Back in the early days of heavy metal detoxification research, dimercapto compounds appeared as lifesavers in industrial and medical circles. Throughout the 20th century, scientists looked for reliable ways to pull mercury, lead, and arsenic out of living systems. Classic options had their shortcomings. Then dimercapto-1 propanesulfonic acid emerged, adding a sulfonic acid group, bringing better solubility in water and lower risk of side effects. Researchers tested different salt forms, finally landing on the sodium salt monohydrate for stability and handling. By the 1990s, its presence in laboratory and clinical settings grew as academics compared safety and effectiveness over traditional chelators. Now, the compound anchors itself within the history of chelation chemistry, holding a spot among scientists who chase better patient outcomes and safer chemical processes.

Dimercapto-1 propanesulfonic acid salt monohydrate often presents as a white to pale yellow solid, usually fine and free-flowing. It shows up in bottles stamped with hazard pictograms—those black exclamation marks or health hazard icons—but despite these warnings, the substance has become a staple in toxicology and environmental remediation labs. Its primary job revolves around binding harmful metals in biological and environmental samples. Out on the market, you find it with lot-specific certification sheets, confirming purity and critical trace impurity levels, addressing concerns from researchers who want trace consistency. Its form—hydrated salt—means fewer clumping issues and longer shelf life compared to anhydrous alternatives. Major distributors differentiate supply through lot certification and careful package labeling, which helps people trust what's inside each flask.

This compound dissolves quickly in water under gentle stirring. That solubility comes from the sulfonic acid group paired with the sodium salt. When you open the container, you might catch a faint odor reminiscent of sulfur, nothing overpowering, just a faint promise of its chemistry. Its molecular weight clocks in around 238 g/mol, rising slightly with the monohydrate form. The melting point doesn’t reveal much with common laboratory equipment because the monohydrate decomposes before reaching a true melt. Under normal storage, the compound keeps stable for years; moisture actually helps maintain its integrity. Anyone handling it without gloves will soon regret skin exposure, since sulfur groups latch trap metals and possibly irritate the skin. Bottles carry labels about minimizing air and light exposure—both can degrade the compound, especially if left uncapped near a window.

Most suppliers list around 98–99% purity for research-grade material, with sodium as the primary counterion. Labels feature the product name, CAS number (4076-02-2), the precise hydration state, and lot-specific values for chloride and trace metal contamination. Barcodes, hazard icons, and safety instructions appear next—sometimes overkill, though they've moved to QR-codes for retrieving up-to-date Safety Data Sheets (SDS). Regulatory guidelines fixate on transport and storage, since powders this reactive attract the wrong kind of attention if mishandled. Technical datasheets gather everything a lab auditor expects—shelf life, recommended storage below 25°C, and ventilated dry conditions. Chemists I’ve met rely on those printouts to tackle certification and procurement paperwork, sidestepping confusion from ambiguous supplier names.

This compound typically starts with the reaction of 1,3-propanesultone and a dithiol precursor, often under basic aqueous conditions. The process takes careful temperature control and clean-up afterward—for every chemist who skips the slow addition steps, yields drop, contamination rises, and the product ends up too impure for analytical work. Water content gets fine-tuned by drying under vacuum conditions, then introducing a calculated amount of water vapor to lock the monohydrate form. At industrial scale, crystallization from water or ethanol brings out that fine, white powder. People often fuss over batch consistency not because of the steps themselves, but how impurities from incomplete conversions stubbornly linger unless purification is spot-on. Years back, one batch I tested had residual precursor, which complicated everything downstream. Vigilance at each synthesis and drying point gives a much more reliable final product.

Chemists gravitate towards the dithiol group—the two sulfur atoms make this compound a prime candidate for chelating soft metal ions. In practice, the sodium salt binds lead, mercury, and cadmium, forming soluble complexes that are easier to separate or eliminate. You can oxidize those thiol groups to disulfides intentionally, usually with mild oxidants in controlled pH, but the resulting forms lose most of their chelation punch. The sulfonic acid moiety resists hydrolysis under physiological conditions but can flex in certain redox reactions. Looking at the research, most chemical modifications focus on introducing alkyl or aryl substituents to improve selectivity or reduce toxicity. People working in organic synthesis sometimes push the dithiol group for click-chemistry or other couplings, chasing new polymers or diagnostic agents. The compound resists strong mineral acids and alkali, so storage issues almost never tie back to chemical instability, but rather to contamination or improper packaging.

Over the years, the compound gathered a list of names—DMPS, Unithiol, Dimaval, and sodium 2,3-dimercapto-1-propanesulfonate monohydrate. In industrial and clinical writing, Unithiol often pops up, especially where toxicity or chelation studies appear. Some suppliers stick with the IUPAC name, which confuses people outside pharmaceutical circles. Naming often reflects country and industry use. For example, Dimaval dominates in German literature, while Unithiol is frequent in clinical toxicology. Confusion from mislabeling or mixed naming standards seeped into a few regulatory filings I reviewed. Standardizing labels, particularly in multi-country studies, clears up mix-ups before they spiral.

Handing this substance, safety top-lines every protocol. Gloves, goggles, and fume hood work have become second nature in labs I worked in, not just for regulatory box-checking, but because we saw what happened after complacency. Short-term exposure can cause skin sensitization—itchiness or redness that lingers if left untreated. If someone accidentally inhaled powder, coughing and mild respiratory distress followed. Proper spill response includes neutralizing with wet wipes and immediate disposal—not leaving dust to circulate. Transportation follows strict guidelines: proper labeling and cushioning containers inside sturdy secondary containment. Waste management means collecting all residues for hazardous waste incineration and never tossing down the drain. Anyone storing this compound outside of recommended temperature finds clumped powder or, worse, containers fused shut from vapor buildup, a clear sign that proper storage isn’t optional.

The compound’s golden ticket comes from its use in chelation therapy, especially in cases involving mercury or lead poisoning. Medical professionals, especially in eastern Europe and some Asian countries, prescribe DMPS under controlled supervision, tracking kidney function and blood metal levels before, during, and after treatment. Environmental chemists turn to it for soil and groundwater cleanups, where other chelators struggle under high salinity or variable pH. In analytical chemistry, it improves detection limits by pulling trace metals out of complicated matrices. More recently, a few teams looked at its role in developing biosensors—those dithiol groups on the molecule’s backbone provide stable binding sites for metal-based signals. Despite all these uses, researchers monitor dosing tightly. Too much of a good chelator strips away essential metals in patients or disrupts nutrient cycles in bioremediation efforts. Regulatory paperwork for each of these applications eats up time, but overlooking these details leads to more harm than good.

For a compound that’s been around for decades, the R&D angle looks at both medical breakthroughs and environmental impact. As a bench scientist, I often wondered about the balance between efficacy and safety. Many groups ask—how does DMPS hold up against new chelators, or can it be delivered more selectively to affected tissues? Some trials in the late 2000s tested nanoparticle encapsulation, aiming to steer DMPS into deep tissue or across the blood-brain barrier, though most didn’t outperform the parent compound by much. Analytical labs experiment with DMPS in new sensor coatings, hoping to improve selectivity for metals like cadmium and gold. Its main drawback remains its ability to bind essential trace metals indiscriminately, so selective modifications are a hot ticket for safer use. Governments and grant agencies keep channeling resources into optimizing formulations, delivery methods, and application protocols, never satisfied by “good enough” for a substance used in living systems and natural environments.

People worry about chelators like DMPS stripping vital minerals along with toxic metals—concerns grounded in both animal and clinical studies. Acute exposure in lab animals causes mild renal stress at high doses, but chronic misuse explained most negative outcomes I’ve seen in published work. Human case studies highlight the need for careful supervision: improper self-medication, especially from over-the-counter imports, has led to severe hypokalemia and transient liver enzyme elevations. Long-term follow-ups in chelation patients show DMPS clears from blood relatively fast, with most adverse reactions stemming from dosing errors, pre-existing renal compromise, or unpredictable allergic reactions. Regulatory agencies maintain a cautious stance—requiring trials to closely monitor kidney function, electrolyte levels, and allergic reactions. Despite occasional online claims of miracle cures or “natural” heavy metal detox, real-world safety relies on medical supervision, meticulous follow-up, and hard limits on duration and dose.

Looking forward, interest in DMPS has swung beyond classic chelation therapy. The growth of urban mining—extracting metals from electronic waste—puts chelators at the center of green chemistry initiatives. Researchers in Asia and Europe are sizing up DMPS-based systems for selective recovery of precious metals, seeking to cut down on energy-intensive extraction. Medical innovation spins on, with scientists testing lower, split-dose regimens and combination therapies to reduce adverse effects while keeping enough punch to knock out heavy metal toxicity. Enhancing tissue specificity by tacking on peptide or nanoparticle “tags” stands out as a promising direction, though clinical approval remains years off at best. As environmental standards tighten, DMPS will likely keep a role in water purification and diagnostic testing. Whether new chelators appear or not, the monohydrate salt stands as both a benchmark and a backup—its practical track record earning a spot in safety protocols, regulatory frameworks, and scientific toolkits.

Dimercapto-1 propanesulfonic acid salt monohydrate drops right into a select group of chemicals that actually get the job done for heavy metal detox. Picture this: years ago, watching a lab scene, I saw scientists struggle with removing toxic metals from environmental samples. Regular washing didn’t do the trick. They needed something strong, reliable, something that could bond with metals and sweep them right out of complicated solutions. That’s where this chemical comes in—scientists turn to it because it latches onto metals like lead, mercury, and cadmium and pries them away from their hiding spots.

One story sticks with me, from a county in northern India where kids had high blood lead levels. Regular chelation medicines fell short, sometimes causing side effects nobody wanted. Toxicologists there started talking about Dimercapto-1 propanesulfonic acid derivatives. Turns out, this salt can bind with metals in the bloodstream and help the kidneys toss them out, all with a lower risk of damaging sensitive tissues compared to old-school chelation agents like British anti-Lewisite. The science backs this up, too. Peer-reviewed studies show it can lower body burdens of metal ions more efficiently and less painfully. For families in places haunted by mines or old industry, this kind of chemistry offers hope.

Pharmaceutical labs use this compound for more than just cleaning up people. Analytical chemists lean on it for sample preparation, scavenging traces of toxic metals before quality testing starts. Water treatment plants sometimes pull it off the shelf when heavy metal contamination spikes threaten supplies. None of this is theoretical. Environmental consultants bring it up in meetings because old methods for heavy metal reduction—like simple filtration or pH adjustment—don't always catch the worst offenders. By designing their strategy around chelation chemistry, companies actually deliver water that’s safer to drink, and regulators see the difference in the lab results.

Every chemical comes with responsibility. Dimercapto-1 propanesulfonic acid salt monohydrate doesn’t give a free pass. Trained staff still need to handle it with decent protective gear, proper ventilation, and a disposal plan that keeps residues out of natural waterways. I’ve watched teams slip up, thinking a “medicine” grade reagent meant low risk. The reality is: if this stuff bonds so effectively with metals in a test tube, it could do embarrassing things if mishandled in the wrong situation. So, safety training and clear labeling must go hand in hand with the advantages the compound brings.

Many regions ignore heavy metal exposure until the symptoms become obvious. Schools, food-packaging operations, and even some city water services rarely check for subtle buildups. If researchers and regulators shared what they learn from using dimercapto-1 propanesulfonic acid more widely, standards might rise. Investing in routine screening and better chelation protocols keeps people healthier and avoids bigger disasters. Once technology like this enters the conversation, it gets harder for anyone to claim ignorance about environmental risks that are sitting right in front of us.

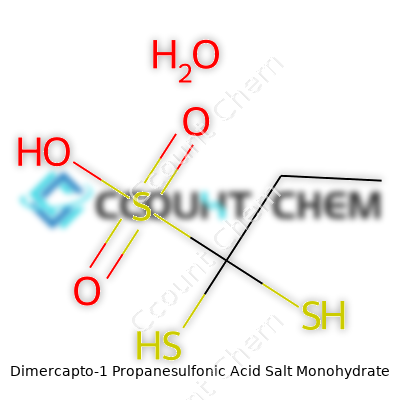

Understanding the nuts and bolts of a compound clears up confusion, cuts through marketing fluff, and often roots out myths found online. Let’s break it down for Dimercapto-1 Propanesulfonic Acid Salt Monohydrate. Chemists know this compound under the formula C3H7NaO4S3·H2O. Simple terms: carbon (C), hydrogen (H), sodium (Na), oxygen (O), sulfur (S), and a touch of water to give it the “monohydrate” tag. Precision matters here. Even the water counts in how the compound reacts, dissolves, or binds to metals.

Lab techs and researchers pay attention to molecular weights, and for good reason. For this compound, the molecular weight clocks in at about 246.28 g/mol. This isn’t random trivia. Picture trying to mix the right dose for a medical application or prepping a solution for heavy metal detox. One miscalculation leads to wasted time or worse—testing that fails, or even patient risk. This figure comes straight from the sum of each element’s atomic mass: triple carbon, seven hydrogens, a sodium, four oxygens, a trio of sulfurs, plus two more H’s and an O in that water molecule.

Plenty of folks treat chemical formulas like unimportant details, but I learned in the lab that forgetting a hydrate or swapping a sodium for a hydrogen dominoes into spoiled results. There are stories in chemistry forums where people share how a mix-up forced entire batches down the drain. Nobody likes that kind of waste—especially when budgets or reputations are on the line. Correct formulas prevent those headaches. Every gram added or dissolved needs clear math. In pharmaceutical circles, precision means safety for patients and compliance for manufacturers. Labs that cut corners or fail to check hydrates risk public safety and legal trouble. One missed water molecule and dosages drop out of spec, causing failures all the way down the line.

Dimercapto-1 Propanesulfonic Acid gets discussion in detox routines and water treatment. Its sulfur groups latch onto heavy metals, forming tight, less reactive complexes that get more easily excreted from the body or separated in industrial setups. The sodium salt version dissolves more easily, opening it up for use in water or biological tissues. Even there, the hydrate changes how quickly it dissolves and how much ends up in your end solution. Decisions on formula affect how much a patient gets or how much lands in a treatment tank.

Picking apart crowded information fields like chemical supply sites or published research always comes back to experience and sources. Reputable supply catalogs check every entry for accuracy. Working chemists double-check molecular weights and formulas—they have to. Papers and patents reference CAS numbers, supplier certificates, or databases like PubChem and ChemSpider. In my own career, I’ve flagged suppliers who used outdated or incomplete chemical notations, which caused procurement errors and project delays. As always, the small details end up mattering as much as the headline application.

Some mistakes come from confusing naming systems, missing hydrate tags, or language barriers in global trade. Coordinated education, easy-to-read safety data sheets, and standardized databases can prevent those small errors from turning into big problems. Directly listing complete formulas and weights on every container and in every digital reference makes sense—cut the clutter and drop the chance for mistakes. Training lab staff and even students to recognize when a hydrate or salt matters builds good habits from the start. Good data, smart checks, and teamwork make chemistry safer and more reliable for everyone who handles it.

Dimercapto-1 propanesulfonic acid salt monohydrate—let's call it DPSA for simplicity—comes with a reputation for sensitivity. This compound stands out for its application in chelation therapy, lab research, and heavy metal decontamination. Its molecular makeup tells us a story: moisture matters, temperature matters, and cross-contamination spells trouble. In experience, proper storage practices allow chemicals like DPSA to keep their structural integrity, effectiveness, and safety profile, day after day.

DPSA won’t play nice with excess heat. Warm, stuffy areas speed up chemical breakdown. Most researchers I know, myself included, found that a refrigerator—not a freezer—works best for short and long-term storage. Set the temperature between 2°C and 8°C. Freezing can damage the crystalline structure, and thawing may cause clumping or water absorption, which lowers its quality over time.

The monohydrate portion of DPSA signals water in its structure. Exposing it to humid air means more water gets in, sometimes altering its properties. Fumbling this step can cause a change in weight or appearance—something that's caught me off guard before. To prevent this, I always use tightly sealed glass bottles with PTFE-lined caps. Silica gel packets in storage cabinets absorb extra moisture, so DPSA stays stable even if the lab’s air conditioner falters. Storing DPSA in a desiccator is another method that works just as well.

Many forget that direct sunlight and even fluorescent lab lights can trigger slow breakdown in certain compounds. DPSA, sensitive by nature, should sit in dark amber bottles or at least in opaque, closed containers. Every old-school chemist swears by this, and their storerooms last the longest. Never store DPSA next to acids, bases, or oxidizers—spillage or fumes can stir up unwanted reactions. Hardened researchers often create separate shelves for high-value sulfur compounds like this, well away from ordinary stock chemicals.

Common sense goes a long way. Label every bottle with the open date, operator’s initials, and concentration or batch info. Doing this avoids confusion during audits. Any experienced chemist knows unlabeled containers fuel accidents, especially when years separate the initial project and a follow-up. Every few months, I run a quick inventory, checking for crystals, clumps, or color change—and responsible labs do the same.

Safety standards, not shortcuts, give peace of mind. Institutions set tough rules for handling and disposal, and for good reason: DPSA’s thiol groups catch metals in the body or the environment, but that same reactivity causes havoc if spilled. Emergency eyewash and spill kits should stay within arm’s reach. Manual weighing and transferring away from vents or strong air currents avoids the risk of losing material into the air. Always wear gloves, goggles, and a lab coat before touching DPSA—my hands remember the sting of carelessness.

Safe storage for DPSA depends on respect for detail. Cold, dry, dark, and isolated—those four words sum up years of experience. Follow them, and you won't waste research-grade material, or worse, endanger lives. In my field, a careful storage plan pays off tenfold, and it sets the tone for safe, reliable science everywhere.

Dimercapto-1 propanesulfonic acid salt monohydrate, sometimes shortened to DMPS, gets used in chelation therapy and scientific laboratories. It attracts interest, especially from those handling toxic heavy metals like mercury, lead, or arsenic, since it binds to these metals and helps the body shed them. Chemists appreciate its water-solubility and the way it encourages metals to leave tissues. I’ve seen researchers treat this compound with respect and keep it in restricted storage areas.

Many scientists view DMPS as a valuable tool, but that doesn’t mean it’s free from risks. In medicine, it belongs to a class of drugs called chelators, which doctors sometimes prescribe to patients suffering from heavy metal poisoning. Its strength comes from its ability to form tight complexes with metal ions, but this same action can strip away other important metals if handled carelessly. That’s why clinical settings monitor people closely if it’s given as a treatment. Overuse can lead to mineral imbalances and trouble for the kidneys.

Regulatory bodies treat DMPS as a hazardous substance, especially before it’s diluted or administered under supervision. Researchers have documented that DMPS powder can irritate eyes, skin, and mucous membranes. If inhaled or swallowed in concentrated form, it may cause nausea, dizziness, and more severe symptoms if exposure continues. Some lab safety data sheets recommend full-face protection, gloves, and working with DMPS inside a chemical fume hood, which highlights the respect it gets from people familiar with its hazards.

As a worker who’s spent time in both the pharmaceutical and research fields, I put a lot of weight behind personal protective equipment and training. I’ve witnessed how a slip — an uncovered spill or an inattentive moment — leads to lab evacuations or serious incidents. DMPS falls into the same category as many lab reagents, so best practices should never get taken for granted.

Proper handling requires ongoing education. Too many professionals underestimate the risks until they see a real accident—or, even worse, become involved in one. Limiting airborne dust by using sealed containers makes a difference. Spill kits and clear labeling cut down confusion during a tense cleanup. Wash stations near work areas also matter more than most people realize.

One crucial solution I’ve seen work time and again: education before access. Anyone who comes near DMPS in raw or processed form should learn its chemical hazards, not just the benefits. Hands-on training, not online quizzes or a quick slide deck, builds respect for compounds like this. Institutions that tie hands-on safety drills to chemical access keep their record cleaner and their teams healthier.

Disposal matters just as much as storage and handling. DMPS doesn’t belong in regular trash or down a sink. Environmental releases could lead to contamination of water systems, harming wildlife and, eventually, people. Communities that rely on public water sources shouldn’t have to wonder what’s drifting downstream from a local research center or clinic. I’ve seen waste management teams triple-check records for DMPS, and that extra step carries weight in keeping neighborhoods safer.

The story of DMPS can’t be summed up with a simple yes or no answer to the question of toxicity. It all comes down to context—dose, exposure, training, and environmental stewardship. Science offers a clear message: treating chelators with respect avoids the worst outcomes. Too much certainty leads people to overlook dangers, but honest, open conversations about chemistries like DMPS save lives.

Dimercapto-1 propanesulfonic acid salt monohydrate looks like a mouthful on paper. In the lab, it’s a solid that helps pull heavy metals from solutions or living systems. I’ve had days standing at a bench, puzzled by a jar of something like this, flipping the Safety Data Sheet, wondering what’s the cleanest path from powder to solution. I’ve learned a thing or two from old heads and the rare buried guidance document. The steps might seem fussy the first time, but it all comes down to chemistry’s basics: dissolve it right, measure carefully, keep it clean.

No matter how fancy or obscure the salt, water usually does the trick. This one follows the trend — it dissolves well in pure, room-temperature water. Skip the coffee mug; always measure your powder in a dedicated weigh boat, then gently tip it into a beaker. Cold water works, but I noticed, especially on chilly winter mornings, the stuff dissolves a bit slower. Warm the water to room temperature — but don’t use hot or boiling water, since some sulfur-containing chemicals break down with too much heat. Stick with deionized or distilled water. Tap water is unpredictable: minerals and chlorine often skew experiments and can even create new, unwanted compounds.

I’ve watched people dump a whole mass of powder into water and expect clear solution in seconds. It doesn’t work that way. Sprinkle the powder in slowly. Use a glass rod or a magnetic stir bar to help it along. Rapid stirring or shaking beats clumps. This salt dissolves quickly, but if you spot any stubborn bits after a few minutes, let it sit and stir longer. Be patient. In my experience, this process usually only takes five to ten minutes with gentle stirring. Don’t rush with aggressive shaking; you just splash or bubble air into the mix.

Getting the right concentration matters, especially if you’re running anything related to toxicity, chelation, or analytic chemistry. Use a calibrated analytical balance. Don’t eyeball it — weigh your sample to the nearest milligram. Accurately measure water volume in a class-A volumetric flask if you’re prepping standard solutions. For normal daily use, graduate cylinders work, but errors stack up quickly if you start cutting corners.

Dimercapto compounds can be picky about pH. Solutions hold up better around neutral pH; below pH 4 or above pH 8, degradation picks up. I’ve used portable pH meters to double-check, then tweak with sodium hydroxide or hydrochloric acid in tiny amounts. Many labs use phosphate buffer at pH 7 to keep things steady, especially if the solution sits for hours or days. I learned the hard way it’s best to prepare just what’s needed each day instead of stockpiling a big batch. Light, heat, and exposure to air can slowly knock out some of the chemical action.

Once prepared, pour your solution into glass or high-quality polypropylene containers. Label it fully — name, date, concentration, and your initials. Store in a cool, dark refrigerator if you plan to keep it overnight. The bottle needs a tight cap; sulfur odors and air make a poor combination for stability and for the way your lab smells next morning. In busy labs, I’ve seen folks leave solutions out at room temperature, only to find a mystery cloud in the flask a week later. Cool and dark buys you time; exposure throws your work off course. If in doubt, mix up a fresh batch and jot down any changes you spot. That record has saved more than one project on deadline week.

| Names | |

| Preferred IUPAC name | Sodium 3-sulfanyl-2-sulfanylpropane-1-sulfonate monohydrate |

| Other names |

3-Mercapto-1-propanesulfonic acid sodium salt monohydrate Sodium 3-mercapto-1-propanesulfonate monohydrate MPSA sodium salt monohydrate SPS monohydrate Sodium salt of 3-mercapto-1-propanesulfonic acid monohydrate |

| Pronunciation | /daɪˌmɜːr.kæpˈtoʊ wʌn ˌproʊˌpeɪnˈsʌl.fə.nɪk ˈæs.ɪd sɔlt ˌmɒn.oʊˈhaɪ.dreɪt/ |

| Identifiers | |

| CAS Number | 17636-10-1 |

| Beilstein Reference | 3914832 |

| ChEBI | CHEBI:131378 |

| ChEMBL | CHEMBL2106017 |

| ChemSpider | 22995909 |

| DrugBank | DB09161 |

| ECHA InfoCard | 03d8560c-8e33-4517-94eb-8ebf801c1e9c |

| EC Number | 'EC Number: 251-448-6' |

| Gmelin Reference | 82834 |

| KEGG | C19699 |

| MeSH | D013964 |

| PubChem CID | 16137320 |

| RTECS number | WN7356000 |

| UNII | 6T4978U17Z |

| UN number | UN3335 |

| Properties | |

| Chemical formula | C3H7O4S3Na·H2O |

| Molar mass | 208.30 g/mol |

| Appearance | White to off-white powder |

| Odor | Characteristic |

| Density | 1.56 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -4.3 |

| Acidity (pKa) | 9.62 |

| Basicity (pKb) | 8.10 |

| Magnetic susceptibility (χ) | -7.36e-6 cm³/mol |

| Refractive index (nD) | 1.570 |

| Dipole moment | 6.2 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 220.6 J·mol⁻¹·K⁻¹ |

| Pharmacology | |

| ATC code | V03AB33 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302+H332: Harmful if swallowed or if inhaled. |

| Precautionary statements | P264, P270, P273, P280, P301+P312, P330, P391, P501 |

| NFPA 704 (fire diamond) | 1-0-0 |

| Flash point | > 97.8°C |

| Lethal dose or concentration | LD50 Rat oral 891 mg/kg |

| LD50 (median dose) | LD50 (median dose): > 2,000 mg/kg (oral, rat) |

| NIOSH | WFH40930SP |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.01 mg/m³ |

| Related compounds | |

| Related compounds |

Dimercaptosuccinic acid Dimercaprol Unithiol (DMPS) Penicillamine Meso-2,3-dimercaptosuccinic acid Mercaptosuccinic acid |