Long before anyone used guanidine phosphate in industrial processes, early chemists wrestled with basic research in organic synthesis. Their curiosity, mixed with grit, led to compounds no one had dared to create. Guanidine, first derived in the 19th century from the oxidation of guanine, found a marriage partner in phosphoric acid to give us guanidine phosphate. After the mid-20th century, as synthetic fertilizer science moved past ammonia-based solutions, researchers noticed guanidine’s strong alkalinity and capacity to form stable phosphates. Chinese chemical industries picked up the thread faster than Western producers, and by the 1980s, guanidine phosphate began to pop up in fire retardants, agrichemicals, and even certain resins. Modern labs take these discoveries for granted, but it took generations of slow, stubborn progress—reinforced by cold data—to put this salt to work.

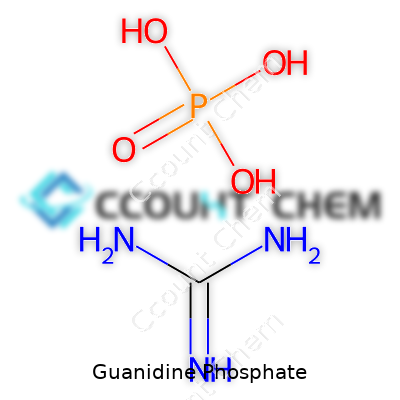

Guanidine phosphate comes as a white, crystalline powder with a distinct, slightly musty odor. It's used widely in flame retardant formulations, textile auxiliaries, and other specialty chemicals. Its chemical structure couples guanidine’s basicity with the mineral backbone of phosphate, creating a stable salt that seems unassuming but packs a punch in terms of reactivity. Industries use it not for glamour, but because it performs where performance matters—think commercial foam, fiber treatments, and hardening resins. In laboratories, researchers see it as a versatile intermediate, especially thanks to its convenient solubility in water and resistance to hydrolysis at ordinary temperatures.

This salt has a molecular formula of CH6N3O4P and a molar mass of about 141.1 g/mol. Under standard lab conditions, it remains stable, resisting decomposition unless heated beyond 260°C. Guanidine phosphate’s solubility in water sits around 22 grams per 100 milliliters at room temperature, giving it practical edge in many synthetic and application processes. It carries a slightly alkaline pH in solution, thanks to the basic guanidine cation. It doesn’t burn; instead, it supports flame retardancy by disrupting radical chain reactions in cellulose and plastic combustion. In handling it, I always pay attention to the faint ammonia-like aroma—the whiff tells me the stuff is fresh.

Industrial buyers look for a minimum guanidine phosphate purity of 98%. Any less and batch consistency drops, leading downstream applications to miss critical safety certifications. Bulk shipments arrive in polypropylene-lined sacks, usually 25 or 50 kilograms, clearly marked with hazard labels per GHS and local regulations. Key specs on the label include lot number, country of origin, storage recommendations, and a breakdown of typical cation and anion impurities. On a detailed data sheet, suppliers mention water content, assay methods based on titrimetric or spectrophotometric techniques, and heavy metal thresholds—lead, cadmium, and arsenic stay below a few parts per million.

Manufacturers make guanidine phosphate by reacting dicyandiamide with orthophosphoric acid. The exothermic reaction takes place in aqueous media, often under reflux, sometimes with a catalyst to accelerate conversion rates. After a few hours at mild temperatures, solid guanidine phosphate crystallizes out upon cooling. Workers filter, wash with chilled distilled water, and then dry the product in tray ovens or fluidized beds to drive off remaining moisture. This method keeps by-products at bay, especially cyanamide residues that can contaminate cruder batches. I’ve seen operations in person where safety hinges on strict temperature and pH monitoring; uncontrolled spikes can yield noxious fumes or even runaway reactions.

Guanidine phosphate’s chemistry comes from the nucleophilicity of the guanidine group and the stability of the phosphate anion. Reacting it with strong mineral acids, like hydrochloric or sulfuric, gives corresponding guanidine salts with new properties—for instance, guanidine hydrochloride is a classic protein denaturant. With formaldehyde or aldehydes, it helps produce resins and polymers with built-in flame retardancy. In the presence of non-oxidizing bases, the compound stays stable, but with strong oxidizers, it can break down, sometimes violently. Some chemists explore its use in slow-release fertilizers, exploiting its phosphate content, although uptake by plants doesn’t always match that of other phosphate sources.

Other than guanidine phosphate, suppliers call this salt phosphoric acid guanidine salt, guanidinium dihydrogen phosphate, or simply GDP. On both Chinese and Western markets, names can jumble, with some European safety sheets tagging it as guanidinium hydrogen phosphate. Each label traces back to the same backbone—what matters are the technical specs behind the name. In my own experience, avoiding confusion means double-checking the CAS number: 5423-22-3.

Handling guanidine phosphate takes foresight. Dust triggers mild respiratory irritation, while eye contact causes painful stinging. Manufacturers now use enclosed loading systems and NIOSH-approved masks during large transfers. Any spillage gets swept up, never blown away; inhaling fine powder isn’t worth the risk. Emergency instructions focus on rinsing skin with copious water and watching for delayed symptoms, since irritation can develop over a few hours. In storage, low humidity and temperatures under 40°C are essential to avoid caking or chemical degradation. Guidelines from organizations like OSHA and ECHA encourage frequent review of workplace hygiene, and call for periodic air quality monitoring.

Industries tap guanidine phosphate in places where passive fire protection could save lives: foam furniture, railway seating, construction panels, and non-woven fabrics. That’s just the beginning. Agroscience firms test it as an ingredient in slow-release fertilizers or animal feed additives, banking on its phosphorus and nitrogen punch for rising global crop needs. Electronics designers sometimes coat circuit insulation with phosphate-based retardants to meet flammability standards. Academic labs run it as a starting material for novel heterocyclic pharmaceuticals or materials chemistry. Hardly a pleasant classroom experiment, but the results support further research into green retardant chemistry.

Modern research in guanidine phosphate pivots on two focal points: environmental impact and functional efficiency. Chemists work to graft this salt onto biopolymers or blend it into eco-friendly resins. These tests aim to cut halogenated retardants, which release toxic dioxins during combustion, out of consumer goods altogether. Peer-reviewed data confirms guanidine phosphate enhances char formation and reduces smoke generation in model systems, translating to less toxic gas exposure for building occupants. Researchers from China, Germany, and the US run patent races to devise new applications, especially as recycling mandates tighten. In my own lab experience, blending guanidine phosphate in new materials—whether cellulose acetate fibers or polyurethanes—demands real patience. Every tweak to concentration or process parameters shifts performance significantly, but breakthroughs promise safer, more sustainable products.

Extensive rat and rabbit tests show guanidine phosphate has low acute toxicity by oral or dermal routes, with LD50 values above 2,000 mg/kg. Chronic exposure can impact renal and hepatic function, mostly due to long-term accumulations of phosphate. Most human risk comes through handling dust or accidental spillage, not ingestion. Some studies flag potential for algal bloom stimulation if wastewater effluent carries phosphate residues into natural waterways. Regulatory bodies like ECHA and US EPA keep monitoring for more data, as the full lifecycle assessment of guanidine-based retardants still holds unanswered questions. Real-world monitoring, as in recent Chinese flame-retardant factories, helps keep exposure below occupational limits set at about 1 mg/m³.

Interest in guanidine phosphate looks set to climb. Global demand for greener fire retardants and phosphorus recycling solutions keeps the compound in focus. Researchers continue to pursue safer, more durable resin composites, biodegradable agrochemical carriers, and advanced water treatment solutions all based around this backbone. Recycling plants and industrial labs in China, Europe, and the US push for closed-loop routes to cut waste and lower phosphorus loss. New regulations phasing out halogen-based retardants only add to the appeal. That said, as public scrutiny of chemical additives grows, producers will need to keep their processes transparent, invest more in toxicological data, and stay ready to pivot as regulatory winds shift. For everyday chemists and engineers, guanidine phosphate stands less as a miracle solution and more as a dependable player in the long project of safer, cleaner industry.

You don’t stumble upon guanidine phosphate in a household pantry. This chemical compound pops up in places you might not expect—fire safety, agriculture, and the cornerstones of industry. Some of us working in science and safety spend plenty of time thinking about what helps keep buildings standing, crops growing, and factories humming along. Guanidine phosphate plays a bigger role than most realize.

Guanidine phosphate brings something important to fire suppression and prevention strategies. In city office spaces lined with panels, in schools bustling with activity, there’s a quiet demand for materials that make it much less likely something will catch fire from a stray spark. This compound helps create fire-retardant panels, paints, and textiles. Working in school safety, I’ve seen the layers of protection that keep children safer and reduce insurance costs over years. After all, a building built with fire-retardant insulation or treated fabric gives occupants a better chance to respond in an emergency.

It’s not just about the initial installation—fire-resistant products reduce a building’s flammability longer than basic untreated materials. That kind of reliability matters when people’s lives depend on having a few extra minutes during a crisis.

Farmers in many countries use fertilizers infused with guanidine phosphate. There’s a direct benefit to the ground and crops: this compound provides nitrogen and phosphorus. Plants love both. Healthy yields result from soil stocked with nutrients, and these two elements are consistently among the most limiting on the world’s agricultural soils.

Growing up in a rural community, I saw firsthand how proper fertilization could boost family income and even affect what items showed up on the dinner table at home. Scientists point out that using guanidine phosphate can help with crop vigor and output, supporting farmers striving to produce more food with fewer resources. It’s not only about feeding more mouths—it’s about doing so with fewer negative effects on the land, if applied responsibly.

Industrial water treatment systems sometimes turn to guanidine phosphate as an additive. It helps keep machines running efficiently by controlling scale buildup. Factories and power plants benefit when their equipment runs smoother and lasts longer. Less clogging means fewer breakdowns and lower costs.

This detail often gets lost in daily operations, but those who’ve handled maintenance know how one chemical can save hours of labor and lots of replacement parts.

No chemical comes without questions about health and waste. Workers and environmental advocates regularly call for safe handling, storage, and disposal. Guanidine phosphate isn’t exempt from those concerns. Proper training in the workplace, clear labeling, and adherence to safety protocols matter here, too. Countries vary in their regulations. I’ve seen both good and bad examples depending on local laws and company habits.

We could support better communication between industries, scientists, and regulators to foster responsible use. That responsiveness keeps things safer for people living near factories, growing food, or sending their kids off to school.

Guanidine phosphate brings together fire safety, food security, and industrial performance. Whether you’re walking past fire-retardant panels in a hospital, eating bread made with wheat from a well-fertilized field, or working in a factory, chances are you’ve benefited from this compound without noticing. Paying attention to how and why it’s used can help make communities safer, more productive, and more resilient.

Guanidine phosphate shows up in different sectors, from fire protection products to specialty chemicals. At first glance, it looks just like another white powder. But bringing it into a workspace comes with more questions than just “what is it used for?” People ask about safety, health, long-term risks, and the right way to get it from bag to process line. These aren’t just technical questions. They're the kind workers and safety officers grapple with every day, especially those who have spent years among bags and barrels of fertilizers, metalwork chemicals, and additives.

Handling guanidine phosphate means thinking through the basics: Is this stuff toxic? What happens if it gets on your skin? The data points toward irritation on the skin and in the respiratory tract, although you probably won’t wind up with anything catastrophic if some lands on your hand and you wash it quickly. The bigger risk lies with dust clouds—breathing in any fine powder isn’t good for your lungs, and guanidine phosphate is no exception. Reading through the safety data sheets, you pick up a clear message: don’t eat it, don’t breathe it in, and don’t rub your eyes after touching it.

Over the years, certain habits stick. Gloves never sit forgotten in a drawer. A simple dust mask and goggles turn up on every workstation where powders get mixed or transferred. There’s a reason for this: even if incidents top out at minor sneezing or itchy skin, long-term carelessness has a way of turning small exposures into bigger problems. Fellow workers in fire retardant factories tell stories about one guy who never wore his gloves, and wound up with cracked, irritated hands every spring.

Employers play a big role. Having spent over a decade in facilities that deal with hazardous powders, I can say: real training, not just check-the-box videos, makes a difference. Workers pay attention when they see their supervisor toss out a set of dusty gloves and grab a fresh pair. Air quality monitoring, spill cleanup kits, and posted instructions help too, but what matters more is the tone set from the top.

There aren’t many chemicals that turn deadly from casual contact, but ignoring the cumulative effects of constant skin or eye exposure crosses a line. Guanidine phosphate doesn’t build up overnight. If you take steps to prevent breathing or touching it, odds stay on your side. I’ve watched a colleague go from skeptical to careful after a few lessons about skin irritation, especially after forgetting to wash hands before lunch.

Clear labeling helps avoid mishaps. Workers should see big, readable warnings, not faded symbols. I’ve noticed more facilities moving to pre-weighed packets, which cuts down on open-air transfer and dust. Regular personal monitoring, like checking skin and air quality, creates an environment where people look out for each other.

Guanidine phosphate does its job well in commercial settings when treated with respect. It isn’t a ticking time bomb, but it’s no kitchen flour either. In practice, safe handling means more than a checklist—it's about building a culture where everyone pays attention, takes precautions, and supports one another day after day.

Guanidine phosphate stands out in the world of chemical compounds. Its formula, CH₆N₃O₄P, gives a clear snapshot of its makeup. In practical terms, each molecule brings together one part guanidine and one part phosphoric acid. The result—a white crystalline solid—tends to show up in fertilizer labs, industrial cleaners, and sometimes in fire retardant research.

The reason this compound matters so much boils down to its power as a nitrogen and phosphorus provider. Crops often crave these nutrients. By delivering both, guanidine phosphate plays a quiet role in sustainable agriculture. During my time working with sustainable farming initiatives, I ran across plenty of fields where traditional fertilizers fell short. Fields using alternatives like guanidine phosphate often bounced back faster after heavy rainfall or stress.

Not everyone has a background in chemistry, so the real-world implications help tell the story. When you see plants growing faster and producing healthier yields, there’s more food on the table for families. For anyone running a farm, seeing results like this makes a chemical structure like CH₆N₃O₄P feel personal.

Like any synthetic compound, guanidine phosphate calls for respect on the shop floor. During my early years mixing and measuring powders, I learned to make safety part of the routine. This compound, while not as tricky as some toxic chemicals, still irritates the eyes and skin if handled carelessly. Wearing gloves, keeping the space well-ventilated, and reading up on the latest workplace safety sheets saved me a few headaches—literally.

In schools and small-scale research labs, there’s sometimes a rush to test out new chemical blends. Without proper storage or labeling, even something stable like guanidine phosphate can cause problems. Clear communication and reliable protocols make a big difference here.

Adding new substances into an ecosystem always brings risks. Phosphorus runoff, even from helpful compounds, can lead to algae blooms in nearby lakes. That’s one detail farmers in my region never miss—we all remember the year the creek turned green. Using precision agriculture tools, it’s possible to apply only what’s needed, right where it matters. This reduces waste, saves on costs, and keeps nutrients out of the water.

I’ve seen co-ops invest in better soil testing and tracking, which helps dial in fertilizer use. It may not solve every problem overnight, but less chemical overuse makes for cleaner water and healthier communities.

Research never stops. Scientists look for safer, more efficient ways to harness compounds like guanidine phosphate. From tweaking its formula for better plant uptake to developing slow-release versions, new ideas keep moving forward. Responsible use depends on learning, patience, and respect for both the chemistry and the landscape it touches.

From my days as a student to years in the field, I’ve seen that knowing what’s in a fertilizer—a clear formula like CH₆N₃O₄P—means more than memorizing numbers. It becomes part of a bigger picture, where science and food security walk hand in hand.

Guanidine phosphate doesn’t show up in most people’s garages or kitchens, but behind many science lab doors and factory gates, it’s a name that rings a bell. This chemical steps into roles where fire resistance and fertilization play a part. Just because you won’t bump into it at the grocery store doesn’t mean it comes free of risk. I remember visiting a warehouse in my early days of reporting and spotting sacks labeled with warning signs—half the trouble comes not from misuse but from careless storage. Fires, chemical burns, and ruined batches—one mistake at this level can go from headache to headlines.

Moisture turns guanidine phosphate into a problem real quick. It draws in water from the air and clumps together, so open bags or cracked containers set the stage for breakdown or accidental reactions. Chemistry textbooks often skip the day-to-day, but in real workspaces, a leaky roof or broken window means a ruined chemical. I’ve seen bags stuck to cement floors and staff blaming poor cleanliness, but the villain was always moisture. Securing containers against dampness, keeping the storage room dry, and checking seals—basic steps that save expensive replacements and protect people.

This chemical works best alone. Throwing it in with acids, chlorates, or oxidizing agents risks more than a few ruined test results. I once watched a careless worker move incompatible chemicals into the same area—luck turned what could have been a chemical nightmare into only a stern safety lecture. Fact: mixing the wrong substances can cause chemical fires or toxic gases. It’s not just about reading the label, but about coming back day after day to make sure nothing’s shifted or gone astray. Storing guanidine phosphate with a clear space around it, away from food, feed, acids, and oxidizers, keeps everyone safer.

I learned quickly that unlabeled bags and reused containers create chaos. Losing track of what’s inside invites mistakes—mix-ups, double dosing, or worse. Sturdy, clearly marked containers are a must. Training matters, too. Every person with access should know what they're handling and why improper storage leads to big problems. In workplaces I’ve interviewed, the places without strong labeling and training always seemed to struggle more with safety mishaps.

Plastic drums, sealed metal bins, or heavy-duty bags: what matters is spill resistance and a strong lid. You want something that won’t crack under a little pressure or leak out onto floors. High temperatures break down chemicals faster, so shaded areas or cool rooms give extra peace of mind. Chemical supply houses spend real money on climate controls for good reason. The cost of a ruined shipment or a bad spill always exceeds what it takes to set up sturdy shelving and ventilation.

No matter how neat the shelves look, an accident happens sooner or later. Quick cleanup and proper disposal set apart safe sites from hazardous ones. Clearly posted spill procedures, absorbents nearby, and a plan for chemical waste keep small problems from growing. I’ve seen emergencies handled in minutes because the right gear and a practiced team were ready for surprises.

Good habits matter more than any one rule. Audits keep careless stacking or lax labeling from going unnoticed. Investing in training and clear protocols protects investments and, more importantly, lives. Storage might look boring from the outside, but in any operation handling guanidine phosphate, it’s the backbone of safe, smart work.

Guanidine phosphate stands out in fire protection work. For folks maintaining buildings, running an industrial facility, or even managing a forest preserve, fire hazards mean constant concern. Coating materials with guanidine phosphate can help lower the risk of catching flame. The compound reacts with combustion products, stopping fires before they become disasters. Old textile factories, family-run paper mills, and new construction sites put fire safety at the top of the checklist, and this is where guanidine phosphate shines. Beyond just making things less flammable, it gives people extra time to respond, which saves lives and property.

Farmers and gardeners need fertilizers that keep soil healthy, crops strong, and harvests reliable. Guanidine phosphate provides a steady stream of nitrogen and phosphorus, two elements every plant loves. Some crops tend to exhaust the earth after only a few growing cycles, so a smart fertilizer replenishes the ground without side effects like groundwater pollution. Guanidine phosphate does its job by feeding plant roots just enough, boosting photosynthesis and making the next basket of tomatoes look better than last year’s. In places where unpredictable weather hurts fields year after year, farmers look for reliable ways to secure their livelihoods, and this fertilizer often is part of their answer.

Many companies making plastics, resins, and cleaner solutions choose guanidine phosphate for stability and predictability. Plastics manufacturers trust it to prevent their products from burning too easily. Glue and resin makers blend it into their mixes so their adhesives don’t become fire hazards. If you’ve ever worked near industrial paints or coatings, you may have noticed safety sheets listing guanidine phosphate as a flame retardant. The chemical environment inside a factory or a lab can be tricky, with temperature shifts and unpredictable reactions, but guanidine phosphate holds up in tough conditions.

Water treatment plants face tough regulations about what goes back into rivers, especially in cities with growing populations. Guanidine phosphate can neutralize certain metal ions that sneak into water from factories or run-off. It binds with pollutants, helping filtration systems remove them before water flows to tap or river. This lets cities and industries take responsibility for clean water, cutting back the chance of heavy metals making their way into the food chain.

Chemicals like guanidine phosphate don’t get much attention, unless something goes wrong. But for people on safety teams, researchers in basic science, or anyone who manages risk at work, its presence often spells the difference between “safe” and “sorry.” The importance of good manufacturing practice stands out here. Companies need to keep workers trained and informed, and storage must prevent leaks or contamination. Factories with proper labeling and ventilation take big steps towards keeping chemical use transparent and safe.

As new uses for guanidine phosphate emerge, clear labeling and continued research matter most. I’ve seen confusion about handling and disposal protocols cost time, money, and sometimes lead to dangerous accidents. Public education programs and straightforward regulations encourage careful use, especially in shared spaces where many hands take part. People working with these chemicals every day benefit from accessible training. Policy drives safe application, but it’s people who carry out each step—carrying lessons from past oversights into safer practices for the future.

| Names | |

| Preferred IUPAC name | phosphonoiminourea |

| Other names |

Phosphoric acid guanidinium salt Guanidinium phosphate Guanidine monophosphate Guanidinium dihydrogen phosphate |

| Pronunciation | /ɡwəˈnɪdiːn ˈfɒs.feɪt/ |

| Identifiers | |

| CAS Number | 13547-16-7 |

| Beilstein Reference | 4272544 |

| ChEBI | CHEBI:32517 |

| ChEMBL | CHEMBL2106242 |

| ChemSpider | 15142075 |

| DrugBank | DB11494 |

| ECHA InfoCard | 100.031.926 |

| EC Number | 214-171-6 |

| Gmelin Reference | 62667 |

| KEGG | C01881 |

| MeSH | D006154 |

| PubChem CID | 8666 |

| RTECS number | MF4300000 |

| UNII | 5G79WB3Q8E |

| UN number | UN1479 |

| CompTox Dashboard (EPA) | DTXSID3023570 |

| Properties | |

| Chemical formula | CH₆N₃O₄P |

| Molar mass | 179.09 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.452 g/cm³ |

| Solubility in water | Soluble |

| log P | -4.24 |

| Vapor pressure | Negligible |

| Acidity (pKa) | pKa = 13.6 |

| Basicity (pKb) | 11.5 |

| Magnetic susceptibility (χ) | Diamagnetic |

| Refractive index (nD) | 1.434 |

| Viscosity | 2.32 mPa·s (at 20 °C) |

| Dipole moment | 2.57 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 151 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1716 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1866 kJ/mol |

| Pharmacology | |

| ATC code | M05BA04 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes serious eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS06,GHS08 |

| Signal word | Danger |

| Hazard statements | H302, H315, H319 |

| Precautionary statements | P264, P280, P301+P312, P305+P351+P338, P330, P337+P313 |

| NFPA 704 (fire diamond) | 1-0-0 |

| Autoignition temperature | 400°C |

| Lethal dose or concentration | LD50 oral rat 4090 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 3500 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Guanidine Phosphate: not established |

| REL (Recommended) | 100 mg/m3 |

| Related compounds | |

| Related compounds |

Guanidine Phosphoric acid Creatine phosphate Amidinophosphate Guanidinium chloride |