The roots of Sodium 3-(2-Propyn-1-yloxy)-1-propanesulfonate date back to the growth of organic synthesis in the late twentieth century when chemists started lining up alkyne-containing molecules with sulfonate groups. Synthetic achievements in industrial labs and universities set the scene for wider use. This compound soon became a key piece in the puzzle for scientists chasing better surfactants and functional polymers, especially as research ramped up in the field of electrochemistry. American, European, and Japanese teams reported new preparation routes around the 1990s, trying to balance between yield, purity, and cost. Those early days boiled down to one thing: making life easier for chemists building blocky molecules for everything from anti-fouling paint to drug delivery.

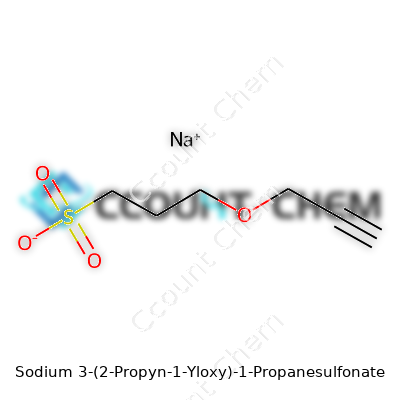

This sodium salt never grabbed headlines, but lab folks know it by its unique balance of alkyne reactivity and water-soluble sulfonate. The structure brings together a propynyl and a propanesulfonate, tied by an ether bond, giving it a punchy character. It looks like a white or slightly off-white powder, dissolves readily in water, and doesn’t put up much fuss in most lab solvents. In industry, suppliers offer it in bags with desiccant packs because it pulls in water and clumps if left exposed. The biggest point here isn’t its pedigree, but the way it tees up for functionalization and advanced materials.

Physical specs reflect what you see in a typical alkyne sulfonate. Melting point sits above room temperature—sometimes reported near 160°C—though handling rarely gets that hot. Solubility in water outshines most organic salts, with full dispersion at concentrations needed for polymerization, electroplating, or analytic applications. The molecule carries a strong sulfonate group, giving it a low pH in solution. Alkyne groups crave new partners, opening the door for click chemistry or further functionalization by azide-alkyne cycloaddition. It holds up under mild oxidants but decomposes in strong acid or under prolonged heating. In day-to-day lab work, stability stays high enough for short- and mid-term projects.

Commercial products list a purity of 97% or above, sometimes even above 99%. Packaging usually sticks to amber glass or plastic, labeled for light sensitivity and moisture sensitivity. Batch numbers tie back to manufacturing cycles, with typical safety data reminding users about eye and skin protection. Suppliers print UN numbers and GHS hazard statements, often noting “irritant” status. Trace metals or organic impurities fall under detection limits, as the sulfonate group tends to sweep up stray ions in solution. Shelf life usually clocks in at over twelve months if capped and stored in a cool, dry room, out of direct sunlight.

Labs and factories approach its production through etherification, tying a propargyl alcohol to a 3-chloropropanesulfonic acid sodium salt under basic conditions. Some go for phase-transfer catalysis to boost the yield, others lean on polar aprotic solvents such as DMF or DMSO to minimize byproducts. Reaction control comes down to temperature and pH, as excess base swings the outcome toward side reactions. Workup demands a careful extraction and washing to drag out any unreacted organics, plus solvent removal on a rotary evaporator for smaller batches. Larger volumes get drum-filtered and dried under vacuum. The needs here are clean water, tight control of pH, and enough scrub air to handle the faint whiff of sulfur that drags along.

Out in the field, this molecule joins click reactions, especially in the famed copper-catalyzed azide-alkyne cycloaddition. Its alkyne snaps onto azides, stapling new groups to the sulfonate backbone. Chemists take the sodium salt as a starter, tagging it with fluorescent labels or biotin to explore biomaterials. The sulfonate enables water solubility in mostly hydrophobic lines, so polymers built from it stay dissolved and easy to process. Other labs modify the chain for crosslinking in hydrogels and membranes, using the terminal alkyne as a junction point. In a push for greener chemistry, researchers use microwave reactors or water as solvent, avoiding heavy metals or nasty cleanup steps.

Don’t get lost in the data sheets or catalogs: this compound pops up under several aliases. Propargyl-oxypropanesulfonate sodium salt and sodium 3-(prop-2-yn-1-yloxy)propanesulfonate turn up. Older literature may call it sodium 3-(propynyloxy)-1-propanesulfonate. Vendors pack it under catalogue numbers that vary by distributor. So if you’re ordering, check the IUPAC spelling, cross-check the CAS number (commonly reported as 89792-93-2), and ask for a spectral copy. Avoiding confusion beats running a mis-labeled batch and burning a day cleaning up.

Lab safety officers peg this chemical as an irritant—gloves, eye protection, and good ventilation keep handling clean. Spills kick up fine dust; I keep a HEPA vac on hand and avoid dry sweeping. It stings in the nose if inhaled too deeply, so a dust mask helps during weighing. Storage needs an airtight container with desiccant; keeping it dry matters, since clumping ruins measured dosing and spoils solution recipes. Disposal teams follow local rules for sulfonates and alkynes, usually collecting it for hazardous waste treatment rather than a regular sink dump. Most safety data sheets warn not to breathe the dust or let it contact skin for extended periods; my own practice adds a habit of washing up right after handling, even though I haven’t met anyone burned by it yet.

Few molecules help electroplating and surface modification like Sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate. In plating baths, it smooths metal deposition and fights roughness, especially in copper and gold electroplating. Polymer chemists lean into its dual nature: the alkyne group for snap-reactions, the sulfonate for dissolving in water or polar solvents. Research teams blend it into hydrogels for tissue scaffolds, or as part of drug delivery systems, where solubility and stability mean fewer headaches. Analytical scientists add it as a mobile phase modifier in capillary electrophoresis, banking on the sulfonate’s charge to shift analyte migration. Its reach into anti-fouling coatings and adhesives grows as the market for specialty polymers covers more ground.

Over the last decade, more teams publish findings on ways to attach bioactive molecules, tune swellability in hydrogels, and anchor catalysts for water purification. Small startups and national labs compete on processing techniques, chasing lower production costs and higher batch quality. Some researchers, including former colleagues of mine, focus on making derivatives with longer chains or extra functional groups, hoping for breakthroughs in selective binding or smart-release coatings. Patent filings often circle around new uses, prep methods, or hybrid materials with medical applications. Keeping track of competitive landscapes takes time, but companies stake out new IP rapidly as they sense growing demand for specialty surfactants and advanced polymers.

Testing for toxicity stays high on the priority list. Most reports peg this compound as low toxicity to mammals but urge caution; it irritates eyes and mucosa, especially in powder form. No long-term studies show clear links to carcinogenicity or chronic toxicity, but data remains thin, especially when you step away from rodent studies. Environmental watchdogs look for high solubility as a double-edged sword: its breakdown in water treatment plants gets close scrutiny, and teams run biodegradability studies to keep up with evolving regulations. Waste streams carrying this compound get monitored for aquatic toxicity, though most findings so far show quick degradation when diluted. In my own projects, strict glove use and proper waste handling have kept incidents at zero, but all labs should run their own risk checks regularly.

Looking down the road, prospects shine in new material science and sustainable chemistry. As the market for advanced hydrogels and membrane technologies heats up, this sodium salt earns more attention for its ability to connect functional groups in water without relying on harsh solvents. Teams at research universities test its use in stimuli-responsive coatings, while green chemistry advocates push for safer, high-yield prep methods. Contract manufacturers angle to scale up production, hoping regulatory approvals will unlock bigger sales. If new toxicity data keeps hazard ratings low, adoption in biotech and food packaging may follow, provided suppliers can guarantee purity and batch consistency. The next few years may show if industry picks up what academic labs build with molecules like this, or if cheaper alternatives crowd it out of high-value niches. Progress depends less on hype and more on the hard work of troubleshooting, quality control, and transparency about what this compound really brings to the table.

Sodium 3-(2-Propyn-1-yloxy)-1-propanesulfonate doesn’t get much attention outside the labs. Its long name turns most eyes away. But, this compound slides quietly into more conversations inside research circles than many folks realize. Its true value starts to show once you look past the intimidating jargon and see what it brings to the table, especially in the world of polymer science and electronics.

Years tinkering in chemistry spaces have shown me how little things can shape a project. Sodium 3-(2-Propyn-1-yloxy)-1-propanesulfonate acts as a classic example. Chemists put it to work in water-soluble polymers, especially in crafting specialty resins. The group attached to its backbone—the propargyl and sulfonate—makes it a popular choice for creating so-called “functionalized” polymers. These polymers behave differently from the off-the-shelf stuff, especially after modifications using “click chemistry,” a reaction that has taken chemistry labs by storm for its speed and reliability.

In my experience, labs turn to this chemical as a building block for materials that interact well with water. Those materials end up in everything from wastewater treatment solutions to conductive coatings. Thanks to its unique structure, it bridges the gap between traditional plastics and highly engineered compounds made for electronics, sensors, or medical devices. These sulfonate groups boost the solubility and improve ion-exchange, which gives rise to materials with new abilities—think membranes that separate ions for batteries, or hydrogels that trap molecules for diagnostics.

A product’s worth comes down to its role on the job. Here, sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate helps create polymers that clean our water, help harness energy, or make devices respond to their environment. These applications impact daily routines, even if folks never hear the chemical’s name.

I’ve seen how innovation outpaces regulation. Without clear safety and disposal rules, specialty chemicals risk slipping into supply chains unchecked. Reports dating back to 2011 show the adoption of click-chemistry approaches rose fast, often without enough toxicology data. This underlines the need for deeper evaluation before large-scale use. The challenge lies in the gap between curiosity-led advances and broad scrutiny.

Chemists, engineers, and manufacturers need a shared responsibility to vet new chemicals before adding them to mass production. Public science funding bodies and academic journals hold the purse strings and the keys to spreading knowledge. They can add weight to research that digs into both benefit and risk.

Industry certifications offer another approach. When suppliers support third-party verification for specialty chemicals, it forces a closer look at long-term effects, chronic toxicity, and environmental impact. Calls for transparent labeling and data-sharing among manufacturers grow louder every year, as a result, traceability gets built into the system.

Looking ahead, investing in alternative approaches—like greener synthetic pathways or bio-based equivalents—can shrink unwanted side effects before they start. Experience shows that a safer product never holds back discovery; it only sharpens the tools we use to build the future.

People don’t always realize how much effort goes into keeping products fresh and reliable before they reach their hands. From personal experience in a busy food facility, the way items get handled behind the scenes often decides whether customers enjoy safe, high-quality goods or deal with spoiled, useless stock. Temperature swings, dampness, or letting containers stay open lead to big headaches. Once, a shipment of chocolate melted due to a broken fridge—no amount of cooling after the fact brought it back to shape or taste. These lessons highlight how taking shortcuts with storage often leaves you with bigger problems.

Dust, insects, and rodents love poorly maintained storage spots. Their presence isn’t just gross—it’s a health risk. Bacteria thrive where packages break or moisture collects. In my past work with warehouse teams, one misplaced mop left a slick spot that attracted flies and ruined a whole corner’s worth of stock. Simple habits—clean shelves, closed bins, swept floors—save companies from costly recalls and keep teams from scrambling on damage control. Regular cleaning schedules, paired with pest deterrents and inspections, cut down on these problems before they grow.

Certain products demand tighter controls. Pharmaceuticals break down when exposed to heat, while electronics suffer damage in damp conditions. Most manufacturers recommend storing in cool, dry areas, but each item comes with its own sweet spot. Dry goods like flour last longest below 20°C, shielded from sunlight. Refrigeration isn’t always the answer—excessive cold puts some products at risk by making them brittle or causing condensation inside packaging. Investing in temperature and humidity monitors helps workers act if conditions slip out of target range.

Misplaced labels or missing dates lead to wasted stock. Every time you walk into a poorly managed storeroom, you can practically smell the confusion. With clear labeling and rotating inventory—first-in, first-out—you stop expiration surprises. I remember a bakery forced to toss dozens of eggs just because their dates got smudged and staff grabbed from the wrong pile. Simple fixes like color-coded stickers and checklists make it easier for everyone on the shift to grab the right box without second-guessing.

Protective gloves, eye gear, and face masks aren’t just for show. I’ve watched coworkers handle cleaning agents without proper barriers and regret it later, nursing skin burns and headaches. Training staff to use protective gear and properly handle packaging—especially heavy containers—prevents injuries that sideline good workers and slow down the team. Developing a reputation for safety keeps turnover low and morale high.

It’s tempting to cram pallets wherever there’s space. Instead, keeping aisles wide and exit routes open gives everyone safer, quicker access and helps avoid accidents. Tall or top-heavy stacks should stay low or secure. Giving staff easy-to-read maps, quick-trainings, and checklists turns chaotic storage rooms into efficient hubs. Each of these simple actions not only keeps shareholders and regulators happy but also delivers better, safer products to everyday people.

Storage and handling only improve with routine inspections, real-time reporting, and strong communication. Companies do best by investing in modern tools—digital tracking, barcode systems, air quality sensors—so they spot trouble early. Regular workshops encourage buy-in from all team members, building a culture where everyone feels responsible. Nothing beats a workplace where people respect each product in their care, knowing a little extra effort means better results at the checkout and beyond.

Ask most people about sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate, and you’ll probably get some blank stares. It's a tough chemical name to say, let alone understand. Yet this compound shows up in more places than folks might realize—mainly as a specialty ingredient in industrial and research labs, sometimes in surface coatings or materials processing. It’s not something people find under the kitchen sink, but the question about its safety—both for humans and the environment—deserves real attention.

Most information about this chemical comes from data sheets used by factories or research groups. The first thing I do when I come across a chemical I don’t recognize is to check the Material Safety Data Sheet (MSDS). These sheets focus on immediate hazards—touch, inhale, ingest, or contact with eyes. Sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate usually shows up as an irritant. Accidentally splashing it on skin or eyes creates problems, and the dust can bother people’s lungs. That's not strange—lots of sulfonates and reactive industrial chemicals behave the same way. That said, the big question is: what happens with repeated exposure?

Here’s where the information gets thin. Scientists studying workplace exposure often look for chronic effects over time such as cancer risk, neurotoxicity, or organ impacts. Right now, sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate hasn’t landed on big hazard lists at places like the International Agency for Research on Cancer or the US National Toxicology Program. Research is lacking, mostly because it’s used in small quantities by a specialist group. Still, being unknown doesn’t equal safe. Common sense says protective gear, proper ventilation, and education for workers are essential.

Every chemical used in a process could eventually head out into the world—down the drain, into the air, or locked up in a landfill. Sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate is water-soluble, and sulfonate groups usually help chemicals “stick around” in rivers or lakes. This persistence worries ecologists, since long-lasting chemicals sometimes end up stressing fish or water bugs. I’ve seen similar substances star in studies showing their stubbornness against breaking down in nature. Buildup like this throws a wrench into how waterways and soil recover from pollution.

Toxicity to aquatic life is another consideration. Each chemical hits fish or plants differently, so lab results matter. From what’s publicly available, this compound falls in with the “irritant but not acutely toxic” crowd. Still, almost every professional working with synthetic organics learns that it’s easier to keep a problem from starting than to clean up a mess.

In the real world, regulations often lag behind the science. Instead of waiting for bad news, companies using sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate could take steps that build trust—substitution with greener compounds, closed systems to prevent release, and honest reporting of spill risks. Environmental regulators and academic scientists need to keep studying unfamiliar chemicals, since today’s small-scale additive sometimes becomes tomorrow’s widespread issue. Purchasers and workers can demand clearer safety procedures and ongoing monitoring. That’s usually the path that keeps both people and nature out of trouble.

A bag of white powder on a warehouse shelf might look pristine, but what’s inside decides its value, safety, and use. Purity isn’t just a marketing term tossed on a label. In the world of chemicals, it tells how many so-called “extras” you’re getting along with the main ingredient. For years in the lab, I found the tiniest impurity could throw an experiment sideways, wasting hours and money. A pharmaceutical company cares because the patient swallows the result; an electronics producer relies on it because stray atoms ruin an entire batch. Purity proves crucial outside the lab, affecting daily products from aspirin tablets to microchips.

Chemical suppliers publish detailed specification sheets, not just as paperwork, but as a kind of contract. Purity percentage pulls in most eyes right away, sure, but those “trace” elements or contaminants matter too, especially where product safety or legal compliance stands in the balance. For example, food processing facilities must keep heavy metals below strict limits to avoid health risks and regulatory fines. Specifications often list values for moisture content, particle size, and acidity—each shaping how a chemical behaves or reacts. Years of troubleshooting have shown me that skipping over these numbers or treating them as footnotes comes back to bite, often expensively.

Think about pharmaceutical manufacturing, where a chemical at 98.5% purity instead of 99.9% could mean the difference between an effective medicine and a recall. Even so, raw purity alone doesn’t say everything. Certain heavy metals at single-digit parts per million—lead, mercury, arsenic—turn industrial byproducts into public health nightmares. In my own job experience handling reagents, contamination as minor as unknown organic content in a solvent could foul chromatography columns, throw off analytics, and lead teams astray for days. A food technician once pointed out how a mislabeled batch with “harmless” sulfates triggered widespread allergic reactions. Real harm comes from shortcuts with impurities.

Verifying the product’s purity and adhering to specifications builds trust across the supply chain. Buyers in biotech, food, and tech industries often demand a certificate of analysis with clear batch numbers, testing methods, and quantitative results—not just guesses or averages. In my time sourcing chemicals, I’ve had to reject shipments after just a single failed test, no matter how familiar the supplier felt. Third-party and in-house labs both serve critical roles here. Producers and consumers alike lean on methods like ICP-MS for metals, HPLC for organics, or Karl Fischer titration for water content because shortcuts won’t cut it.

Better communication between manufacturer and user goes a long way. A simple phone call clarifying an ambiguity in a data sheet has often saved big headaches later on. Stronger regulations—not just for the major players but also for smaller suppliers—raise safety standards and offer fair competition. Audits, surprise spot-checks, and transparent recalls don’t just protect end-users; they also build a culture where everyone expects (and delivers) better product. Education on what these spec sheets mean, especially for newcomers, keeps mistakes at bay and raises the bar for everyone in the business.

Without hard standards, chemical purity slips into just another easy promise. Precision, vigilance, and real communication define quality—on the molecular level and in everyday practice.Many of us are no strangers to chemicals in the workplace, lingering on shelves or piling up in storage rooms. Sodium 3-(2-Propyn-1-yloxy)-1-propanesulfonate sticks out because it's used in both research and some specialty manufacturing. Its combination of sulfonate and alkyne groups means it reacts in ways that can surprise anyone expecting a simple salt. That extra reactivity calls for real respect during disposal, not just a quick rinse down the drain.

I’ve worked alongside chemists who figured a water-soluble compound could be washed away without another thought. But this stuff sometimes causes skin and eye irritation, and you really don’t want it settling out in local waterways or showing up at the wastewater plant. Persistent chemicals have a way of sticking around and coming back to haunt communities. Runoff could threaten aquatic ecosystems, so skipping proper disposal cuts corners on real safety.

I admit, safety datasheets sometimes feel like busy-work, but here, the advice is pretty clear: collect any unwanted material in sealed, labeled containers. Wear gloves and goggles, even if you’ve handled “worse.” Ventilation matters, too. I’ve seen cases where skipping these steps meant headaches, rashes, and pointless visits to the doctor. Think of the datasheet as advice from colleagues who learned the hard way.

Never pour leftovers or cleaning rinses down the sink. Designate a clear, tough plastic or glass container (well-marked, tight lid) for collecting any of the chemical, even small spills or cleaning materials like towels. Don’t jam everything in with household trash, since municipal landfills aren’t set up to handle this kind of waste.

From years of working with hazardous stuff, I can say the best approach is to get in touch with qualified chemical waste handlers. Commercial disposal companies handle this compound with established methods: incineration at high temperatures is common, which destroys the chemical instead of spreading it further. Many universities and labs keep lists of trusted waste contractors who stick to local and federal laws, so nobody fiddles around in the gray area between legality and convenience.

It often falls on managers to cut through red tape and get proper disposal programs in place. Set up regular training so all team members learn to spot problem chemicals and follow clear disposal steps. Stock appropriate safety and spill kits. Keep accurate inventories — eliminating “unknown” unlabeled jugs reduces surprises for years down the line.

On the policy end, authorities can support these efforts by giving straightforward guidelines, funding take-back days, and encouraging transparent disposal records. Stronger ties between public utilities, regulators, and the labs or businesses using sodium 3-(2-propyn-1-yloxy)-1-propanesulfonate helps ensure nobody’s left guessing about the right move.

Every time I toss chemical waste in the right bin, I remember seeing the aftermath of careless dumping — sick pets, irritated workers, and complaints from neighbors. Safe disposal of tricky chemicals protects more than just the people handling them. It keeps our water, soil, and communities whole for the long haul.

| Names | |

| Preferred IUPAC name | sodium 3-(prop-2-yn-1-yloxy)propane-1-sulfonate |

| Other names |

PROPYNYL SULFONATE SODIUM SALT 3-Sulfooxy-1-propyl prop-2-ynyl ether sodium salt 3-(2-Propynyloxy)-1-propanesulfonic acid sodium salt Propargyloxypropane sulfonate sodium salt 3-(Prop-2-yn-1-yloxy)propane-1-sulfonic acid sodium salt |

| Pronunciation | /ˈsəʊdiəm θriː ˈtuː ˈprɒpɪn wʌn ˈjɒksi wʌn ˈproʊpeɪnsʌlˌfəʊneɪt/ |

| Identifiers | |

| CAS Number | 473732-97-5 |

| Beilstein Reference | 4711081 |

| ChEBI | CHEBI:131040 |

| ChEMBL | CHEMBL4183598 |

| ChemSpider | 21232742 |

| DrugBank | DB08229 |

| ECHA InfoCard | 03f315a6-2686-4727-a875-e77940f92792 |

| EC Number | 41037-98-5 |

| Gmelin Reference | 1090088 |

| KEGG | C14156 |

| MeSH | Sodium 3-(2-Propyn-1-Yloxy)-1-Propanesulfonate does not have a MeSH (Medical Subject Headings) term. |

| PubChem CID | 11422197 |

| RTECS number | UC8790000 |

| UNII | 33X04XA5QO |

| UN number | UN3077 |

| CompTox Dashboard (EPA) | DTXSID8014702 |

| Properties | |

| Chemical formula | C6H9NaO4S |

| Molar mass | 242.28 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 1.25 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -2.1 |

| Vapor pressure | 0.01 mmHg (20°C) |

| Acidity (pKa) | -2.0 |

| Basicity (pKb) | pKb ≈ 5.2 |

| Magnetic susceptibility (χ) | -62.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.465 |

| Viscosity | 10-30 cP (25°C, 20% in H2O) |

| Dipole moment | 4.29 D |

| Thermochemistry | |

| Std enthalpy of formation (ΔfH⦵298) | -672.8 kJ/mol |

| Pharmacology | |

| ATC code | No ATC code |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P261, P264, P271, P272, P273, P280, P302+P352, P305+P351+P338, P362+P364, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | >100°C |

| LD50 (median dose) | LD50 (median dose): >2000 mg/kg (rat, oral) |

| NIOSH | GV8490000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | Not established |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Sodium 3-mercapto-1-propanesulfonate 3-(2-Propyn-1-yloxy)-1-propanesulfonic acid Sodium 1-propanesulfonate Sodium 2-propyn-1-ylsulfonate |