Before the days of fine-tuned chemical engineering, researchers recognized the potential in basic hydrocarbon sulfonation. Early investigations in the 20th century shaped much of what we see today, as scientists experimented with introducing sulfonic functionalities to aliphatic chains. In the case of propanesulfonic acid, laboratories initially relied on a direct approach, working with propane and aggressive sulfonating agents like oleum. The pathway wasn’t straightforward. Heat handling challenges and mixture control made even simple alkane sulfonation a learning process. The 1950s brought safer, more controlled lab equipment and advances in purification. Chemists grew able to isolate distinct regioisomers, shifting the material from a rare specialty into a known entity. As demand for robust acid catalysts and ionic intermediates grew through the latter half of the 20th century, so did the practical need for functional molecules like propanesulfonic acid. Industrialization spurred refinements, with companies in Japan, the United States, and Germany synthesizing and cataloguing organosulfonic acids for broad commercial deployment.

Propane sulfonic acid sits in a class of small, water-soluble sulfonic acids that handle protons efficiently—key to many synthetic and catalytic needs. Chemists appreciate its clarity: the molecule offers a predictable, manageable acidity and fits easily into both organic and aqueous workflows. Straightforward handling, quick solubility, and low volatility streamline lab operations. Critical to a supply chain, clear nomenclature distinguishes 1-propanesulfonic acid from its structural cousins like 2-propanesulfonic acid or isopropanesulfonic acid, since isomeric arrangement affects physical and chemical utility. Product grades cover both technical and high-purity variants, serving analytical chemistry, battery research, and organic reactions.

A bottle of this acid usually comes as a colorless to faintly pale liquid—sometimes crystalline, depending on purity and ambient humidity. Typical melting points move around 30°C, with boiling usually above 200°C, though decomposition may come first before pure distillation. Strong hydrogen bonding, driven by that sulfonic group, keeps it highly soluble in water. The odor doesn’t grab your nose like acetic or formic acid, which makes it easier to work with in tight laboratory spaces. Strong acidity ranks it well above ordinary carboxylic acids. Dissociation in water compares to well-known sulfonic acids like methanesulfonic and ethanesulfonic acid, with pKa readings often near -2, which means even low concentrations can drive reactions.

Quality control always depends on the intended application. Analytical and battery sectors want 99%+ pure acid, with minimal chloride or metal traces. Producers run batch assays, reporting acid content, color index, and water content, since propanesulfonic acid can absorb moisture from the air. Industrial labeling covers safety controls, batch number, and storage guidelines, plus hazard warnings as required under GHS, REACH, and DOT regulations. Bulk buyers expect their certificates to spell out potassium or sodium residue, sulfur dioxide numbers, and organic impurity screens, especially with any claim about suitability for synthesis or research work.

Classic routes pivot around controlled sulfonation. Chemists choose either direct alkane sulfonation—using fuming sulfuric acid or chlorosulfonic acid as reagents, sometimes catalyzed by trace metals and controlled atmospheres—or they opt for haloalkane precursors in nucleophilic substitution reactions. Direct sulfonation of propane can bring mixtures, so the n-propyl chloride or n-propanol pathways see more use. Reacting these intermediates with sodium sulfite under aqueous or alcoholic conditions, often elevated temperatures, pulls in the sulfonic group, then subsequent acidification with a strong mineral acid like HCl liberates the product. These reactions involve careful rinsing, extraction, and vacuum drying: leftover acids, unreacted starting materials, and partial sulfonates must all get removed for consistent purity.

Precursors like sodium propanesulfonate spring from the same basic chemistry. Propanesulfonic acid itself takes part in esterifications, forming alkyl or aryl sulfonates that serve as hydrotropes and surfactant intermediates. It’s a reliable acid catalyst for dehydration reactions, offering a non-volatile alternative to fuming sulfuric or concentrated hydrochloric acid without the hazards of noxious fumes. In organic synthesis, it helps protonate weak bases, activate alcohols, and mediate condensations. Functionalization of the hydrocarbon tail allows attachment to polymers or surface modification, so advanced research often looks to graft propanesulfonic acid groups onto supports like silica or polystyrene, creating robust ion-exchange resins and catalysts.

Nobody likes walking into a chemical warehouse and finding a dozen similar names for the same substance. Propanesulfonic acid’s aliases include 1-propanesulfonic acid, n-propanesulfonic acid, and straight-propanesulfonic acid. The sodium, potassium, and ammonium salts—sold as sodium propanesulfonate and so on—highlight the adaptability of the molecule in broader chemical work. International catalogues and safety data sheets stick closely to the IUPAC identifiers, so cross-referencing by CAS number matters for import-export and large-scale orders.

Working with concentrated acids demands vigilance, and propanesulfonic acid is no exception. Direct skin contact brings immediate irritation, redness, even burns at higher concentrations. Lab staff gear up with gloves, goggles, and face shields. If a bottle breaks, the acid’s water solubility means it spreads fast, so quick dilution and neutralization with sodium bicarbonate prevent long-term surface damage. Inhalation isn’t common thanks to low volatility, but acid mist can form during vigorous reactions or accidental spills, irritating the respiratory tract. Storage leans toward sealed, airtight containers with desiccation, kept clear of oxidizers and strong bases. Waste disposal relies on neutralization before drain disposal—strict in industrial settings and heavily regulated in environmental permits. Companies publishing their safety records and incident rates help build trust and accountability, meeting updated regional safety standards and labor regulations.

Wherever you need a strong, non-smoke-forming acid, propanesulfonic fits the bill. The electronics and battery sectors use it for pH adjustment, electrolyte solutions, and as a proton source in specialty membrane systems. In pharmaceutical labs, it provides acidification without bringing the corrosive risk or atmospheric hazards tied to concentrated mineral acids. Water treatment specialists occasionally choose its salts for gentle descaling and ion exchange, especially in sensitive setups. Material scientists graft its backbone onto polymers or surfaces as a stepping stone to next-generation catalysts, membranes, and selective sorbents. Synthetic chemists lean on it as a supporting acid for dehydration, esterification, and condensation reactions that can’t tolerate the clutter of sulfate or chloride byproducts. Even analytical labs use propanesulfonic acid as a calibration acid, leveraging its known dissociation and handling traits in titrations or as a standard solution.

Researchers hunt for greener sulfonation methods with less aggressive conditions and better atom economy. Electrosynthetic approaches, which use controlled electrical current to drive sulfonic group installation, deliver hope for energy savings and less chemical waste. Chemists also chase new derivatives, adding bulk to the hydrocarbon tail or tethering the sulfonic group to heterocycles, chasing improved performance in ion-exchange columns or as phase-transfer catalysts. Material science projects cross the acid with silanes or resins, taking advantage of solid supports for easier recycling and lower process costs. Better purification methods push product quality upward, with chromatographic and crystallization techniques borrowed from pharmaceutical work showing real promise for research-grade acid.

Animal studies and environmental reports show moderate acute toxicity: exposure above threshold leads to irritation, but propanesulfonic acid doesn’t throw off the chronic, cumulative toxicity seen with certain aromatic or long-chain sulfonic acids. In water, it breaks down faster and absorbs more easily onto soils. Regulatory bodies—EPA, ECHA, and equivalent agencies—track emission and tell manufacturers to maintain low exposure levels. Lab and plant records point to rare severe incidents, provided personnel respect handling guidelines and follow spill-response protocols. Chronic exposure data remain limited, but risk profile stays well below that of more persistent organosulfonic analogues such as toluenesulfonic acid.

The demand for strong, water-soluble acids that won’t vaporize or oxidize surfaces remains steady in tech and synthesis sectors. As battery research accelerates, safer, less corrosive electrolytes attract industry attention, expanding the role of propanesulfonic acid and its salts. Better methods for attaching the sulfonic acid group to high-surface-area supports unlock new catalysts, especially as green chemistry and recyclable materials take priority. On the research side, expect work to focus on selective synthesis, milder reaction protocols, and hybrid molecules with tunable acidity for advanced membrane and sensor systems. Regulatory studies will expand, prompted by tighter environmental standards and ongoing toxicity reviews. As the push for safer, more effective acids continues, propanesulfonic acid looks set to maintain and even expand its footprint in specialty chemicals, research labs, and industrial processes alike.

Propanesulfonic acid often sits quietly in the background, but it carries a reputation among chemists for a reason. Sometimes called 1-propanesulfonic acid, this compound proves its worth in laboratories and manufacturing plants day in and day out. I’ve watched projects stall for weeks until someone suggested using it as a catalyst—the boost noticeably completed reactions faster and with better results.

Many professionals lean on propanesulfonic acid to push chemical reactions along. In organic chemistry, it acts as a strong acid, yet it behaves in a way that lessens unwanted side reactions. Supporting the transformation of raw materials into refined products, it streamlines workflows in pharmaceuticals, agrochemicals, and advanced materials. For instance, researchers often choose it over sulfuric acid because it causes fewer headaches during purification. Its effectiveness shows up especially in synthesis steps needing a reliable, non-volatile acid to ensure the process stays on track.

Most of the time, companies building new molecules face many hurdles. Using an acid that won’t easily evaporate or corrode equipment matters when you’re running large batches. Propanesulfonic acid, with its easy handling and strong acidity, gets poured into reactors to produce specialty chemicals with fewer safety worries.

Nobody wants to lose ground in the race for better batteries. Scientists working on fuel cells and energy storage technologies spotted propanesulfonic acid as a chemical that might solve stability issues. By adding it to membranes in fuel cells, teams have managed to improve ion movement, which means more reliable electricity output. The acid’s simple molecular structure fits nicely in polymer systems, avoiding the need for expensive additives.

Environmental regulations keep tightening, forcing every manufacturer to rethink their choice of process chemicals. The threat of toxic byproducts looms over many industrial acids, but propanesulfonic acid earns points for breaking down more cleanly in wastewater treatment. Its straightforward decomposition cuts back on environmental risk and disposal costs. Companies aiming to hit green targets turn to it to achieve cleaner operations and better compliance with safety rules.

Although propanesulfonic acid already holds a spot in many labs, new uses keep emerging as industries chase greater efficiency. In polymer chemistry, it acts as a trusty monomer building block for high-performance resins. Its mild yet effective properties also attract researchers searching for sustainable alternatives to legacy acids. If cost drops with wider use, and suppliers keep quality consistent, more companies could swap out older, more hazardous acids for it.

Much of the trust in propanesulfonic acid comes from repeat successes. It simplifies steps in chemical synthesis, speeds up innovative research in the energy sector, and fits environmental standards without extra complications. From my own experience, projects that once burned through mountains of paperwork and safety checks run smoother with this acid because it’s dependable and easy to work with. For those taking chemical processes seriously, propanesulfonic acid deserves a spot in the toolkit.

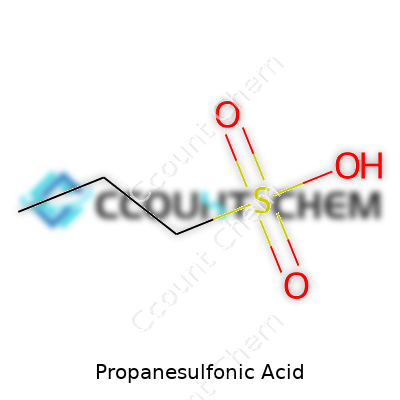

Propane has three carbon atoms. When you attach a sulfonic acid group to it, you get something called propanesulfonic acid. Chemically, it's written as C3H8O3S. Its structure looks like this: a propane chain with a –SO3H group hanging off one end. Chemists won't miss this one; the extra acid group brings special properties.

In labs, propanesulfonic acid works as a strong acid and a great ion-exchanger. This comes in handy for catalysis and organic synthesis. I remember talking with an industrial chemist last fall who described using this acid when working on high-value pharmaceuticals—they needed something stronger than acetic acid, and this fit the bill. The sulfonic acid group brings water solubility, so the substance dissolves without fuss. That helps during reactions where surface contact matters.

It doesn't stop at the lab. This acid can play a part in the textile industry if folks want to adjust pH quickly or in electroplating shops that need consistent acid strength to keep metal surfaces bright. The chemical acts as a kind of workhorse compared with weaker acids. Reliable, predictable—and that counts for a lot when scaling up production.

The formula—C3H8O3S—isn't just academic. Getting the count of atoms right means you can predict the molecule's behavior. Think about storage and safety. Too much acid leaking or spilling? You want to know what's in your barrel. With propanesulfonic acid, the structure tells us it’s dense, it can bite through some organics, but it’s less volatile than mineral acids like hydrochloric. This is important for anyone down the supply chain, from shippers to technicians who have to handle the stuff day to day.

Nothing beats knowing your chemicals before you bring them into your workplace. Propanesulfonic acid can irritate skin and eyes. Anyone working with it should wear gloves and goggles—nobody likes a surprise trip to the safety shower. I’ve seen spills managed smoothly in prepared labs with proper containment and neutralization procedures using sodium bicarbonate. If you pour it down the drain, it can lower wastewater pH, so folks in charge of compliance need protocols for neutralization before disposal.

Most cities require disclosures for acids in bulk. MSDS sheets point out that chronic exposure is not well-documented. To stay ahead, companies should put in spill kits, train staff regularly, and double-check ventilation in storage areas.

Folks looking for greener chemistry focus on reducing persistent chemicals and exploring safer acids, but propanesulfonic acid’s combination of strength, solubility, and relative stability still secures its spot in chemical toolkits. Cleaner alternatives work for some tasks, but not all. The goal: minimize risks, train well, and understand exactly what’s in play—right down to the last atom.

Propanesulfonic acid doesn’t show up in the everyday world for most people. You’ll spot it more in chemical labs and some industrial settings. It’s a strong acid with a sharp bite, something production chemists know well from personal experience. Spilling even a tiny amount on a bench leaves marks that don’t wipe off easily. Most folks who have handled chemicals get the message quickly: wear gloves, goggles, and make sure your ventilation works.

It won’t take long to feel the impact if skin or eyes make contact. Propanesulfonic acid burns and irritates on contact, similar to sulfuric acid in how it reacts with biological tissue. Eyes can take only a brief exposure before pain and potential damage kicks in. Burning and redness develop fast. Inhaling its vapor, while not as aggressive as some volatile organic compounds, still irritates airways and nose. Anyone with asthma or respiratory concerns faces greater risk, since strong acids can aggravate those issues. In medical literature, acids of this type earn a reputation as occupational hazards -- not household ones.

The real worry with chemicals often lies not just with one-time accidents, but what happens over decades. Propanesulfonic acid, like most strong acids, doesn’t show up much in chronic exposure data, probably because careful handling reduces most long-term risks. Workers in chemical factories use closed systems and protective gear for good reason. Prolonged skin contact may eventually lead to dermatitis or chemical burns. Nobody wants a workplace injury from routine carelessness. Respiratory exposure on a regular basis can worsen lung health, but strict regulation and airing out workspaces keep incidents low.

Acids can bring trouble once they escape the lab or plant. Propanesulfonic acid, released in quantity, will contaminate water, soil, and threaten local aquatic life. Fish and small organisms usually take the first hit, especially in streams with little buffering capacity against added acidity. In the real world, environmental releases almost always trace back to accidental spills or illegal dumping. Good companies invest in spill containment, neutralization procedures, and mandatory training. Often, they team up with local authorities to plan for possible leaks. The lesson is clear: prevention works better than cleanup after contamination hits.

Safety doesn’t rest on a single solution. It builds on multiple layers of protection. Chemical-resistant gloves, sturdy eyewear, and reliable ventilation offer the first line of defense. Training matters almost as much as equipment. I’ve often seen new lab workers focus on splash goggles, but overlook proper storage and acid labeling. Emergency eyewash stations and neutralizing agents, kept nearby, can save eyesight and reduce injuries if spills happen. Regular audits and honest reviews of procedures help catch lazy habits before they become accidents.

Many chemicals present some danger. Propanesulfonic acid won’t win any prizes as the most hazardous, but ignoring its risks would show inexperience. Chemical safety rules exist for a reason—personal health and environmental protection ride on those guardrails. Regulatory agencies, including OSHA and the EPA, track and manage these substances closely. Respect for these standards, not shortcuts, keeps people and communities safer.

Propanesulfonic acid drew a lot of attention in my chemical engineering days, not just because of its strong acidity, but also due to stories about lab mishaps from poorly sealed bottles. On paper, its formula — C3H8O3S — hides its intensity. Up close, it smells sharp, acts corrosive, and can cause more than just a ruined pair of gloves. After seeing a benchtop corrode because someone left a cap loose, I never took basic storage for granted again.

Safety starts with understanding the real risks. Propanesulfonic acid will burn skin, damage eyes, and corrode soft metals. Breathing its fumes leads to a hacking cough and inflamed airways. If it spills, it’ll eat through floor coatings and can soak into soil, making cleanup expensive. The EPA has pretty strict guidelines for storing strong acids, and I’ve seen even savvy lab managers get into hot water over minor spills because they kept their acids near heat sources or strong bases. Mixing up acids and bases gets dramatic in real life, not just in chemistry textbooks.

A good storage spot for propanesulfonic acid stays away from sunlight, heat, and direct drafts. Heat speeds up reactions and can cause the bottle to pressurize or the acid to degrade. In basement storerooms, darkness and coolness help, but humidity can creep in, and strong acids pull in moisture from the air. That makes tight sealing a top priority. I remember storing acids in polyolefin bins on lower shelves—never above shoulder height—because spilled acid travels down, not up. High shelves spell trouble in an emergency, especially if you have to deal with trembling hands or splashed goggles.

Glass used to play a starring role in chemical storage. These days, high-density polyethylene (HDPE) and similar plastics stand up better, especially with corrosive acids. Metals corrode and break down, and those pretty clear bottles sometimes trick folks into underestimating what’s inside. I've seen entire cabinets cleaned out when one leaky cap attacked a metal shelf. Labeling every bottle — with the date received and clear hazard icons — stays non-negotiable. Quick access to emergency eyewash and spill kits means any mistake doesn't turn into a disaster.

Never stash propanesulfonic acid near bases, organic solvents, or oxidizers. I once saw an entire prep bench evacuated because an intern shelved it next to ammonia solutions. Strong acids and bases reach for each other like magnets, and their reaction makes clouds of corrosive gas. Segregation cabinets matter because even a cracked cap can create dangerous fumes. Pouring acids in a fume hood and keeping incompatible substances locked away reduces panic and emergency room visits.

Learning from mistakes, I always check for leaks, crystals, or strange smells before using any stored acid. PPE is a must—gloves, goggles, and lab coats. If a spill happens, neutralize it with sodium bicarbonate or a verified acid neutralizer, not water. Water can splash, spreading the acid. Good records track usage, and regular checks spot problems before they grow. Trust in people following standard procedures matters as much as trust in equipment. In my experience, setting up a culture of open reporting caught issues early and stopped worrying in its tracks.

Storing propanesulfonic acid doesn’t call for complicated technology, but it does mean following everyday wisdom. Good habits keep people and property safe. Early in my lab career, I learned to respect strong acids, not just because of what could go wrong, but because so much can go right with solid planning and clear routines.

Step into any chemical plant focused on producing specialty chemicals, and you’re likely to hear about propane sulfonic acid. This sulfonic acid packs a punch as a cation exchange resin. With a strong acid group built into its structure, it replaces mineral acids in refining and purification. For those who handle pharmaceutical intermediates, using it helps cut down on harsh side reactions that can ruin a batch. That not only means fewer headaches from impurities but also real savings on cleanup and disposal.

In the resin business, propane sulfonic acid helps bind or swap ions fast and predictably. That matters if you want high-purity products or if a process needs a repeatable result every day. Many water treatment facilities now reach for it instead of sulfuric acid, cutting down on damaging byproducts and maintenance calls.

Many of us in the lab know propane sulfonic acid for what it does as a catalyst. Pharmaceutical teams rely on its strength to help craft complex molecules, especially in reactions where other acids stall out or drive up the costs. Catalysts using this acid often help produce flavors, fragrances, and key drug ingredients in shorter runs with better yields.

It’s not just about speed. Propane sulfonic acid is easy to handle and dissolves cleanly in polar solvents, which means fewer clogged pipelines and more control for engineers running large batches. This predictability is a quiet hero behind many breakthroughs in organic chemistry.

Metal finishers have a soft spot for acids that do the job without making life harder. In electroplating, propane sulfonic acid helps form stable metal deposits and tends to be much less corrosive to equipment than others, like hydrochloric acid. Platers notice brighter finishes and fewer defects. The difference shows up on everything from printed circuit boards to automotive parts.

I’ve seen metal shops recover from downtime and long maintenance cycles after swapping out traditional acids for propane sulfonic acid. Workers report fewer fumes and splashes, which helps keep the focus on output and less on hazard suits.

As battery tech keeps moving forward, the acids running inside batteries get more attention. Propane sulfonic acid is showing up more often inside new flow batteries and specialty supercapacitors. The acid’s stability under electrical stress keeps energy storage consistent and reliable, especially where reliability means the difference between a device working or failing in the field.

Factories can run longer cycles between breakdowns, and the acid tends to generate fewer harmful byproducts, helping companies meet tougher environmental standards. Storage and recycling also get a bit easier, since propane sulfonic acid doesn’t bring along some of the more volatile side effects of mineral acids.

If I’ve learned anything working with industrial chemists and engineers, it’s that the right tool at the right time makes all the difference. Propane sulfonic acid stands out for its reliability and safety compared to older acids. By cutting down on unwanted reactions and reducing maintenance headaches, it helps people focus on the work that really matters. With pressure growing to make manufacturing safer and cleaner, I’d bet on propane sulfonic acid to keep playing a bigger role in processes from pharmaceuticals to energy.

| Names | |

| Preferred IUPAC name | propanesulfonic acid |

| Other names |

1-Propanesulfonic acid PSA Propylsulfonic acid |

| Pronunciation | /prəˌpeɪnˈsʌlfɒnɪk ˈæsɪd/ |

| Identifiers | |

| CAS Number | 1112-81-0 |

| Beilstein Reference | 3580527 |

| ChEBI | CHEBI:50672 |

| ChEMBL | CHEMBL1377 |

| ChemSpider | 73914 |

| DrugBank | DB01819 |

| ECHA InfoCard | 100.010.320 |

| EC Number | 211-548-4 |

| Gmelin Reference | 82298 |

| KEGG | C01491 |

| MeSH | D011375 |

| PubChem CID | 7332 |

| RTECS number | TY9650000 |

| UNII | LU74E41JD5 |

| UN number | 2495 |

| CompTox Dashboard (EPA) | DTXSID7032992 |

| Properties | |

| Chemical formula | C3H8O3S |

| Molar mass | 124.18 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.289 g/cm³ |

| Solubility in water | Very soluble |

| log P | -1.3 |

| Vapor pressure | 0.0025 mmHg (25°C) |

| Acidity (pKa) | -2.0 |

| Basicity (pKb) | 1.63 |

| Magnetic susceptibility (χ) | -4.9e-6 |

| Refractive index (nD) | 1.417 |

| Viscosity | 15 mPa·s (25 °C) |

| Dipole moment | 3.22 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 132.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -587.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1491 kJ/mol |

| Pharmacology | |

| ATC code | C09XA21 |

| Hazards | |

| Main hazards | Causes severe skin burns and eye damage. |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS05 |

| Signal word | Danger |

| Hazard statements | H290, H314 |

| Precautionary statements | P260, P264, P280, P301+P330+P331, P303+P361+P353, P304+P340, P305+P351+P338, P310, P321, P363, P405, P501 |

| NFPA 704 (fire diamond) | 2-0-2-Acido |

| Flash point | 138°C |

| Autoignition temperature | 420 °C |

| Lethal dose or concentration | LD50 (oral, rat): 970 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 600 mg/kg |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Propanesulfonic Acid: Not established |

| REL (Recommended) | 2-Propane sulfonic acid |

| IDLH (Immediate danger) | IDLH: 250 ppm |

| Related compounds | |

| Related compounds |

Methanesulfonic acid Ethanesulfonic acid Benzenesulfonic acid Toluene-4-sulfonic acid Propanesulfonate Sulfonic acid |