Curiosity kicked off every breakthrough in chemistry. Ethanesulfonic acid, also known by its less tongue-twisting nickname ethanesulfonate, didn’t just show up out of nowhere. Decades ago, researchers pulling apart molecules in small university labs started to understand the strengths of smaller sulfonic acids. Bigger brothers like methanesulfonic acid earned early attention, but in time, the reliability and distinct reactivity of ethanesulfonic acid sparked more experiments. In the thick of the 20th century, researchers wanted strong acids that weren’t heavy polluters and had a knack for handling electronics and life sciences. Ethanesulfonic acid found its lane once instrument analysts and biochemists saw its clean, predictable action compared to older, messier choices.

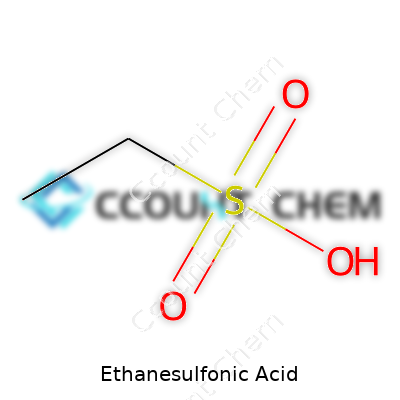

Ethanesulfonic acid proves useful because it’s straightforward. Chemists recognize its clear liquid or sometimes mildly yellow appearance, slightly spicy odor, and ability to jump into all kinds of reactions. In many research settings and chemical plants, this acid acts as a practical workhorse. While some acids melt glass and eat through cabinets, ethanesulfonic acid’s stability makes it friendlier to handle, without losing that valuable punch all strong acids carry. Its chemical formula, C2H6O3S, looks simple but turns up in all sorts of recipes, from new electrolyte mixes in batteries to more intricate roles in pharmaceuticals.

People sometimes think a strong acid always means danger or epic levels of corrosion, but ethanesulfonic acid challenges that lazy view. Its melting point hovers above room temperature, while its boiling point lands around 255–257 °C. When water mixes with it, it dissolves easily and doesn’t throw off unpredictable fumes. Its acidity ranks strong, sliding just below classic mineral acids like sulfuric, making it a go-to for reactions in water where precision counts. Stability matters for safety but also for getting consistent lab results, and ethanesulfonic acid’s reluctance to decompose in storage means fewer headaches for everyone’s inventory.

Nobody wants surprises in chemical supply chains. Reputable suppliers label ethanesulfonic acid with CAS number 594-45-6, flashing its identity for everyone from warehouse staff to quality controllers. Pure lots test over 99%—and trace elements like heavy metals face strict bans, especially for pharmaceutical or analytical-grade product. Clear hazard pictograms, handling cautions, and protective measures track with global standards. Transporters and companies stack certifications, like ISO and REACH, because that builds trust and avoids cross-border trouble. Every bottle or drum carries batch numbers, expiry dates, and production details. This isn’t bureaucracy—it’s how accidents, recalls, and costly downtime stay out of the news.

Manufacturers have landed on a few practical ways to create ethanesulfonic acid. The most common route starts with ethylene, turning it into ethane sulfonic acid through sulfonation using sulfur trioxide or oleum. Afterward, the crude mixture heads through labor-intensive purification. Chemists learned early on that poorly washed ethanesulfonic acid drags in dangerous impurities, so producers push water-washing, slow distillation, and even active carbon filtration to nail pharmaceutical and electronics specs. Small tweaks, like lower reaction temps or purer sulfur trioxide, can make bulk production safer and cheaper. Some innovators hunt for greener, less energy-hungry routes by using catalysts that work at lower heat or swappable, recyclable solvents.

Ethanesulfonic acid doesn’t sit in a corner, waiting for someone to sprinkle it on a reaction. It offers a steady, reliable base for building more advanced molecules. Chemists love its stubborn stability; it’s tough enough to survive gritty industrial synthesis and gentle enough to act as a non-volatile strong acid in sensitive settings. Transforming it into ethanesulfonate salts opens doors in pharmaceuticals, where salt forms can tweak how drugs behave in the body. It reacts smoothly with alcohols, amines, and even organometallic compounds, giving researchers tools for invention instead of endless troubleshooting. Those trailing hydrocarbon chains lend themselves to further modifications, leading to surfactants or specialty chemical additives.

Over time, confusing names get in the way of real work. This acid dodges that trap by carrying a short list: ethanesulfonic acid, ethylsulfonic acid, and sometimes the shorthand EtSO3H. In technical catalogs, pharma supply lists, and regulatory paperwork, “ethanesulfonic acid” holds the top spot. International brands and supply chains stick to these main names to cut down errors and streamline import/export reporting. Labs use abbreviations in research papers, but the CAS number always serves as the tiebreaker when disputes pop up over purity or hazards.

Dealing with ethanesulfonic acid takes respect and well-drilled habits. Even stable acids cause burns or big spills, and every chemist has horror stories about rushed handling. Chemical plants and research centers build layers of safety: goggles, acid-resistant gloves, lab coats, and the occasional full face shield for splashy jobs. Ventilation matters too—strong acids can fog up air in tight rooms, so fume hoods and exhaust fans are basic protocol. In storage, the acid never gets stacked near bases or oxidizers, and grounding rules block static sparks. Transporting large volumes requires tough containers, reliable seals, spill kits, and up-to-date hazard plans. Staff training focuses on what to do before accidents happen, not scrambling after. Everyone from janitors to senior chemists benefit when cleanup kits and well-marked eyewash stations sit right around the corner.

Most strong acids don’t cross from the lab bench to production lines with ease, but ethanesulfonic acid moves seamlessly into electronics, pharmaceuticals, batteries, and even specialty agriculture. In medicine, it helps create stable salt forms for injectable drugs, improving shelf life and absorption. Battery makers use ethanesulfonic acid as a dopant in electrolytes, carving out better charge cycles and longer stability in next-gen batteries like those built for electric vehicles. Water treatment plants respect its predictability—dosing strong acids without swinging pH levels wildly cuts down on environmental risk and maintenance. Some chemical manufacturers twist its chemistry to design niche surfactants with low toxicity, turning up in detergents that break down more easily after use. My time assisting in a startup lab taught me first-hand that a drop of ethanesulfonic acid goes a long way in optimizing synthesis without clogging up filters or melting equipment.

Research groups find ethanesulfonic acid a plain but powerful tool. Dozens of times, I watched students and postdocs lean on it for clean, repeatable results in catalysis, peptide synthesis, and even reactive ion etching. Drug makers hunt for acid forms that blend potency, low toxicity, and ease of purification; ethanesulfonic acid matches these needs more often than flashier contenders. In green chemistry labs, teams tinker with less harsh production techniques, pulling in biocatalysts and solvent-free methods. Some teams probe its use in emerging technologies like proton exchange membranes for hydrogen fuel cells, chasing after more efficient, durable materials. Every year, new patents pop up exploring blends, derivatives, and recycling methods, showing that even classics like ethanesulfonic acid still spark innovation.

Toxicology never fades into the background with strong acids. Early studies painted ethanesulfonic acid as less aggressive to organs than heavy hitters like hydrochloric, but contact burns and inhalation risks demand serious attention. Lab animal testing, supported by in vitro assessments, pointed out low acute systemic toxicity but flagged lingering effects from eye or skin contact. Repeated, low-level exposure shapes safe handling rules; agencies like the ECHA and US EPA update guidance as new data rolls in. Wastewater concerns push researchers to develop rapid neutralization methods so accidental spills don’t harm plant and animal life. Training and monitoring always figure into operational policies, because real-world slips—like unlabeled bottles or missing gloves—still pop up no matter how well posters warn about hazards.

Ethanesulfonic acid may never grab headlines, but its predictability and versatility secure its future in research and industry. Companies setting up green battery gigafactories see a future for sturdy, clean-dissolving acids that fit renewable energy benchmarks. Drug innovation around biologics and complex molecules leans on reliable acid partners for new formulations. I’ve watched university labs shift focus toward bio-based synthesis and smaller environmental footprints, betting ethanesulfonic acid can shape new, lower-waste manufacturing streams. Regulatory changes and tighter workplace standards drive up demand for acids with lower human and environmental impacts. If recent research holds, chemists will keep reimagining ethanesulfonic acid’s potential—pushing it well beyond old stereotypes of dangerous, one-trick reagents.

Ethanesulfonic acid often flies under the radar, even for some working in chemical industries. If you haven’t run across it in a lab or a pharmaceutical plant, it’s a name that sounds a bit intimidating. Still, this compound plays a bigger part in our world than many realize. Its clean, strong acid profile makes it valuable wherever precise chemical reactions matter.

Many modern drugs rely on effective salt forms to improve how the body can absorb and use them. Over the years, chemists have learned that using ethanesulfonic acid to form what’s called an “ethanesulfonate salt” brings real advantages. Take the epilepsy drug ethosuximide—the sodium ethanesulfonate form dissolves better than the basic compound, giving doctors more flexibility when dosing. It doesn’t just stop with one medicine; researchers often test this acid with new drug molecules to see if it improves a pill’s stability or makes it easier for the stomach to handle.

Despite most folks picturing beakers and colored liquids, a real laboratory often comes down to choosing the right building blocks for experiments. Ethanesulfonic acid works well as a strong acid and buffering agent in chemical analysis. For example, high-performance liquid chromatography (HPLC) relies on precise pH control to separate compounds that might otherwise clump together. Using this acid, scientists keep reactions right where they want them. In my own college years, swapping in ethanesulfonic acid made a night-and-day difference in some finicky protein separations—results got more predictable, less frustrating.

Beyond pharmaceuticals, chemists depend on this acid to alter raw materials in ways that open doors to new products. Ethanesulfonic acid acts as an intermediate for dyes, detergents, or even certain advanced plastics. In these roles, it can transfer its sulfonic group to another molecule, creating substances that handle surfactant duties (like helping oil and water mix) or boosting the strength of polymer chains.

Some new “green” detergent technologies, focused on reducing environmental impact, use by-products of ethanesulfonic acid chemistry. Companies prefer acids like this one because it dissolves easily in water and leaves behind fewer residues that harm aquatic life — an important move as stricter regulations come down the pipeline.

Not all strong acids can claim to be relatively safe to work with. Ethanesulfonic acid’s straightforward behavior and lower volatility keep it from being as risky as others, but direct skin contact can still burn, and inhaling the fumes isn’t smart. Keeping these risks in mind, industry standards push for good ventilation and proper gloves, much like they do with other strong chemicals. As stricter environmental and workplace guidelines take hold, labs and factories look for options that balance safety with sheer effectiveness—ethanesulfonic acid fits that bill in many scenarios.

Looking to the future, there’s room for more research. Alternative acids might emerge, but for now, this compound’s reliable properties help drive new developments in medicine, manufacturing, and scientific discovery. The work chemists do with ethanesulfonic acid often stays invisible to the public, but its impact stretches from pill bottles to cleaner streams.

Ethanesulfonic acid doesn’t draw crowds at science fairs, but in the lab, it’s a regular guest. Its chemical formula, C2H6O3S, might look like a random mashup of letters and numbers, but it reflects a structure that holds a lot of power in chemistry. You have two carbons, six hydrogens, three oxygens, and one sulfur coming together. For chemists, that combination is more than a trivia answer—it shapes how the compound behaves in living systems, pharmaceutical labs, and industrial setups.

It’s easy to glance over a chemical like ethanesulfonic acid and think it belongs tucked away in a dusty bottle. For those working with organic synthesis, the difference between C2H6SO3 and some other arrangement can break or make a project. I remember sitting in an undergraduate lab, running a basic buffer prep, and messing up the identity of my sulfonic acid additive. The wrong formula meant my buffer didn’t do its job. Sulfonic acids, including ethanesulfonic acid, often offer stability and strong acidity. They’re used to tweak reactions or influence the final product’s purity.

Pharmaceutical companies often turn to ethanesulfonic acid to form the magnesium salt of certain drugs. That salt can make all the difference for a formulation’s effectiveness. Beyond pharma, this acid pops up in catalysis and even in certain detergents. Scientists and safety officers need to recognize that the formula isn’t just symbolic—it tells them how to handle the compound and predicts how it’ll react under different conditions. For me, remembering the right number of oxygens and that sulfur atom serves as a quick red flag or green light when cross-referencing safety data sheets at work.

Mistaking the chemical identity leads to more than just a botched reaction. Safety risks climb, budgets take a hit, and in regulated industries, paperwork becomes a nightmare. The U.S. Environmental Protection Agency (EPA) and Food and Drug Administration (FDA) both require complete, accurate documentation down to the chemical level. A skipped check on the chemical formula opens the door for compliance issues and even legal trouble. I’ve sat through meetings where a mislabeled compound delayed a product launch by months. The team scrambled because someone copied the wrong formula from an outdated spreadsheet.

Getting formulas right goes beyond rote memorization. It’s about fostering a culture where people question odd-looking ingredients and double-check work. I always tell new interns: Don’t trust a label just because it’s printed clearly. Pull up the Material Safety Data Sheet (MSDS), look at the formula, match it against your protocol. Institutions can support this through regular training, quick-access safety databases, and encouraging team members to speak up if something seems off. In the real world, lab managers who audit documentation catch these errors long before they reach the supply chain.

Ethanesulfonic acid, with its explicit formula C2H6O3S, deserves more respect than a footnote in a catalog. Misidentification creates headaches from the benchtop to the board room. Precision in chemistry protects both the outcome of experiments and the people performing them. The extra minute spent double-checking a formula repays itself tenfold—whether you’re a student or a senior scientist. Staying sharp on basics like the chemical makeup of ethanesulfonic acid simply makes science safer and progress smoother.

Ethanesulfonic acid sounds technical, but it’s a chemical used for plenty of purposes, from making pharmaceuticals to helping with chemical syntheses in labs. Anyone working around chemicals earns a healthy respect for their properties, especially for strong acids, since accidents don’t give second chances. So, straight talk: Is ethanesulfonic acid hazardous? Is it corrosive? The short answer is yes to both, and most chemists know the risks from firsthand experience in the lab.

This acid packs a punch, similar to other sulfonic acids. Spilling it can cause burns. If it splashes in your eyes, you’re in for a world of trouble. The pain, redness, swelling—these are not rare stories, but regular reminders on every chemical safety poster. Getting it on your skin can lead to blistering and tissue damage. Inhalation can irritate the throat, nose, and even damage your lungs with higher exposure. Swallowing, even small amounts, demands medical attention.

I’ve seen firsthand what happens when careless hands ignore glove protocol. Ethanesulfonic acid eats away at flesh and can destroy clothing. Its strong acidity eats through metal and corrodes lab benches given enough contact. This is not mild vinegar or lemon juice: it’s in the league with sulfuric and hydrochloric acid. In my early days, a mentor showed a melted glove after a spill—lesson burned in just as vividly as on the glove itself.

Ignoring this acid’s risks courts disaster. Injuries aren’t rare in settings that handle strong acids. Data shows that acids cause most incidents in labs, with corrosion injuries among the most painful and hardest to treat. Many factories keep occupational exposure limits in mind, and for good reason. Safety protocols aren’t just legal red tape. They save sight, skin, and lives.

Improper disposal can contaminate water and kill aquatic life. Strong acids shift pH and create knock-on problems for both sewage systems and treatment facilities. The ecosystem can’t just bounce back when corrosive chemicals hit the water, and fish kills are silent but devastating proof.

Smart workers wear goggles, thick gloves, and long sleeves. It’s not paranoia; it’s basic wisdom in any environment with strong acids. It’s easy to forget how quickly an accident can happen. Clear labeling goes a long way. Anyone can make a mistake with an unlabeled bottle. Ventilation keeps dangerous vapors away from lungs. In the lab, a fume hood or good airflow becomes a second line of defense if something gets knocked over.

Spill kits need to stay within arm’s reach. Neutralizing agents such as sodium bicarbonate are a must. No one wants to scramble for supplies mid-crisis. Regular training makes a difference, not just yearly checklists but hands-on walkthroughs, so reactions turn into muscle memory under stress.

In manufacturing or larger sites, regular audits catch weak spots in storage, record keeping, or emergency procedures. Seamless communication between safety teams and operators helps spot hazards fast. The environmental side calls for robust containment, with bunds and lined storage keeping leaks from ever touching soil or water.

Working with ethanesulfonic acid requires respect, not fear. With decades of practice, I’ve seen sites where safety culture thrives, and workers feel empowered to call out hazards or stop a process if something feels off. That sort of environment takes work but pays off, both by avoiding pain and by keeping a workplace running smoothly. Staying sharp on solid protocols saves more injuries than luck or bravery ever could.

Dealing with strong acids always calls for care, but ethanesulfonic acid brings its own set of challenges. This isn’t just another bottle to set on a shelf. From colleges to industrial labs, anyone who has handled reagents like this knows accidents come from simple oversights—improper storage, poor labeling, rushed transfer. Acid doesn't care how experienced you are.

A few years back during a university project, I watched someone pick up the wrong container from a cluttered chemical shelf. The result was a small spill, a panic, and a lot of wasted time. That day, the impact of sloppy storage hit home. It only takes one mistake to risk skin, lungs, or even the lab itself.

To keep folks safe, storing ethanesulfonic acid means giving it space out of sunlight, away from heat, and locked up tight. Nobody working near acids wants to share storage with bases, solvents, or anything likely to catch fire. Mix-ups can create toxic fumes or even start fires. Good ventilation helps limit the risk of inhaling any fumes that might escape.

Labeling must be more than just a scratched marker. If a bottle looks identical to another, confusion grows. A label stating “ethanesulfonic acid,” clear hazard symbols, and a purchase or open date stops shortcuts in their tracks. Racking up compliance paperwork shouldn’t be the focus—good labeling keeps everyone on the same page and cuts confusion in a crisis.

Comfort isn’t a reason to skimp on gloves or splash goggles. Skin contact may burn, fumes can irritate your nose and throat, and nobody wants acid in their eyes. I once watched a colleague save a nasty situation by wearing thick nitrile gloves. Regular laboratory coats, splash face shields, and chemical-resistant aprons round out the basic gear list.

Transferring ethanesulfonic acid between containers feels safe with a fume hood and the right siphon or bottle-top dispenser. Tilting the jug and hoping for the best belongs in a chemistry blooper reel. Never use glass with cracks or containers from other chemicals—acids react, and surprise reactions don’t play favorites.

Regular reminders and easy-to-read Safety Data Sheets set a tone for good habits. Well-trained staff feel more comfortable stopping unsafe actions. Posting emergency shower and eyewash locations—visible and accessible—can spell the difference in exposure events. Keeping sodium bicarbonate or neutralizing agents in arm’s reach helps clean up spills before they spread.

Ethanesulfonic acid fits into many research and manufacturing workflows, but nobody likes dealing with the aftermath of a rush job. Engineers, researchers, and facility managers hold the key to safer labs: structured routines, solid checks, and making sure every person using the acid knows the risks before they open the lid. That’s what keeps the work afloat, and everyone healthy.

Ethanesulfonic acid might sound like another chemical buried in the back of the supply closet, but its impact reaches far into research and manufacturing routines. I remember working late in my old university lab, hunting for a buffer that would stay stable even when other common acids started losing their grip. That's where ethanesulfonic acid came in—throw it into a buffer system, and your results stay steady. This acid doesn’t play tricks with evaporation or temperature swings, which helps scientists keep their experiments consistent.

Ask any analytical chemist running high-performance liquid chromatography (HPLC) what makes a difference during a tough separation, and you’ll hear ethanesulfonic acid mentioned. It brings predictable ionic strength, supporting sharp peaks and reproducible retention times. Sulfonic acids, like this one, help control pH without clogging up the instrument lines or leaving behind sticky residues. A researcher chasing tiny impurities in pharmaceutical testing needs that kind of reliability. The FDA outlines strict protocols for drug quality, and the presence of this acid as a buffer in chromatography methods helps labs hit regulatory targets.

In drug formulation, chemists use ethanesulfonic acid to create ethanesulfonate salts, often called esilates. These salts can change a drug’s properties, helping it dissolve better or stay stable until it reaches the bloodstream. It’s not just about theory; real patients benefit from pills that dissolve as they should and release medicine at the right spot. I’ve seen how formulation tweaks enabled by simple acids can move a candidate drug from failed trial to effective treatment.

The industrial world sticks with things that work. Ethanesulfonic acid joins cleaning blends that cut through stubborn mineral deposits in pipes and equipment. In electronics, manufacturers use it as a catalyst during surface treatment processes. This acid can activate metals to better receive coatings, keeping device failures at bay. A factory dealing with scale in their heat exchangers or a semiconductor line improving adhesion owes a nod to what chemists have learned about this humble molecule.

Stronger acids bring risks, and ethanesulfonic acid has its share. Splashing it on skin hurts, and breathing in vapors makes for a bad day. Responsible teams train properly and keep bottles tightly capped, with backup ventilation in place. Companies can reduce hazards by using diluted forms or automating dispensing so fewer hands get exposed. Waste treatment should neutralize residues before discharge, following the EPA guidelines for sulfonate-containing wastes. In the world of lab and industrial safety, shortcuts only invite trouble.

Research teams keep pushing for greener alternatives, wondering if they can find acids with less environmental impact but the same chemical strength. So far, for certain pharmaceutical and lab jobs, few options measure up. The big goal remains—safe practices, smarter disposal, and respect for the chemistry that keeps experiments and products moving forward.

| Names | |

| Preferred IUPAC name | Ethanesulfonic acid |

| Other names |

Methanesulfonic acid MSA Mesylic acid |

| Pronunciation | /ɛˌθeɪn.sʌlˈfɒn.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 126-44-3 |

| 3D model (JSmol) | ``` Ethanesulfonic Acid | JSmol 3D Model String: CCS(=O)(=O)O ``` |

| Beilstein Reference | 1102947 |

| ChEBI | CHEBI:42748 |

| ChEMBL | CHEMBL1200213 |

| ChemSpider | 21105706 |

| DrugBank | DB03864 |

| ECHA InfoCard | 100.004.107 |

| EC Number | EC 200- eth64-2 |

| Gmelin Reference | 8226 |

| KEGG | C01838 |

| MeSH | D017348 |

| PubChem CID | 63968 |

| RTECS number | KS7175000 |

| UNII | 58A480786E |

| UN number | UN3265 |

| CompTox Dashboard (EPA) | Q4100925 |

| Properties | |

| Chemical formula | C2H6O3S |

| Molar mass | 110.17 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.201 g/mL at 25 °C |

| Solubility in water | very soluble |

| log P | -2.14 |

| Vapor pressure | 0.01 mmHg (20°C) |

| Acidity (pKa) | 1.85 |

| Basicity (pKb) | -10.7 |

| Magnetic susceptibility (χ) | -7.5×10^-6 |

| Refractive index (nD) | 1.390 |

| Viscosity | 2.1 mPa·s (25 °C) |

| Dipole moment | 3.18 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 181.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -748.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -964 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V03AB33 |

| Hazards | |

| Main hazards | Corrosive, causes severe skin burns and eye damage, harmful if swallowed or inhaled. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS05 |

| Signal word | Warning |

| Hazard statements | H302, H314 |

| Precautionary statements | P280, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 3-0-1 |

| Lethal dose or concentration | LD50 oral rat 649 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral Rat 1950 mg/kg |

| NIOSH | NA1999 |

| PEL (Permissible) | No PEL established |

| REL (Recommended) | Ambion, 20 mM |

| Related compounds | |

| Related compounds |

Methanesulfonic acid Propanesulfonic acid Benzenesulfonic acid Ethanesulfonate Sulfonic acid |