Octane-1-sulfonic acid sodium salt came about in response to a growing need for specialized reagents as chemistry moved past the basics in the late twentieth century. Researchers needed to separate compounds more efficiently, especially surfactants and organics that didn’t play well with traditional methods. The introduction of sulfonic acid derivatives gave separation science a boost. Sodium salts of these acids helped scientists push chromatography and analysis into new territory. I’ve seen stories from chromatographers who finally separated tough samples thanks to a well-prepared batch of this reagent. Over decades, its manufacture shifted out of hand-mixed flasks into processes defined by hard-won experience, driven by research labs asking for purer, more consistent batches, and pharmaceutical manufacturers seeking tools they could trust.

Octane-1-sulfonic acid sodium salt, or sodium 1-octanesulfonate, appears as a white to off-white powder—surprisingly bland for a chemical with such a punch in analytical work. Its alkyl chain, eight carbon atoms long, makes it just hydrophobic enough to interact with many organic molecules but keeps it water soluble because of the sulfonic acid group. Its main role pops up in reversed-phase ion-pair chromatography, where it acts as a mobile phase additive to help separate molecules that would otherwise run together. Its influence extends to pharmaceuticals, environmental science, and petrochemical testing. Sometimes it’s about releasing hidden details from a sample; other times, it’s about chasing contaminants that refuse to show themselves using less clever tools.

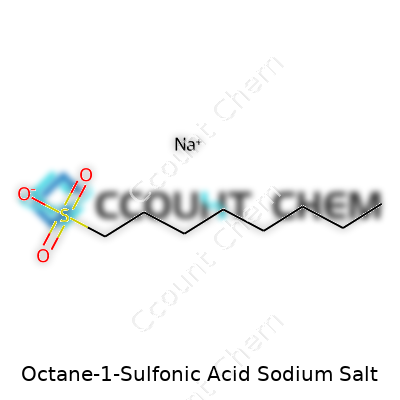

This salt offers a unique mix of moderate molecular weight, solid-state stability, and decent water solubility. Melting at temperatures just over 300°C, it withstands most storage temperatures without caking or breaking down. Its formula, C8H17NaO3S, shows an eight-carbon chain carrying a sulfonic acid group at one end, neutralized by sodium. This structure strikes a balance in hydrophilic-hydrophobic interactions. Such a balance makes sense when I think back to tough separations in college chemistry labs; getting the right salt in the right place spelled the difference between tangled data and clear answers. It stands up to air and moderate heating and shrugs off mild acids or bases, though it doesn’t take kindly to extreme conditions. Researchers appreciate its ability to dissolve in water without excessive foaming or sticky residues, raising accuracy and reproducibility.

Manufacturers package sodium 1-octanesulfonate in high-density polyethylene bottles or lined drums to prevent moisture uptake. On the technical paperwork, you notice the word “assay” every time—the target purity usually sits above 99%. Moisture content sits tightly controlled, and chloride, sulfate, and heavy metal impurities stay below detection limits. These specs come from customer demand. Any error here can send thousands of chromatograms sideways. Each label needs to show batch number, manufacture date, intended use, handling precautions, and storage advice—details more than a formality, since labs rely on this chain of data for confidence in each run. Technical datasheets sum up regulatory compliance (like REACH or U.S. import rules), giving buyers more to go on when choosing a supplier. I learned quickly that confusing or missing specs cause headaches in the lab.

Making sodium 1-octanesulfonate isn’t magic. Production typically starts with octanol or octene. Chemists react these with sulfur trioxide or oleum, leading to sulfonation. The resulting sulfonic acid then meets caustic soda (sodium hydroxide) to yield the sodium salt. Purification happens next—crystallization, filtration, and careful washing remove undesirables. Each step matters: get lazy with sulfonation, and impurities sneak in; rush the washing, and sodium hydroxide leaves behind a stubborn alkaline bite that spoils the product. The manufacturing process weaves together safety, quality control, and decades of learned habits in a dance that really shows just how complex “routine” chemicals can become.

In the lab, octane-1-sulfonic acid sodium salt often plays supporting roles—as an ion-pairing agent more than an active reactant. It slips into water and helps organize complex molecules for better separation and analysis. Under strong acid, the sodium can be swapped out to regenerate the acid, or the sulfonic group can be leveraged in coupling reactions. Every so often, researchers tweak the alkyl chain to push the molecule’s lipophilicity up or down by a carbon or two, developing new salts to chase trickier analytes. Sulfonates sometimes show up as starting points for surfactant synthesis or as building blocks in specialty detergents, reminding us that even tightly defined chemicals can end up in unexpected places.

Over the years, the industry threw different names at this compound—sodium n-octanesulfonate, 1-octanesulfonic acid sodium salt, and in pharmaceuticals, sometimes just “sodium octyl sulfonate.” You spot these labels in method protocols, warehouse receipts, and academic journals. None have turned into household names, but those in analytical chemistry know them by code numbers and supplier abbreviations. Some companies branded their own lines with tweaks for regulatory or purity standards, but the chemistry stays true to the original.

Those who’ve handled the salt appreciate its relatively low hazard profile. With basic precautions—gloves, goggles, good lab ventilation—it remains manageable. Skin and respiratory irritation can happen, and direct ingestion or eye exposure calls for medical advice. Dust suppression means avoiding unnecessary powder handling. Disposal demands compliance with both in-house protocols and local regulations; most facilities forward spent material for controlled incineration. Safety data sheets, updated with changing regulations, help users stay ahead. Regulatory standards from the European Chemicals Agency and OSHA guide supplier statements and in-house practices. The best labs train regularly, refresh safety signs, and take exposure prevention seriously; careless habits don’t belong when any fine powder floats through the air.

This compound wins most of its praise in analytical chemistry, especially in high-performance liquid chromatography. Its job revolves around pairing with analyte molecules to tweak retention times, letting operators tease complex mixtures apart with precision. Pharmaceutical quality control leans heavily on this reagent for separating active ingredients from impurities, degradation products, and counter-ions. Environmental labs use it parsing pesticide traces or tracking groundwater contamination. Industrial monitors draw on its separation power for process analyses, measuring purity or checking compliance. In electrophoresis, it stabilizes certain buffer systems, giving sharper results. Each use builds on a mix of experience, method validation, and sometimes a streak of problem-solving when alternatives stumble.

In R&D, sodium 1-octanesulfonate pulls double duty—serving as a method benchmark and a pivot point for new reagent design. Method developers lean on it to establish baselines, then try tweaks: a longer or shorter alkyl chain, another counterion, a new solvent system. Publications outline its effect on resolution, peak shape, and analyte response, helping researchers compare options under real-world sample loads. Instrumentation manufacturers sometimes work with suppliers to guarantee reagent quality, since any drift affects instrument performance. Research grants point toward the paired need for sensitivity and selectivity, often with this salt as a measure of progress or a starting block for new separation strategies.

Medical and environmental researchers dug into toxicity early, given its use in water-based systems and analytical runs touching pharmaceuticals. Data to date show low mortality in animal studies—the salt clears the body without strange accumulation, and breakdown products mostly match those from related surfactants. Still, chronic exposure to high amounts isn’t fully explored. Regulatory screening watches for skin, eye, and respiratory irritation. As labs crunch through more and more samples, do we really know what unlimited, long-term exposure means? Experience says regular checks and rigorous containment guard against surprises. Facilities draft policies built on pragmatic risk evaluation, ensuring nobody shrugs off the possibility of subtle effects or underestimates environmental persistence.

Looking out, demand for high-purity sodium 1-octanesulfonate will keep rising as analytical methods grow more refined. Next-gen pharmaceuticals and tighter water quality rules mean researchers need separation tools they can count on for lower detection limits and repeatable results every time. Synthetic chemists are already asking for customized alkyl chain lengths or alternative counterions tuned to emerging needs. Environmental labs want formulations that break down more easily, marrying analytical power with sustainability. Vendors will step up with greener production methods, faster shipping, and digital traceability woven into supply chain management. Analytical chemistry owes a quiet debt to compounds like this—a reminder that progress hinges on trusted ingredients and the people who battle every day for clarity, not just in the results but in the methods that get us there.

If you’ve ever been around a laboratory focused on chemistry or pharmaceuticals, you might have spotted a bottle labeled “Octane-1-Sulfonic Acid Sodium Salt.” To a lot of folks, the name sounds like gibberish. For those who run high-pressure liquid chromatography (HPLC) instruments, the stuff is a real workhorse. HPLC separates mixtures and identifies their components—even in stuff as complicated as medicine or environmental samples. The sodium salt form of octane-1-sulfonic acid acts as an ion-pairing reagent. It binds with molecules that usually sneak through undetected, helping keep the peaks separate and easy to read on a chromatogram.

There’s not a lot of glamour in lab work. No one shakes hands with a chemical reagent at a conference. But accuracy and repeatability matter in science. Sure, computers run the tests and robot arms pipette solutions, but a clean, sharp separation hinges on getting the chemistry right. Octane-1-sulfonic acid sodium salt delivers here. It locks onto polar and charged compounds, pulling them out from a messy soup so scientists can spot what they need. Quality control in pharmaceuticals, doping control in sports, environmental monitoring—without solid chromatography, these fields turn murky.

Quality in the labs depends on reagents that do their jobs without introducing surprises. Impurities in your ion-pairing agent throw off measurements. End up with unreliable results and the consequences add up fast—think misidentified drug dosages or missing out on contaminants in water. Traceability and consistency, backed by transparent manufacturing, play a big role in both trust and safety. Several suppliers provide certificates of analysis that help labs trace the material back to its source. I remember spending hours validating new lots of this salt in a contract lab. Any blip meant extra troubleshooting or rerunning stacks of expensive samples.

Over time, shifting to higher-grade reagents kept us on the right side of auditors and regulators. This kind of attention keeps public health protected, since labs around the world check food, drugs, and environmental samples using these same tested protocols. By sticking to proven materials, fewer mistakes creep into the data, and recalls or missed warnings fall.

A reagent like octane-1-sulfonic acid sodium salt seems mundane. Too easy to overlook compared to the equipment that grabs headlines. Yet, every working chemist knows that productivity in the lab depends on steady supply. Shortages in 2020 threw off a lot of projects. Teams scrambled to find alternatives, which meant rechecking method validation and sometimes accepting less reliable results. Maintaining a reliable pipeline of reagents is not just smart planning—it keeps labs from skidding to a costly halt.

Solutions here start with better communication between suppliers and lab managers. Sharing data about inventory levels, expiration dates, and alternative sources keeps science running smoothly. Training staff to check reagent quality as part of routine lab maintenance also heads off bigger problems. Problems multiply when corners get cut—so the best labs build quality checks right into their workflow.

Octane-1-sulfonic acid sodium salt isn’t about to become a household name. Even so, its small role in the giant process of chemical analysis makes a big impact on data integrity and public trust. Customers—from pharmaceutical companies to water-testing agencies—depend on it to do its job every day. That steady, dependable performance lets scientists focus on their real work: uncovering answers and protecting health.

Most folks working in analytical chemistry spend plenty of time with various chemicals meant to simplify or speed up separation methods. Among these compounds, Octane-1-sulfonic acid sodium salt stands out—not because it sounds complicated, but because it solves real problems in separating different substances. Its chemical formula, C8H17SO3Na, seems straightforward at a glance, yet it packs a punch in real-world applications, especially when used as an ion-pairing reagent in high-pressure liquid chromatography (HPLC).

Breaking down C8H17SO3Na gives a clear picture of what’s happening on a molecular level. The “octane” part tells us the compound has eight carbon atoms forming a straight chain, like in regular n-octane. The “sulfonic acid” section means there’s a sulfonate group—SO3—attached to one end of this chain. When sodium swaps in for a hydrogen on the sulfonic acid group, it becomes the sodium salt form (Na). Each piece of this structure brings its own usefulness in the lab.

Researchers trust this compound for its consistency. The long carbon tail gives a strong hydrophobic character, while the charged sulfonate group stays soluble in water. In practical terms, C8H17SO3Na acts as a bridge between water-loving and fat-loving substances, helping complex mixtures separate smoothly in HPLC. Labs run into all sorts of sticky situations with polar and non-polar molecules mixing together, and a reagent like this helps cut through the mess.

Trust matters in science, both in the people and in the chemicals they use. A well-defined formula like C8H17SO3Na lets researchers know exactly what they’re working with, reducing surprises and setbacks. Reliable results depend on predictable reactions, and there’s value in double-checking the chemical formula and structure before any experiment kicks off. The chemical structure of octane-1-sulfonic acid sodium salt proves its worth again and again, delivering repeatable results.

Over the years, I have relied on ion-pairing agents to boost the results from tricky residue analyses in environmental samples. Without sulfonate salts doing their job, some tests might take two or three attempts just to get decent separation. It saves time, money, and headaches, all by understanding how that formula fits into the workflow.

Not every solution in chemistry needs to be flashy or expensive. Sometimes, the answer is a clear understanding of a compound’s formula and what it brings to the table. Octane-1-sulfonic acid sodium salt solves persistent problems by offering hydrophobic and hydrophilic balance, all wrapped up in a molecule with a clear formula. Its applications touch medicine, environmental analysis, and pharmaceuticals. That single detail—a clean chemical formula—lets every researcher know they can depend on it, tweak their separation methods, and chase after results that matter for health, safety, and progress.

By recognizing compounds like C8H17SO3Na for their practical advantages and making sure the formula is ready at hand, science keeps moving forward.

Octane-1-sulfonic acid sodium salt is a chemical a lot of us never hear about unless we work in labs—especially those focused on chromatography. You find it in mobile phases that help scientists separate substances for better analysis. This salt lets chemists see what’s inside tricky samples, and it’s earned a quiet reputation as a reliable helper behind the scenes. Still, as with a lot of chemicals, safety always comes first. People sometimes ask if it’s dangerous or toxic, and this is more than just a practical question. Safe handling and transparency help both workers and the public.

From my years working with researchers and industry folks, I can tell you direct exposure to this compound in pure form won’t do anyone any favors. Skin irritation can pop up after contact, and eyes react even to small splashes. Inhaling dust or fine powder can irritate the respiratory tract. Swallowing it isn’t wise either—a sore throat, an upset stomach or worse could follow. Personal experience with spilled chemicals has made me careful even with compounds marked “low hazard.”

Most chemical distributors attach labels carrying GHS hazard statements—these spell out hazards like "may cause irritation." Compared to true nasties like concentrated acids, this sodium salt sits lower on the risk ladder, but it’s no table salt. Its structure means it won’t burn your skin on contact, though it still deserves gloves, goggles, and a well-ventilated bench. Data sheets support this: the oral toxicity studies on rodents set LD50 well above 1800 mg/kg, which tells us it takes a fair bit to cause major harm in a one-off accident. Still, high doses can bring problems, and you can’t always guess who’s sensitive.

Run-off or dumping calls for extra care. Sulfonic acids and related salts can pose trouble for aquatic environments if spills happen in large quantities. Fish, algae, and insects all hide in these ecosystems, and chemicals upset this delicate balance. Local wastewater systems aren’t built to scrub out every industrial molecule, and environmental incidents often echo beyond the lab. That’s why proper use, storage, and disposal matter.

Having watched chemical shipments roll into research centers for years, I’ve seen that accidents usually happen when someone either rushes or thinks the rules don’t apply to “less toxic” substances. A sloppy attitude breeds trouble. Even substances that seem routine can stack up over time or react with others to form new hazards. Sometimes disaster doesn’t come in a flash—damage unfolds drip by drip.

The staff working with octane-1-sulfonic acid sodium salt know the drill: PPE, labels, clear air, locked storage. Good ventilation keeps powders from riding the air into someone’s lungs. Staff need ongoing training so they spot risks before they escalate. Chemical hygiene plans matter as much as the science itself. It’s always better to sweep up a tiny spill now than face a big problem later.

For the wider public, transparency and information sharing should be at the center. Companies owe it to their neighbors and customers to publish safety sheets, handle chemicals as if families lived next door, and train every worker, not just the folks in white coats. People trust companies that treat safety as an everyday habit, and that trust sticks longer than any brand promise.

Rotating safety checks, clear labeling, quick cleanup kits—these small choices go miles. Scientists and staff get the right gear, and local water systems avoid another contaminant. Industry bodies can share the lessons, swapping stories about near-misses so others don’t repeat them. It just comes down to keeping eyes open, hands safe, and communication honest.

Many lab chemicals demand respect, but some push boundaries a bit more than others. Octane-1-sulfonic acid sodium salt belongs to a group of chemicals that won’t hesitate to show their temper if handled wrong. Anyone working with chemistry learns early on that safe storage isn’t just about keeping tidy shelves—it’s about keeping people healthy and property safe.

Octane-1-sulfonic acid sodium salt serves as a popular ion-pairing agent in high-performance liquid chromatography (HPLC). Its water solubility and ionic character make it valuable but also sensitive to certain environmental triggers. Mishandling or poor storage can reduce its shelf life and even produce hazardous situations. I can recall more than one instance where a mislabeled container or poor sealing led to wasted material and unnecessary risk, sometimes setting back entire experiments.

Moisture control ranks high on the list of priorities. This compound pulls in water from its surroundings, thanks to its hygroscopic nature, so a leaky lid or careless storage spot can ruin the whole batch. Even if it looks fine to the naked eye, moisture can sneak in and start to degrade the substance, influencing the integrity and accuracy of lab results. I’ve seen costly repeat analyses result from cutting corners on storage basics.

Air-tight, non-reactive containers made from glass or specific plastics form the first line of defense. Avoid metal containers, as some metals react with sulfonic acids over time. The label should always stand out and include the preparation date, so no one has to guess if the material is still good for use.

Store the material away from heat sources and direct sunlight. Elevated temperatures induce decomposition or side reactions, and sun exposure can tip off slow chemical changes no one wants happening. An indoor, ambient room—preferably with climate control—proves most reliable. Fluctuating temperature or busy bench tops invite instability, especially for chemicals that participate in sensitive analyses like HPLC.

Stash away Octane-1-sulfonic acid sodium salt from incompatible substances. Strong acids, bases, and oxidizing agents top the list of no-go neighbors. A small spill from a nearby shelf can prompt unexpected reactions. Clear shelves, labeled sections, and careful inventory keep disaster at bay. Years in university labs taught me how easily one errant bottle toppling over can cause panic—and unnecessary cleanups.

Comprehensive staff training helps enforce storage guidelines. Folks sweeping in from home or changing jobs often bring habits from past workplaces, not all of them safe. Clear signage, routine safety audits, and straightforward checklists bridge the experience gap and set a good example for newcomers.

Routine checks on containers, labeling, and storage temperature catch problems early. Even the most careful worker can miss a cracked lid or fading label. Preventive routines save both product and peace of mind. If a chemical smells off or shows signs of caking, it’s time for safe disposal—not creative thinking about how to salvage a compromised batch.

Spills and accidents happen. Spill kits, absorbent pads, and clear disposal protocols provide a fallback when things slip through the cracks. Laboratories that think about worst-case scenarios in advance create safer environments. Most of the worst laboratory mishaps I’ve seen could have been avoided with a bit more planning and a quicker response.

Long-term safety depends on a shared sense of responsibility. Proper storage, detailed recordkeeping, and strong communication between team members pay off. At the end of the day, even the most mundane steps—sealing a lid, signing a label—hold up the fragile trust that keeps lab work productive and safe.

In day-to-day analytical labs, quality standards keep people on their toes. Octane-1-sulfonic acid sodium salt is a perfect example. Nobody in chromatography wants trouble from impurities—they play havoc with baselines and obscure peaks. Lab catalogs, when you check, usually offer this material at a purity of 98% or higher. Reliable supply chains focus on purities at or above 99%. Anyone who uses lower grades is probably operating under tight budgets or working outside the pharmaceutical, food, or environmental analysis markets.

One reason people are so picky: impurities sometimes mimic target analytes. These hangers-on interact with sample components, trade places during separation, or even create ghost peaks. That’s led to most buyers requiring a certificate of analysis that spells out purity and highlights the sodium content. If someone skips this step, they’re gambling with their data quality. In my own experience, running HPLC for trace analyses, I've watched contamination from lower grade reagents blow out separation windows and force wasted runs. Nobody wants to pay for extra solvents, time, or rework.

For most scientific applications, you’ll find grades like “for HPLC,” “analytical reagent,” and “technical.” “For HPLC” stands out, pulled from lots that test out at 99% or higher, sometimes as high as 99.5%. These batches have tight specs for moisture and sulfate, essential for stubborn methods like ion-pair chromatography. Analytical grade stocks work for research, quality control, and calibration. Anything labeled “technical grade” may save some money, but the risk for trace contaminants—heavy metals, extra organics—usually isn’t worth it in regulated labs. Labs with strict compliance requirements would rarely touch “technical.”

Solid suppliers provide full documentation: SDS sheets, batch-to-batch purity statements, and even trace element profiles. My own habit, before those first injections, includes double-checking certificates, especially if the order is from a new source. In regulated industries, inspectors want proof that every critical reagent—especially ion-pairing agents—meets stated specs. Even outside regulation, nobody likes having to redo a full week of sample prep due to off-brand reagents.

Labs watching the budget sometimes get tempted by off-brand or technical grade stuff, especially as supply chain pressures mount. A smarter approach: keep a trusted supplier on record, batch-test new shipments, and consider splitting high-purity bottles for routine work where the stakes aren’t as high. Even those in academic settings, where budgets sometimes get thin, find ways to share bulk orders across departments for cost savings without risking data quality. Price matters, sure—but reliability, documented purity, and proven results almost always save more hassle in the end.

If someone asks what to seek in octane-1-sulfonic acid sodium salt, the answer stays steady: look for high purity, well-documented lots, and stick to grades designed for your work. The safest road in analytical chemistry runs through reputable suppliers and traceable documentation, not just attractive price tags.

| Names | |

| Preferred IUPAC name | sodium 1-octanesulfonate |

| Other names |

1-Octanesulfonic acid sodium salt N-Octanesulfonic acid sodium salt Sodium octane-1-sulfonate Sodium n-octanesulfonate |

| Pronunciation | /ɒkˈteɪn wʌn sʌlˈfɒnɪk ˈæsɪd ˈsoʊdiəm sɔlt/ |

| Identifiers | |

| CAS Number | 5324-84-5 |

| Beilstein Reference | 1913705 |

| ChEBI | CHEBI:63689 |

| ChEMBL | CHEMBL3330600 |

| ChemSpider | 10234 |

| DrugBank | DB03766 |

| ECHA InfoCard | 100.007.423 |

| EC Number | 241-118-4 |

| Gmelin Reference | 92048 |

| KEGG | C01797 |

| MeSH | D015547 |

| PubChem CID | 8664 |

| RTECS number | RG0750000 |

| UNII | 8U5Z5QGZ0E |

| UN number | UN2581 |

| CompTox Dashboard (EPA) | DTXSID5020401 |

| Properties | |

| Chemical formula | C8H17NaO3S |

| Molar mass | 292.37 g/mol |

| Appearance | White to off-white powder |

| Odor | Odorless |

| Density | 1.44 g/cm3 |

| Solubility in water | soluble |

| log P | -3.2 |

| Acidity (pKa) | -2.8 |

| Basicity (pKb) | 12.2 |

| Magnetic susceptibility (χ) | -52.0e-6 cm³/mol |

| Refractive index (nD) | 1.438 |

| Viscosity | Viscosity: 50 cP (20°C) |

| Dipole moment | 3.1515 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 386.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1617.2 kJ/mol |

| Pharmacology | |

| ATC code | A16AX11 |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: "P264, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-0-1 |

| Lethal dose or concentration | LD₅₀ (oral, rat): > 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 2000 mg/kg |

| NIOSH | GV5950000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Octane-1-Sulfonic Acid Sodium Salt: Not established |

| REL (Recommended) | Not established. |

| Related compounds | |

| Related compounds |

Methanesulfonic acid Ethanesulfonic acid Propanesulfonic acid Butanesulfonic acid Hexanesulfonic acid sodium salt Nonane-1-sulfonic acid sodium salt Decane-1-sulfonic acid sodium salt |