dish soaps or laundry liquids. It’s a cleaning workhorse, famous for its ability to make water and grease mix. With all these everyday encounters, it’s fair to wonder what that really means for skin.

Sodium dodecyl benzene sulfonate acts as a surfactant. It turns greasy dishes clean and helps wash away dirt from fabrics. For anything that cuts stubborn grime this well, people deserve some transparency about whether it is gentle enough for human skin, especially after repeated use.

Most common household cleaning products use only a small percentage of this ingredient. At these levels, sodium dodecyl benzene sulfonate tends not to trigger serious reactions in people who don’t have extra-sensitive skin. The American Cleaning Institute and multiple published toxicology assessments report minimal risk of long-term harm from brief, occasional skin contact for healthy adults. Rinsing thoroughly and avoiding open wounds protects against most problems.

But let’s get real: surfactants work by breaking down oils and fats. Human skin makes natural oils for a protective barrier, so frequent, concentrated exposure to any strong surfactant can leave hands dry, red, or itchy. If someone already deals with eczema or allergies, that stinging sensation comes on fast. A patch test or consulting a dermatologist stays a smart move if irritation shows up, especially for children.

Problems crop up when the ingredient comes in high concentrations or sits on skin for too long. Industrial or commercial-strength products usually warn users to glove up. In a home setting, diluted household cleansers get rinsed away quickly, bringing risk way down. Anyone mixing cleaning liquids or refilling bottles should avoid touching the undiluted stuff, and wash hands if it happens by mistake. Label instructions aren’t just for show; they reflect hard lessons from lab tests and worker experience.

Plenty of people keep their skin in good shape by simply wearing rubber gloves for repeated cleaning jobs. Moisturizing with a basic hand cream after chores replaces what detergents remove. Choosing products labeled “mild” helps those sensitive to irritation, often meaning the concentration lands on the lower side or formula makers add humectants to lighten the load on skin. Some brands now skip certain surfactants altogether in their “sensitive skin” or “baby” lines.

Regulators and product makers keep a close eye on these issues. In many countries, agencies such as the US Environmental Protection Agency and the European Chemicals Agency keep setting thresholds for safe use in personal care and cleaning supplies. These rules adjust as new studies come out, and companies watch their customer complaints closely. For me, trust rests in transparency and proven track records. If a brand offers detailed ingredient and safety info, it usually means they take feedback and safety seriously.

Sodium dodecyl benzene sulfonate brings big cleaning power, but with that comes a need for some respect for its science. Sticking to diluted household formulas, rinsing well, and skipping overexposure keep the risk of trouble from surfactants to a minimum. For those with skin already on edge, it pays to check ingredient labels or switch to a milder product.

Sodium Dodecyl Benzene Sulfonate shows up in plenty of products—think cleaning supplies, detergents, and even some industrial applications. Over the years, I've spent a good chunk of time working with bulk materials, and I can tell you that how you keep a chemical like this makes a world of difference. Anyone who's ever found a leaking drum in a crowded storeroom knows that safe storage isn't something to brush off.

Direct sunlight spells trouble for Sodium Dodecyl Benzene Sulfonate. Too much light speeds up chemical breakdown, turning what once was a pretty stable product into something less predictable. Keeping it away from heat matters, too. High temperatures push the chemical toward decomposition, and that can mean the release of nasty fumes that nobody wants to breathe in. Cool, shaded, and dry—these three words save time, money, and peace of mind.

Moisture creates more problems than people often assume. If this chemical absorbs water from the air, it clumps up or reacts, possibly creating spills or shifts in performance for whatever product uses it next. I've seen bags stacked on rough concrete, tops open, collecting humidity and turning solid. Closing containers tightly and storing them off the ground protects the product and everyone around.

Not all containers work the same way. Polyethylene drums or high-quality plastic bags lined with moisture barriers stop water from getting in and product from getting out. Metal drums sound sturdy, but unless lined properly, they invite rust. Rust changes the surface of drums and, over time, can mess with the chemical inside. Once, I came across containers with a thin break in the seal—the powder inside had caked up and released a faint, sharp odor. Better packaging saves real headaches down the line.

Keeping spill kits handy and training staff on clean-up techniques remains a must. Sodium Dodecyl Benzene Sulfonate washes away with lots of water, but if it heads down a drain in large amounts, it foams up and disrupts water treatment. Years ago, I watched a team scramble to scoop up powder with scoops and dustpans while one person blocked the drains with rolled towels. Quick action stopped a tough situation from getting worse, but only because supplies and know-how were ready.

Too often, stored chemicals lose their labels over time. Someone stacks boxes on top, or condensation makes ink run. Without proper identification, confusion leads to mistakes. I always encourage labeling every container in plain, bold print. It takes almost no time and beats guessing. Local fire departments and environmental agencies often update storage rules, so revisiting rights and wrongs every year keeps storage safe and operations on solid ground.

Everyone in the supply chain—from delivery driver to warehouse manager—benefits from good storage. Training, airtight packaging, and routine checks do more than protect investments. They guard health, keep products consistent, and give peace of mind to anyone working near these chemicals. Storage might seem like a backroom detail, but it truly shapes safety at every level.

Sodium dodecyl benzene sulfonate crops up in dozens of everyday products. It foams in cleaning sprays, gets grime off kitchen counters, and powers through laundry stains. Most people run into it long before they ever read the label. Despite its cleaning power, using this surfactant carries some strong risks.

In my own home, I’ve noticed that regular contact with concentrated cleaners sometimes means itchy hands. Dermatologists trace this reaction back to sodium dodecyl benzene sulfonate, which disrupts the natural oils on human skin. Even diluted products cause problems for people with eczema or sensitive hands. Stronger concentrations burn the eyes. Laboratory safety sheets warn: splashing a little in the wrong place gets serious fast. Workers in factories making this chemical wear gloves and shields for a reason—health authorities in the U.S. and Europe list it as an irritant.

Inhaling the dust or vapor is risky, too. A poof of powder or mist while measuring out industrial surfactant stings the nose and throat. Some workers spend years breathing it in and face chronic coughs or wheezing. The International Chemical Safety Card for sodium dodecyl benzene sulfonate recommends well-ventilated spaces and dust protection.

Environmentalists bring up another big problem. After scrubbing countertops, all that surfactant washes down the drain. Sewage plants pull much of it back out, but some escapes into local rivers and lakes. Studies from the U.S. Environmental Protection Agency show that levels above 2 mg/L cause fish and water bugs to die back. Surface films from the chemical cut off oxygen for aquatic life. Over months, that damage stretches up the food web, affecting birds and small mammals.

Once in water, sodium dodecyl benzene sulfonate breaks down slowly. In cold climates, or poorly managed wastewater systems, it lingers for weeks. Its persistence worries scientists tracking the rise of chemical “pollutants of emerging concern.”

Looking over the science, most negative health effects stem from high, regular exposure. At low doses in household products, experts haven’t found strong links to cancer. Even so, hospital records confirm that repeated exposure to cleaning sprays puts custodians at higher risk for asthma and allergies. That lines up with stories from people who clean for a living—after years on the job, they cough and sneeze every winter. In my own family, we switched away from heavy-duty cleaners after noticing the kids’ hands got red and flaky.

Smart habits cut down the risk. Check labels and pick products with less sodium dodecyl benzene sulfonate. Gloves and eye protection matter during deep cleans. Set up good ventilation—open the windows or run an exhaust fan. Some companies already look for gentler plant-based options that do the job without the strong chemical load.

Communities can also ask cities to improve wastewater treatment so less surfactant reaches streams and rivers. Regulators need reliable testing and stricter discharge rules. Where governments and manufacturers invest in safer formulas, that has ripple effects down to household safety and the health of local rivers.

Open most cupboards and you’ll spot a bottle of liquid detergent. Behind the scenes, some complex chemistry keeps laundry and dishes sparkling clean. Sodium dodecyl benzene sulfonate (SDBS) plays a starring role in that process. Its stain-busting power became a staple in household products for decades, raising a big question—what happens after the rinse water flows down the drain?

Every time wastewater flows into treatment plants or local waterways, the chemical leftovers start a new journey. SDBS is not just a mouthful—it’s a synthetic anionic surfactant. In the 1960s, SDBS largely replaced older soap compounds, since it didn’t react with hard water minerals and cause soap scum. Many see it as a major upgrade, but fewer people know about the challenges SDBS brings to the table.

Treatments plants today work night and day to break down detergent molecules. Research over the past few decades shows SDBS does break down—eventually. It’s considered “readily biodegradable” in lab environments, particularly with the right bacteria and enough oxygen around. Regulatory agencies, including the Organization for Economic Co-Operation and Development (OECD), confirm SDBS can degrade by over 90% in controlled testing. Yet, wastewater treatment in the real world doesn’t always play by laboratory rules.

I’ve walked past urban creeks that bubble with foam after a heavy rain, a sure sign that not every molecule breaks down in the city’s treatment system. In places where plants struggle to keep up—due to high pollution loads or equipment failures—SDBS has a harder time degrading. Low oxygen, cold temperatures, and the mix of other pollutants can slow the breakdown process. So, while SDBS clears most hurdles under ideal conditions, it lingers in waterways when local infrastructure falls short.

The bigger trouble comes from SDBS’s design. That long hydrocarbon tail can resist attacks from nature’s own clean-up crew, meaning residues sometimes persist in riverbeds and shorelines. One study from Germany found traces in sediments, especially where discharges from household drains pile up. The substance can harm aquatic life by damaging gills of fish or interfering with how plants take up nutrients.

Growing up, I never thought twice about what household cleaners contained. In recent years, product labels started to mean something extra. Countries such as Germany and Sweden have pushed detergent makers to swap out persistent surfactants for those that break down faster. The switch comes from pressure—consumers now demand products that leave less junk behind.

Municipalities invest heavily in upgrading treatment systems, but even the best technology only works so fast. The real challenge starts at the store and in homes. People pick the cheapest and strongest products off the shelf. Manufacturers feel pressure to hit the right price and performance. Without everyone pulling together, residues from SDBS and other surfactants keep slipping through.

Governments could set tighter limits for what’s allowed in cleaning products. Educators could help teach the next generation why water protection matters. Choosing brands that publish greener chemistry claims—and prove it through lab tests—moves the conversation forward. The right formula needs both improved chemistry and a shift in how water services operate. Until both sides work in sync, chemicals like SDBS will keep turning up where they don’t belong.

| Names | |

| Preferred IUPAC name | Sodium 4-(dodecyl)benzenesulfonate |

| Other names |

Linear Alkylbenzene Sulfonate Dodecylbenzenesulfonic acid sodium salt LAS Sodium Laurylbenzenesulfonate Sodium alkylbenzene sulfonate |

| Pronunciation | /ˈsoʊdiəm doʊˈdɛsɪl bɛnˈziːn ˈsʌlˌfoʊneɪt/ |

| Identifiers | |

| CAS Number | 25155-30-0 |

| Beilstein Reference | 3567936 |

| ChEBI | CHEBI:31813 |

| ChEMBL | CHEMBL2097253 |

| ChemSpider | 7956 |

| DrugBank | DB11140 |

| ECHA InfoCard | 100.024.262 |

| EC Number | 246-680-4 |

| Gmelin Reference | 80120 |

| KEGG | C19206 |

| MeSH | Dodecylbenzenesulfonates |

| PubChem CID | 23614 |

| RTECS number | DB6600000 |

| UNII | W0AF4JNXA7 |

| UN number | “UN 2586” |

| CompTox Dashboard (EPA) | DTXSID2022843 |

| Properties | |

| Chemical formula | C18H29NaO3S |

| Molar mass | 348.48 g/mol |

| Appearance | White to light yellow powder |

| Odor | slight characteristic odor |

| Density | 0.18 g/cm³ |

| Solubility in water | soluble |

| log P | -2.8 |

| Vapor pressure | Negligible |

| Acidity (pKa) | -6.5 |

| Basicity (pKb) | 12.6 |

| Magnetic susceptibility (χ) | -61.0e-6 cm³/mol |

| Refractive index (nD) | 1.485 |

| Viscosity | 30-60 mPa·s (20°C, 20% solution) |

| Dipole moment | 7.6 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 362.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -567.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -7516 kJ/mol |

| Pharmacology | |

| ATC code | D08AX |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and serious eye irritation, may cause respiratory irritation |

| GHS labelling | GHS07, GHS05, GHS09 |

| Pictograms | GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H315: Causes skin irritation. H318: Causes serious eye damage. |

| Precautionary statements | P264, P270, P273, P280, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 3-0-2-ALC |

| Flash point | > 140°C |

| Autoignition temperature | 400°C |

| Lethal dose or concentration | LD50 Oral Rat 1,080 mg/kg |

| LD50 (median dose) | 438 mg/kg (rat, oral) |

| NIOSH | DB5950000 |

| PEL (Permissible) | PEL: 15 mg/m³ (total dust), 5 mg/m³ (respirable fraction) |

| REL (Recommended) | REL (Recommended Exposure Limit) for Sodium Dodecyl Benzene Sulfonate is: **Not established** |

| Related compounds | |

| Related compounds |

Alkylbenzene sulfonate Linear alkylbenzene sulfonate Dodecylbenzenesulfonic acid Sodium lauryl sulfate Sodium laureth sulfate |