Chemists first explored ethanesulfonic acid ethyl ester in the raw days of industrial chemical discovery, as the refining of sulfonic acid derivatives ramped up during the mid-20th century. In those labs, researchers pressed for alternatives to more volatile or less reactive compounds for both synthetic and specialty purposes. Over time, this simple molecule—often called ethyl ethanesulfonate—gained a place in research circles due to its useful sulfonate group combined with a manageable ethyl backbone. Early patents from the 1940s and 50s started outlining alkylation methods using it. By the 1970s, commercial producers added it to catalogs for labs chasing organosulfur chemistry. Many early publications honed in on toxicological properties after mutagenicity concerns surfaced within the context of pharmaceutical impurity screening.

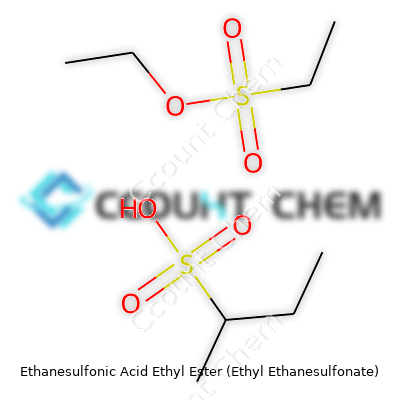

Ethanesulfonic acid ethyl ester goes by several aliases, including ethyl ethanesulfonate and ethylsulfonic acid ethyl ester. The compound provides both the reactivity expected from alkylating agents and a certain level of stability, striking a middle ground between aggressive modifiers like methylating agents and less reactive alternatives. For chemists, it opens doors to synthesizing sulfonic acid derivatives without excessive risk of overreaction or breakdown. Its structure—C2H5SO3C2H5—lends itself to manipulation in the lab while avoiding the unwelcome volatility of some simpler sulfur esters.

This ester appears as a clear liquid at room temperature, with a sharp odor reminiscent of strong acids mixed with light alcohols. Its boiling point ranges around 180–190°C, lowering the hurdles for distillation but still demanding respect through well-maintained fume hoods. It dissolves eagerly in polar organic solvents, but refuses to mix much with water, making it easier to isolate by extraction. With a density near 1.1 g/cm3, it doesn’t float or sink much relative to water when spills occur, so cleanup crews have to take care on both scores. On the reactivity front, the sulfonate group acts as a potent leaving group, making it a sought-after tool in organic substitutions. The molecule is stable under cool, dry storage, provided containers stay tightly sealed and far from open flames or strong bases.

Suppliers typically label containers with hazard warnings about toxicity, flammability, and potential environmental impact. Purity often exceeds 97%, with water and alcohols as noted trace contaminants. MSDS documentation highlights both inhalation and dermal risks, mandating sealed eyewear, chemical-resistant gloves, and laboratory coats at a minimum. Proper technical labeling also lays out storage guidelines: cool, dry, ventilated spaces removed from acids, strong bases, and oxidizers. Ethanesulfonic acid ethyl ester requires serialization and batch tracking on every drum, bottle, or vial, crucial for research transparency and recall purposes. Handling certifications sometimes pop up in procurement cycles to meet ISO and REACH scrutiny.

Chemists prepare ethanesulfonic acid ethyl ester through direct esterification of ethanesulfonic acid with ethanol, facilitated by concentrated acid catalysts such as sulfuric acid. The reaction runs under moderate heating and controlled reflux, with water generated as a byproduct. Quinones or resin beads may assist as scavengers to trap that water, driving the esterification to completion. Post-reaction work-up involves aqueous washes, drying over anhydrous salts, and distillation to purify the ester. Large-scale batches might rely on continuous flow reactors or microchannel setups to boost safety and throughput. Each batch gets tested by NMR, IR, and GC–MS to ensure absence of unreacted starting materials or hazardous impurities.

Ethanesulfonic acid ethyl ester shines as an alkylating agent, yielding ethyl-substituted products via nucleophilic substitution. It steps into organic syntheses of pharmaceuticals, specialty dyes, and surfactants, particularly in constructing sulfonated aryl or aliphatic cores. Under base-promoted conditions, it delivers its ethyl group to amines or thiols with high selectivity. Adding reducing agents to the mix reveals the ester’s potential for dealkylation and conversion back to ethanesulfonic acid, broadening its versatility. Electrochemical methods have also come into play for site-specific modifications, especially for labeling biomolecules in advanced research projects. Each pathway presents distinct byproducts and requires close attention to temperature and reaction time, but the general reliability of ethanesulfonic acid ethyl ester places it firmly on many synthetic chemists’ short lists.

On the market and in the literature, this ester turns up under names such as ethyl ethanesulfonate, ethylsulfonic acid ethyl ester, and sometimes just EES. The compound falls under registry numbers like CAS 4675-78-7 in chemical catalogues. Researchers often encounter legacy nomenclature in older journals or supplier documents—highlighting the importance of verifying product identity before introducing it into the lab. Cross-referencing supplier data with chemical abstract numbers and trade names avoids mishaps and ensures compliance, something regulatory bodies won’t overlook.

Labs working with ethanesulfonic acid ethyl ester adopt glove boxes, fume extraction, and chemical spill kits as baseline defensive tactics. Short-term exposure risks include irritation of skin, eyes, and respiratory tract; chronic exposure brings a darker cloud, given prior mutagenicity flags raised by toxicity studies. Regular air monitoring, emergency eyewash stations, and ready access to spill-neutralizing materials count as normal practice. Transportation pivots on secure packaging and tightly enforced labeling regulations. Disposal routes exclude drains, as local regulations classify the ester as hazardous waste headed for chemical incineration. Site supervisors often run drills with this compound as the scenario anchor, facing down the human and environmental risks through hands-on readiness.

Ethanesulfonic acid ethyl ester finds application mainly in organic syntheses where a reliable ethyl sulfonate group is needed. This includes small-molecule pharmaceuticals, intermediates for agrochemicals, and advanced material science efforts like sulfonated polymer electrolytes. Medicinal chemists use it to add ethyl groups to drug scaffolds and probe structure–activity relationships. In materials labs, the ester takes part in creating ion-exchange resins that end up in fuel cell membranes or industrial water treatment. Specialty dye makers exploit its strong leaving group, fine-tuning colorfastness and solubility for textile and ink products. Industrial-scale processes value its performance in building block formation, though concerns about safety, environmental fate, and regulatory scrutiny keep its broader adoption under regular review.

Most recent research around ethanesulfonic acid ethyl ester hones in on its use for chemical modification of bioactive molecules, including synthesis of antiviral and anticancer candidates. Analytical teams track and quantify residual ester as a potential genotoxic impurity in drug substances, leading to better purification and detection methods. In green chemistry circles, routes that generate less hazardous waste or recover starting materials get special attention, aligning with growing pressure to cut lab footprint. Collaborations between academic chemistry departments and industrial partners yield continuous flow and photochemical methods for cleaner syntheses. New analytical protocols developed for NMR and LC–MS speed up impurity profiling—essential, since regulatory agencies demand thorough risk assessments for compounds linked to mutagenicity.

Toxicologists remain wary of ethanesulfonic acid ethyl ester for a few sharp reasons. Animal studies from the late 20th century recorded bone marrow suppression and chromosomal mutations following exposure, and these findings pushed many pharma companies to develop more robust screening and containment protocols. Regulatory frameworks now treat it as a potential mutagen, tagging it for restricted handling and aggressive waste treatment across most jurisdictions. Modern labs use sensitive detection kits to catch even parts-per-billion traces in pharmaceutical products, often during the final release phase. Calls for more transparent, cross-border sharing of toxicological data have grown in both academic and industry circles, as the cost of oversight lapses hits public trust hard in the age of global drug manufacturing.

The track ahead for ethanesulfonic acid ethyl ester branches out. On one hand, demand for reliable alkylating agents isn’t slowing, given their crucial role in modern synthetic chemistry and advanced manufacturing. But the shadow of genotoxicity, coupled with tightening global chemical safety laws, pushes the chemical community to refine production, handling, and application strategies. Green chemistry holds out hope for designing safer analogs with similar reactivity but lighter health and environmental impact. Improvements in flow chemistry and in-line purification may keep this ester relevant longer, allowing chemists to use it in precise, contained formats. Research teams worldwide continue to publish on alternatives, exposure mitigation, and next-generation sulfonate chemistry, aiming to balance utility with responsibility. For now, ethanesulfonic acid ethyl ester stands as a symbol of both the promise and the pressure facing modern chemical innovation.

Ethanesulfonic acid ethyl ester, also known as ethyl ethanesulfonate, is something most folks outside of research labs haven’t heard of. I’ve spent my share of hours in chemical storerooms, and I can say its label stands out among routine solvents. Still, this compound carries weight in the chemistry world. It pops up on lab supply orders for good reason—most talks about it happen around shelves filled with experiment notes and safety goggles. Let’s pull back the curtain on the roles it plays and why discussions about its use deserve attention outside the walls of a lab.

Chemists rely on ethyl ethanesulfonate as more than just a tool. Its magic lies in how it acts as an alkylating agent, which means it helps attach ethyl groups to other molecules. In labs and in industry, this process allows researchers to build more complex molecules from simpler ones. I’ve seen it used while preparing analogs of existing pharmaceuticals in academic settings—sometimes, swapping a hydrogen atom for an ethyl group can totally change a compound's effectiveness or safety in the body. This sort of molecular tinkering speeds up the creation of potential new medicines, pigments, and crop protection chemicals.

Many researchers pick ethyl ethanesulfonate because the reaction happens cleanly and reliably under the right conditions. Speed matters in research; a straightforward reaction can open the door to running dozens of experiments in a day instead of a week. That kind of efficiency saves time and cuts costs, especially in the competitive world of drug discovery. Some classic textbooks, including March’s Advanced Organic Chemistry, list it among the stronger agents in this chemical family. It’s also found use in synthesizing certain dyes and plastics, which see daily use.

Ethyl ethanesulfonate isn’t just another bottle in a chemical cabinet, though. Tools powerful enough to change molecules often raise red flags when it comes to human and environmental health. Studies in toxicology have shown its potential to cause mutations in DNA—it’s flagged as a mutagen. I learned early in school that working with alkylating agents means double gloves, careful labeling, and strict training. Mutagenic chemicals are linked to risks like cancer, so labs institute protocols for storage, handling, and disposal. Fume hoods and proper ventilation keep air clean, while regulatory guidelines make sure this compound doesn’t end up in wastewater or landfill streams.

This is a good moment to talk about accountability for chemical use. Workers depend on clear labeling, up-to-date material safety data, and ongoing education. Many colleges and commercial labs run regular safety drills and audits. I believe keeping communities safe from unintended contamination calls for strong oversight by both government agencies and research institutions. Researchers are pushing for green chemistry alternatives—safer reagents that can do the job without long-term health worries. Sometimes switching up the method, even if it’s less convenient, cuts the risk to people and planet.

Interest in less hazardous alternatives is growing. Some research organizations have phased out risky alkylating agents when possible, turning instead to lower-toxicity chemicals or redesigned synthetic pathways. That push feels urgent as governments worldwide raise standards for occupational safety and environmental protection. Statistically, accidents involving mutagenic compounds have shaped stricter laboratory rules and more rigorous reporting.

Ethyl ethanesulfonate may never become a household name, but its impact runs deeper than many realize. By understanding the trade-offs, from time-saving chemistry to health and safety, industry and academia can make choices that respect both innovation and well-being. That’s a perspective as vital as any breakthrough compound.

Ethyl ethanesulfonate turns up in chemical synthesis and mutagenesis research for one main reason: it’s good at what it does, but it’s dangerous. Overlooking basic safety steps around this stuff comes down to gambling with personal health and the well-being of those nearby. Its reputation as a strong alkylating agent means it can mess with DNA, ruin clothes, irritate skin, and get into the air, so the focus stays on vigilance, not shortcuts.

Direct contact is where most issues start. Think eye protection, splash goggles, gloves made from nitrile or neoprene, and a lab coat that gets washed regularly and stored outside of living spaces. Even a brief splash leaves a mark. Plenty of us noticed headaches or painful rashes after a moment's lapse. Full-coverage footwear and working in a place with an eyewash station and emergency shower are worth the extra steps, because panic never helps after exposure.

Fumes from ethyl ethanesulfonate carry risk, both because of inhalation and their tendency to linger. Labs with functionally tested fume hoods or extraction fans can cut down sharply on airborne exposure. Without good ventilation, headaches, dizziness, or worse pop up even after short periods of use. Long-term health effects can show up months or years later, and there’s no turning the clock back.

Every container—no exceptions—should have a clear, durable label. No more guessing what’s inside. Storing ethyl ethanesulfonate with incompatible chemicals opens the door to fires or toxic mixing. Dry, cool, clearly separated storage saves property and lives far more reliably than DIY fixes or makeshift shelving. Never store it next to acids, strong bases, or oxidizers. A spill on the wrong shelf has started more than one fire over the years.

Spills happen, so having a plan written out with the right spill kit nearby is essential. Sweeping up dry powder, double-checking with test strips, and bagging contaminated rags or glassware keeps clean-up staff and coworkers safe. Wasting ethyl ethanesulfonate down the drain creates environmental and legal trouble. Hazardous waste pickup might sound inconvenient, but stories about contaminated water or surprise regulatory visits prove there’s no replacement for doing things by the book.

Nothing beats proper hands-on training, especially when someone new joins the team. Practicing with inert materials, spotting symptoms of exposure, and keeping records lets everyone know how chemicals move in and out of the workplace. Sometimes it feels like overkill, but in courtrooms or medical emergencies, clear records and well-trained staff have protected jobs and reputations more often than any amount of technical know-how.

Working with ethyl ethanesulfonate brings out the difference between checking a box and really paying attention. As the years go on, most seasoned chemists know coworkers who faced lasting damage skipping protection “just for a minute.” Modern safety data sheets, digital logs, and stronger workplace rules raise standards, but personal vigilance and accountability still build the biggest shield. Everyone, from new hires to senior scientists, owes it to each other to speak up if something looks or feels wrong.

Anyone who has worked in a lab knows the difference between textbook safety advice and the kind that grows out of real world experience. Ethyl Ethanesulfonate isn’t some backyard hobby material. This stuff packs a punch and respecting its properties isn’t about red tape—it’s about preventing real harm.

I remember the first time someone walked me through safety protocols for alkylating agents. There are a few compounds that turn a quiet storage room into a potential hazard zone, and Ethyl Ethanesulfonate lands squarely in that category. It’s volatile, it’s toxic, and it has the reputation to match. This chemical won’t wait for you to make mistakes, so small gaps in handling or storage turn into outsized problems.

No one wants to scramble after delivery. Plan storage before ordering. Look at the space itself first. If your chemical storage is in the corner beside the break area, move it. Only dedicated, well-ventilated rooms with exhaust hoods offer a fighting chance at reducing exposure. Traditional shelving doesn’t cut it for highly reactive chemicals—the container must sit on sturdy, chemical-resistant trays to catch leaks. Floors cleaned with water and soap won’t make up for sloppy containment.

Some folks leave solvents near a sunny window or under fluctuating temperatures. Ethyl Ethanesulfonate doesn’t forgive those choices. This compound stays stable between 2°C and 8°C, so a proper refrigerator, marked for chemicals only, solves most heat-related surprises. Never store this near strong bases, oxidizers, or acids. Once, a new hire stacked incompatible bottles on the same shelf and nearly created a recipe for disaster—the faint fumes caused enough worry to shut the lab down for deep cleaning. Separate spaces or different secondary containment works best.

It takes a single unlabeled bottle and a bit of carelessness to trigger panic. Stick clear, durable labels with the chemical name, hazard class, and the date of receipt. Use a printed format instead of handwriting—for quick identification if something goes wrong. Routinely check dates, cross-reference the inventory, and never get lazy with documentation. Substituting one bottle for another because “they look the same” isn’t just lazy, it’s dangerous.

Complacency grows over time. The first few times, you’ll grab your gloves and goggles, but distractions creep in. Handle Ethyl Ethanesulfonate inside a fume hood, with gloves and face protection. Just breathing the vapors or getting tiny drops on skin risks real damage. I’ve seen minor incidents where ignoring the safety glasses led to emergency eye wash runs. Don’t skip on protection, even for small transfer jobs.

Spill kits and first aid aren’t for show. You can’t predict every scenario, so at least guarantee quick access. Large absorptive pads, neutralizing agents, and emergency showers should all be within arm’s reach. If the site runs regular training drills, take them seriously. Living through one slow emergency response changes the way you think about “just in case” measures.

Sensible habits save more than lab audits—they prevent real harm. Inexperienced hands may cut corners, but chemicals like Ethyl Ethanesulfonate don’t give second chances.

Ethyl ethanesulfonate isn’t one of those names that pops up often in daily conversation, but it means business in chemistry circles. Its formula stands as C4H10O3S. This tells a story about what the molecule is made of, and a closer look uncovers a bit more detail about why it matters—not just in textbooks but also in everyday lab work and even in health discussions among scientists.

Take a glance at its formula and it starts to make sense: you get two carbon atoms from an ethyl group, two more from the ethanesulfonate part, then throw in ten hydrogens and round it out with three oxygens attached to a sulfur atom. Picture a chain with a sulfonate group (SO3)–that’s a sulfur double-bonded to two oxygens and single-bonded to another oxygen, giving a very reactive “tail.” Ethyl ethanesulfonate links this group to an ethyl side (–C2H5), which isn’t just decorative; it shapes how the molecule reacts with other substances. Chemists might draw it as CH3CH2OSO2CH2CH3—simple, but packed with reactivity.

Here’s the kicker: reactivity doesn’t always spell safety. Ethyl ethanesulfonate is an alkylating agent, meaning it can add its pieces onto other molecules, including DNA. This property made it a useful tool for mutagenesis studies where researchers wanted to introduce mutations and see what would happen. I remember learning about these experiments during college and thinking about the power and danger held within small bottles on the laboratory shelf.

The catch comes with its health risks. The same ability to change DNA that helps in research raises red flags for toxicity. Ethyl ethanesulfonate found its way into medical and chemical safety debates, and scientists now warn about its mutagenic effects. Proper handling, gloves on, fume hoods at full blast—those aren’t just rules but survival tactics.

No one likes to dodge hazards that sneak in under the radar. That’s why understanding the makeup and behavior of chemicals like ethyl ethanesulfonate matters. Labs, especially those in schools or with inexperienced staff, need clear training sessions outlining the risks. Safety Data Sheets offer templates for emergency responses and proper waste disposal. I’ve had coworkers rush through safety lessons and regret it later, so investment in training brings real returns in well-being. Regulators might require strict labeling and exposure limits, and these shouldn’t be ignored just because the chemical sounds obscure.

It’s tempting to cut corners in research or production, but personal stories from researchers who grew careless drive home the need for vigilance. Automation can cut down on direct human contact, reducing exposure. Wherever possible, swapping ethyl ethanesulfonate for less hazardous alternatives gives scientists and workers more peace of mind. Proper storage and disposal hold up as simple fixes that keep accidents off the record books. Sharing what goes wrong in one laboratory helps others avoid the same mistakes, fostering a safer culture for everyone handling reactive compounds.

Understanding how something like ethyl ethanesulfonate is put together and seeing the ripples that molecule sends out in work and health highlights why chemistry never sits idle in the lab. Staying informed and careful pays off, and science keeps moving because of it.

Ethyl ethanesulfonate isn’t just a mouthful to say. It packs a punch as a potent alkylating agent, a chemical class known for messing with DNA and often linked to mutagenic or carcinogenic effects. In my time writing about hazardous materials and responding to chemical incidents, I’ve seen how underestimating substances like this can land workers and first responders in real trouble. Even a small spill, if quickly shrugged off, can have lasting consequences.

Contact with this substance burns the skin and damages eyes. Inhalation irritates airway passages, leading to coughing, chest tightness, or a choking sensation. The real kicker comes from chronic exposure or substantial splashes—risk of cancer and long-term damage lingers. The International Agency for Research on Cancer lays out clear evidence about alkylating agents, leaving little doubt that even short exposure isn’t worth taking lightly. Nobody wants to end up with skin lesions or respiratory issues because of a moment’s carelessness.

Forget waiting for help unless it’s truly out of reach—the clock ticks fast with chemicals like this. I’ve learned in countless safety drills and workplace incidents that fast action counts more than fancy preparation.

Skin contact:Rip off contaminated clothing and get right into the shower, no hesitation. Wash every inch of skin that touched the stuff—don’t just dab at it. It stings like crazy, but soap and water break down traces fast so the chemical can’t dig in and do more damage. If the burn looks deep or the pain climbs, medical help is a must.

Eye exposure:Some folks freeze up here. Don’t. Get to an eyewash station and flush both eyes thoroughly, keeping them open for fifteen minutes. I once saw a worker skip this, thinking his eyes “felt fine.” He didn’t make the same mistake twice—one scare with chemical eye burns was enough. If vision blurs or won’t return to normal, the emergency room is the next stop.

Inhalation:The natural urge is to gasp or cough, but the priority is clean air. Leave the exposure area and breathe fresh air. I’ve treated folks who tried working it off indoors, and it just makes symptoms worse. Steady the breathing. Chest tightness or serious coughing means a doctor’s visit without delay.

Ingestion:This scenario doesn’t happen often, but if it does, don’t try vomiting it up. Drink water or milk to dilute the chemical, then seek professional medical care. Poison control centers will outline the steps, but don’t wait around hoping symptoms fade on their own.

Splash goggles, gloves, lab coats—these aren’t suggestions, they’re non-negotiables. Regular training helps drive the point home. It’s easy to get comfortable and cut corners, especially on busy days. I worked with a crew that treated every shift like a drill, making sure spill kits, rinsing stations, and emergency contacts were always a quick reach away. It set a standard for safety others came to respect. Air monitoring and local exhaust ventilation add another layer—simple controls reduce risk tenfold.

Every exposure to ethyl ethanesulfonate poses a real health threat. Training, good habits, protective gear, and quick thinking stand as the shield and first line against harm. Cutting corners, even for a minute, writes a ticket to the emergency room. That’s not a gamble worth taking in any field.

| Names | |

| Preferred IUPAC name | Ethyl ethanesulfonate |

| Other names |

EES Ethyl ethanesulphonate Ethylsulfonic acid ethyl ester Ethyl ethanesulfonate Ethylenesulfonic acid ethyl ester ES Sulfoethane ethyl ester |

| Pronunciation | /ˌɛθeɪn.sʌlˈfɒn.ɪk ˈæs.ɪd ˈiːθɪl ˈɛs.tər/ |

| Identifiers | |

| CAS Number | [126-62-9] |

| 3D model (JSmol) | `JSmol` 3D model string for **Ethanesulfonic Acid Ethyl Ester (Ethyl Ethanesulfonate)** is: ``` CCOS(=O)(=O)CC ``` This is the **SMILES** string which can be loaded into JSmol or other 3D molecule viewers. |

| Beilstein Reference | 1495050 |

| ChEBI | CHEBI:42580 |

| ChEMBL | CHEMBL155488 |

| ChemSpider | 18720 |

| DrugBank | DB08362 |

| ECHA InfoCard | 100.005.032 |

| EC Number | 211-849-4 |

| Gmelin Reference | 8597 |

| KEGG | C00989 |

| MeSH | D017181 |

| PubChem CID | 7571 |

| RTECS number | KG5775000 |

| UNII | 1L87BGA4SY |

| UN number | UN1609 |

| CompTox Dashboard (EPA) | DTXSID6022748 |

| Properties | |

| Chemical formula | C4H10O3S |

| Molar mass | 124.17 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.065 g/cm³ |

| Solubility in water | soluble |

| log P | -1.0 |

| Vapor pressure | 0.6 hPa (at 20 °C) |

| Acidity (pKa) | 1.53 |

| Magnetic susceptibility (χ) | -29.3×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.379 |

| Viscosity | 1.2 mPa·s (20 °C) |

| Dipole moment | 2.16 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 342.6 J/(mol·K) |

| Std enthalpy of formation (ΔfH⦵298) | -359.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1395 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V03AG05 |

| Hazards | |

| Main hazards | Toxic if swallowed, suspected of causing genetic defects, may cause cancer. |

| GHS labelling | GHS02, GHS06, GHS08 |

| Pictograms | GHS02,GHS06,GHS08 |

| Signal word | Danger |

| Hazard statements | H225, H301, H311, H331, H350 |

| Precautionary statements | P201, P202, P210, P264, P270, P273, P280, P301+P310, P303+P361+P353, P304+P340, P305+P351+P338, P308+P313, P311, P321, P330, P337+P313, P362+P364, P391, P405, P501 |

| NFPA 704 (fire diamond) | 1-2-0-Health:1-Flammability:2-Instability:0 |

| Flash point | 74 °C |

| Autoignition temperature | 350 °C |

| Lethal dose or concentration | LD50 oral rat 335 mg/kg |

| LD50 (median dose) | LD50 (median dose) for Ethanesulfonic Acid Ethyl Ester (Ethyl Ethanesulfonate): "185 mg/kg (oral, rat) |

| NIOSH | KK8225000 |

| PEL (Permissible) | 5 mg/m³ |

| REL (Recommended) | 0.5 mg/L |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Methanesulfonic acid ethyl ester Ethyl methanesulfonate Methanesulfonic acid methyl ester Ethanesulfonic acid methyl ester Ethyl sulfate Ethyl sulfonate |