Chemistry rarely stands still, and few compounds show this better than calcium dodecylbenzenesulphonate. Surfactants gained serious attention around the midway point of the twentieth century. With the boom in synthetic detergents, scientists directed real energy toward replacing natural soaps, which often struggled with hard water. Lab experiments started mixing dodecylbenzene with sulfur trioxide, then neutralized it with calcium salts instead of sodium. These tweaks, once laboratory curiosities, encouraged manufacturers to scale up production for industry uses. Companies like BASF and Stepan pushed for cleaner, cheaper, and safer routes, learning from trial, error, and mountains of field feedback. It took several decades to iron out problems with supply purity, shelf life, and environmental impact, but the early inventiveness set the stage for a substance that continues to prove its value in industries that touch most parts of modern life.

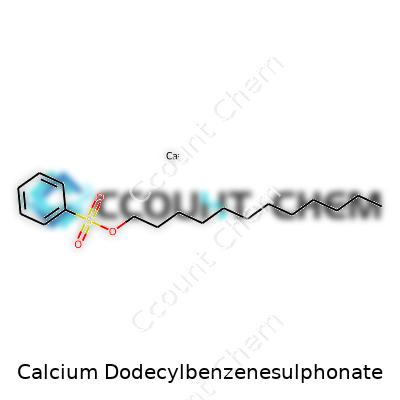

This surfactant forms the backbone of many cleaning and emulsifying systems. Its structure—a long dodecyl chain attached to a benzene ring, sulphonated and bonded with a calcium ion—offers useful traits. Unlike sodium versions, this form produces less foam and better stability in hard water conditions. The industry uses it as a wetting agent, emulsifier, and detergent, especially where calcium’s lower solubility brings process benefits. In my own lab work, I’ve seen it lock up impurities that can wreck sensitive coatings or clog up machinery, and it plays a key role in industrial and household products where consistent performance matters for quality and safety. Reliable batch-to-batch purity defines utility in such uses, and decades of quality control have improved trust from both technical specialists and regulatory agencies.

Calcium dodecylbenzenesulphonate appears as a pale, creamy powder or off-white granule, sometimes a viscous liquid if formulated for special uses. Its distinct, soapy smell lingers in storage rooms, but that doesn’t last in formulations where perfumes mask the base note. The compound does not dissolve easily in cold water, producing a milky suspension instead of a clear solution. Heating brings moderate solubility, but it's the emulsification rather than the dissolution that manufacturers really chase. This salt holds up in acidic environments and resists breaking down under harsh mechanical stress, reason enough for its popularity in tough, real-world applications. Chemists appreciate its predictable behavior across temperature swings and its respectable shelf stability, which stretches for months or even years in sealed containers away from damp.

Labelling rules and tech specs trace their roots to years of customer complaints and operational mishaps. A typical label lists purity, often over 90%, plus moisture content and any notable byproducts such as free acid content. An effective product needs calcium dodecylbenzenesulphonate content tightly controlled, which usually falls between 60 to 95%, depending on blend or formulation. Impurities matter, with limits for residual organics and heavy metals. Particle size—an underappreciated detail—affects mixing with other powders in automated feeders or during storage. Data sheets now carry clear hazard symbols, safety phrases, and handling requirements, bridging the gap between chemist and factory worker. Batch numbers, manufacture dates, and shelf-life projections invite traceability, which helps prevent costly recalls and compliance headaches.

Producing calcium dodecylbenzenesulphonate is more than simple mixing. The main synthesis starts by sulphonating dodecylbenzene with an agent like sulfur trioxide or oleum. That reaction produces dodecylbenzenesulfonic acid. Chemists neutralize this with calcium hydroxide or calcium oxide. Precision controls at this step impact yield and purity; too little base leaves acidic residues, too much locks up unreacted materials. Filtration and drying separate granular products from the wet mass, and, for liquids, vacuum dehydration removes excess water. Operations scale from pilot batches to tank farms, but strict equipment cleaning practices matter at every size. My time running small-scale batches taught me how minor temperature or pH drifts could shift output from smooth grain to unpredictable clumps, which can jam process equipment or produce hazy finished goods. The best operators troubleshoot on the fly, always watching viscosity and particle uniformity.

Chemical flexibility defines this compound’s utility. Sulphonation reactions provide the initial backbone, while post-treatments let technicians modify chain length or tailor the aromatic ring for special needs. Reacting the sulphonate with different metal salts (not just calcium) creates blends for labs to test water resistance, foaming, or viscosity. Oxidation can tweak side chains to reduce unwanted byproducts, lowering eco-tox risks. Chemical engineers in the detergent, oil, and agriculture sectors often experiment with co-formulations, pairing calcium dodecylbenzenesulphonate with nonionic surfactants to punch up performance on oily soils or boost sprayability. Lab chemists have even grafted new functional groups onto the ring structure, scouting for green chemistry pathways using recycled feedstocks or lower-energy routes. Timely research publications lay out newly patented processes for improving performance or cutting process costs, often building on the base chemistry of sulfonation.

Depending on where and how it’s sold, calcium dodecylbenzenesulphonate picks up a long list of aliases. Industrial buyers might find it under names like "Calcium alkylbenzene sulfonate", "Calcium salt of sulfonated dodecylbenzene", or manufacturer brands such as "Petrostep CaBLS". Trade magazines and technical catalogues may use the short-code "CaDBS". These product names sometimes reflect slight specification tweaks—differences in chain length, dryness, or additive blend—so my advice to newcomers is always to check the manufacturer’s data sheets before assuming compatibility. This avoids confusion that can arise in procurement, especially when customer specs ride on a razor’s edge.

Operational safety has improved by learning from past mishaps. Spillages on warehouse floors bring slip hazards, so plants adopted proper spill containment mats and improved forklift training. Dust control became crucial once health officers noticed workers coughing after long exposure; modern plants install dust extractors and require personal protective equipment. The global adoption of industry safety norms, like OSHA in the US or REACH in Europe, forced tighter labeling, training, and workplace ventilation for compounds like this. Its moderate skin and eye irritant properties prompt gloves and goggles, while high temperatures generate fumes that need proper exhaust systems. Emergency protocols hang on walls in most mixing rooms where this powder shows up, and seasoned operators respect the risks, especially on clean-down days when residues build up on equipment. I’ve seen firsthand how routine strictness in housekeeping prevents not only injuries but also expensive downtime.

Farmers rely on it as an adjuvant, helping pesticide sprays cut through waxy leaves. In the oil sector, rigs call on the compound’s emulsifying muscle to keep drilling muds working under harsh underground pressure. The textile industry turns to it for scouring raw fibers, stripping away greasy residues so dyes bond as intended. Powder and liquid detergents harness its cleaning punch, especially for tough soils on workshop uniforms or industrial tools. Asphalt plants use it to bind and stabilize sticky road mixes, keeping dust down as highways and runways stretch across continents. I’ve witnessed maintenance teams grateful for its water resistance. These applications are far from trivial; they help keep infrastructure cleaner, food safer, and supply chains sturdy in the face of wild weather or unpredictable demand surges.

The science doesn’t slow down. Research labs spend years searching for more sustainable production methods, from green sulphonation chemistries to using recycled feedstocks. Academic-industrial partnerships push for formulations that biodegrade faster, answering society’s call for less ecotoxicity and cleaner effluents. Multinational corporations invest in smart sensors to monitor particle size or detect trace impurities in real time, squeezing efficiencies from every ton produced. Researchers keep probing the molecule’s interactions with other surfactants, searching for performance synergies or new cleaning breakthroughs. Global literature tracks enzyme modifications, biosurfactant hybrids, and safer substitute chemistries, but calcium dodecylbenzenesulphonate remains a workhorse that plenty of R&D teams come back to after stretching the envelope with less proven alternates.

Years of study have dug deep into its health and environmental impact. Toxicologists ran many cell and animal studies. Results show low acute oral and dermal toxicity, but that doesn’t grant a free pass for careless use. Repeated contact dries out skin and triggers irritation. Inhalation of dusts and mists remains risky, especially in closed mixing rooms. Environmental scientists found it breaks down more slowly in cold or salty water, sparking concern where effluents reach sensitive rivers or lakes. Regulatory tests assess persistence and potential to bioaccumulate, and eco-labelling requires rigorous data from certified labs. Researchers in my circles discuss evolving test protocols using aquatic species, which sometimes yield conflicting results that force a rethink of allowable use rates or disposal practices. Transparency in this research builds public trust that matters when products touch food and water.

In the next phase, industry will see even more demand for greener options and better traceability. Synthetic chemists are designing new sulfonation catalysts that waste less sulfur. Water-soluble versions could open new markets in personal care, where gentle skin feel is prized. Waste recycling could see old detergent stocks reprocessed into industrial cleansers or road additives, leveraging circular economy principles. Digital manufacturing systems promise fewer batch errors and tighter quality, all but eliminating the waste that dogged the last century’s operations. Frontline technicians—people who once cursed every unplanned shutdown—will see safer workspaces as sensors, automated sampling, and connected supply chains improve predictability and reduce spills. Science marches on, and so does the need for practical, scalable, responsible chemistry that balances performance with planet.

Step into a typical hardware store or glance under your kitchen sink. Most people probably never notice the complicated ingredients in those cleaners or detergents. One of those hard-to-read names, calcium dodecylbenzenesulphonate, plays a major behind-the-scenes role in all sorts of products that touch daily life. It doesn’t draw headlines or appear in clever ad campaigns, but it keeps everything from floors to farm fields cleaner and better protected.

A product made to clean cars, greasy engine parts, or dirty work uniforms often packs in calcium dodecylbenzenesulphonate. This strong surfactant has the rare ability to break apart oils and dirt that water alone shrugs off. Think about scrubbing a stovetop after frying—grease clings stubbornly unless a detergent cuts through it. This molecule tackles those fats by breaking them into smaller pieces, letting them rinse away. Because it does not break down quickly in hard water, people rely on it everywhere from coin laundromats to truck stops.

Dust rising off fields, chemical run-off, and patchy growth in crops have challenged farmers since the start of modern agriculture. Many folks do not realize that sprayable herbicides, fungicides, and fertilizers aren’t as simple as “add water and go.” They need an extra push to stick to leaves or soil and penetrate plant surfaces. Here, calcium dodecylbenzenesulphonate steps in as a wetting agent. It spreads water-based chemicals more evenly across everything from lettuce to wheat stalks, meaning less wasted spray and more healthy crops. Research out of top agricultural colleges backs this up—yields improved where the right surfactants carried treatments onto every leaf.

Industrial cleaning teams choose this compound when tackling some of the dirtiest jobs. It keeps dust down at construction sites and mines, reducing health hazards for workers. It also keeps cooling systems in power plants or large-scale factories free from gunk and mineral build-up. Its presence helps sidestep bigger issues, such as cooling failures or costly shutdowns. In paints, it keeps pigments dispersed evenly so that professionals can depend on a smooth coat. Based on yearly chemical sales, thousands of factories across the world rely on this ingredient to deliver results both cheaply and effectively.

Most people, including myself, worry about how such chemistry drains into rivers or lingers on hands. The facts tell us that calcium dodecylbenzenesulphonate can harm aquatic life when not managed right. Environmental researchers have shown that runoff in urban areas, especially near car washes or big laundries, raises risks for fish and water bugs. Scientists and regulators push for tighter controls and lower-impact options. Some companies already use plant-derived surfactants or smarter wastewater systems. New policies from agencies like the EPA require better disclosures and safer handling. All this means people can still get things clean—just with a sharper eye on the bigger environmental picture.

Calcium dodecylbenzenesulphonate pops up in everything from laundry detergent to pesticides. Plenty of farmers and cleaning companies trust this stuff to break up grease and help mix powders with water. It helps coatings and plastics come together and stops particles from separating out in crop sprays. Its footprint travels past the farm gate, heading straight for our soil and water every time we mop floors, wash clothes, and treat fields.

I grew up helping my parents cultivate tomatoes, and I remember the runoff flowing into the stream behind our house each spring. Surfactants like calcium dodecylbenzenesulphonate don’t just disappear; residue sticks around. Studies out of the EU show some forms carry moderate persistence, meaning they stay in soil and water longer than many think. The tough benzene ring in its structure resists breaking down. Frogs downstream and worms underground soak up more than a quick taste. Non-target plants may also struggle when residues build up in irrigation systems.

Fish and invertebrates bear the brunt of runoff. The US EPA notes that calcium dodecylbenzenesulphonate causes acute toxicity for water fleas and fish at higher concentrations. Soap bubbles on a creek might not seem like much, but they’re a sign that surface tension is breaking. That’s trouble for gill-breathing creatures. They gulp water for oxygen through delicate membranes—add enough surfactant and membranes weaken, making survival harder. This chemical also speeds up the leaching of other toxins into groundwater, compounding the problem.

Regulators like the FDA approve calcium dodecylbenzenesulphonate in small amounts for food processing and cleaning. Most of us probably never worry about it in soap or cleaner. Yet, the same dose that feels “safe” to people can hammer tiny life forms that make up the base of the food chain. Once these effects stack up in streams and ponds, bigger species—herons, turtles, even humans downstream—face ecosystem fallout. Research by the World Health Organization flags bioaccumulation and toxicity in aquatic food webs where concentrations persist.

Watching how my old hometown cleaned its lake, I realized real change starts with good habits. Reducing overuse makes an impact. Farmers benefit from precision spraying that cuts down runoff. Homeowners swapping to true eco-friendly cleaners limit what flows down the drain. Municipal filter systems, especially those with activated carbon, grab more surfactants before water re-enters rivers. Regulations matter too. The EU’s REACH framework and California’s Prop 65 drive companies to test and report what’s in products.

Green chemistry keeps moving forward. Some companies now turn to plant-based surfactants. They break down quicker in nature, helping protect soil and streams. These innovations won’t cure everything overnight; old chemicals linger and habits die hard. Still, small efforts in homes, businesses, and policy set up a path toward less pollution.

My experience in both rural and city environments has shown that safety for us doesn’t always mean safety for the environment. Paying closer attention to labels, pushing for smarter regulations, and supporting better product design all help tip the balance. The clean water we count on tomorrow depends on the decisions we make today—not just in government labs, but in the detergents we buy and the routines we follow at home and on the farm.

Calcium dodecylbenzenesulphonate gets plenty of use by companies making cleaning products. Think laundry powders, industrial degreasers, and even dishwasher soaps. It’s prized as a surfactant—essentially, it breaks down grime, lifts oil, and helps water wash it all away. Before working in tech, I spent a couple of months with a local janitorial supplier. Their warehouse brimmed with fifty-pound bags of soapy chemicals, and labels often listed this calcium compound. This ingredient lets cleaning agents bubble up in hard water, making it easier for factories, hotels, and schools to get sparkling results even when their tap water runs chalky.

Farms and landscaping outfits rely on this calcium salt in their pesticide and herbicide mixes. Spray drift and uneven application can waste chemicals and leave weeds or insects behind. I grew up in a farming community where everyone had a different approach to crop care. Many agri-businesses added specialized surfactants directly to their sprayers. Calcium dodecylbenzenesulphonate helped keep plant treatments even and persistent, which meant less runoff and more control over pests. According to research by the International Crop Science Journal, surfactants like this improve the sticking and spreading of active ingredients, so fields see fewer passes and healthier yields.

Every metalworker faces problems with overheating or chattering bits. Factories that manufacture parts for cars or appliances add calcium dodecylbenzenesulphonate to their cooling and lubricating fluids. This ingredient keeps oil and water working together, reducing friction between blade and metal. A friend who manages a machine shop explained how a stable emulsion means tools last longer and cut cleaner, which helps everyone on the floor meet tough production deadlines. There’s also less toxic smoke or slippery residue collecting on walkways, so workplaces stay safer.

Anyone who’s watched a contractor pour concrete in rainy weather has seen admixtures in action. Builders add this calcium-based surfactant to concrete and mortar. It helps plasticize the mix, reducing the amount of water needed and improving workability. The result is a smoother pour, fewer cracks as it cures, and better durability against freeze-thaw cycles. Construction teams no longer fret as much about their raw materials clumping or resisting the trowel, because this additive makes the sludge flow more like cream and harden with fewer surprises.

Demand for greener, safer chemicals keeps rising in all these industries. Some research groups in the EU and US pursue plant-based or biodegradable surfactants to replace the petroleum-based kind, including alternatives to dodecylbenzenesulphonate. Trials with coconut oil- and sugar-based surfactants have started to appear in cleaning products and agri-chemicals, but matching the toughness and cost of older surfactants remains a work in progress. It’s clear that companies open to testing new blends will be ahead of the curve, both in protecting workers and meeting tougher chemical safety rules.

Calcium dodecylbenzenesulphonate often pops up in detergents, pesticides, and a range of cleaning agents. This ingredient breaks surface tension and helps things mix, much like how adding dish soap makes greasy pans easier to scrub. This surfactant holds a steady spot in chemical blends, not by accident, but through years of lab testing and real-world performance.

In most cases, the concentration of calcium dodecylbenzenesulphonate falls between 1% and 8% by weight in liquid cleaners, with common home dish soaps hovering in the 2–4% range. The higher end, such as 5–8%, turns up in heavy-duty cleaners or industrial applications like degreasers and certain agricultural sprays.

Pesticide formulations push those numbers closer to 10%, since robust wetting and spreading on plant surfaces matter. These aren’t secret numbers. They come from public safety data, regulatory filings, and well-established formulation handbooks.

Years ago, I helped reformulate a farm cleaner for a small poultry operation. We started with a generic recipe and dialed the surfactant load up and down until the results matched the messy reality of a chicken barn. Adding a little too much didn’t just foam more; it made rinsing tough, which frustrated the workers and wasted water.

At low doses, the cleaning flopped. Nothing loosened the grime, so labor costs soared. The “right” dose came from hands-on testing, not just a number in a book. Most chemistry jobs run like this—numbers combined with actual user feedback.

Regulators and safety experts set ceiling limits so runoff doesn’t damage waterways or soil health. That’s another reason precise dosing matters. The European Chemicals Agency and US EPA both back up their rules with hard data on skin irritation, aquatic toxicity, and breakdown rates.

Mess up the ratios and you can deal with persistent residue, possible side effects for skin, or unnecessary environmental impact. Typical doses straddle the line between getting the job done and steering clear of health or environmental trouble.

Instead of overloading detergent bases, it’s smarter to pull in co-surfactants or alternate boosters. Manufacturers now experiment with blends—think fatty alcohol ethoxylates or enzymes—to maintain cleaning muscle without ballooning the surfactant load.

Reformulation sometimes stirs complaints about cost. The push for greener labels and more sustainable products causes brands to revisit their surfactant choices. Calcium dodecylbenzenesulphonate can still play a role, but many producers now include biodegradable partners to lighten the environmental footprint.

In most real-world settings, you’ll find 1–8% used as a guide. Field testing, environmental checks, and worker comfort finish the job that lab numbers start. No two applications look identical, but a focus on safety, real cleaning power, and new ingredient tech helps experienced formulators strike a steady balance.

Growing up with a parent in the chemical industry left me with early lessons about respecting what you touch. It doesn’t matter how mild a surfactant might look on paper — one error can lead to a world of pain or a ruined day for those around you. Calcium Dodecylbenzenesulphonate, often used in cleaning products or in some industrial degreasers, fits that picture. This chemical keeps oil and water from fighting with each other, but it won’t hesitate to cause skin and eye trouble if treated carelessly.

Direct contact irritates skin and eyes. After a busy afternoon mixing soap bases for a workshop, a distracted approach left a coworker with red hands and an angry rash. Washing up took care of it, but medical research backs this up: surfactant exposure tears up the skin barrier and does more damage after repeated contact. Inhalation isn’t friendly either. In powder form, the dust can sneak into airways, leaving you coughing or with a sore throat. Eyes hate it, too. Any splash sends you to the eyewash station. The MSDS from multiple manufacturers list these same warnings loud and clear.

Many think gloves look dramatic, but they do keep surfactants from settling into the skin. Nitrile gloves hold up well, and lab coats or long sleeves stop the irritation from spreading further. Safety goggles cost little and prevent run-ins with caustic residues. Plenty of industrial workplaces keep face shields handy, especially if splashing can’t be avoided.

Nothing replaces good airflow in a laboratory or factory. Old workshops with stuffy air leave dust and vapors hanging around, making it easier to breathe in particles without noticing. Local exhaust fans pull the worst of these away before they collect. Spill kits, absorbent pads, and neutralizing agents help with the (inevitable) accident. Once a friend forgot to clean a splash, only to find the area slick days later — a solid reminder that cleanup should always happen sooner, not later.

Mixing containers need big, clear labels. Color codes help, too. Training isn't just for new hires — even seasoned workers benefit from quick run-throughs on dealing with chemical safety. “Complacency” sums up most accidents I’ve seen. One shortcut, one faded label, and suddenly the wrong material goes into the wrong drain or container. Good habits save headaches down the line.

Pouring leftover solutions into a sink can poison more than just a sewer pipe. Local rules for hazardous waste exist for a reason: they protect workers, neighbors, and the water supply. Containers holding surfactant residue belong in dedicated waste bins. Waste manifests make tracking easy, and regular pickups by certified disposal services keep storage from getting out of hand.

Handling Calcium Dodecylbenzenesulphonate without care sets the stage for health problems or environmental messes. Personal protective equipment, good ventilation, strong labeling, and steady training are easy to overlook but make all the difference. The trouble with shortcuts? They rarely save time in the end. Experience says once you learn respect for a chemical like this, you never want to learn it the hard way twice.

| Names | |

| Preferred IUPAC name | calcium 4-dodecylbenzenesulfonate |

| Other names |

Calcium dodecylbenzenesulfonate Calcium dodecylbenzenesulphonate Benzenesulfonic acid, dodecyl-, calcium salt Calcium alkylbenzenesulfonate Calcium didodecylbenzenesulfonate |

| Pronunciation | /ˈkæl.si.əm doʊˌdɛs.ɪlˌbɛnˈziːnˌsʌl.fəˌneɪt/ |

| Identifiers | |

| CAS Number | 26264-06-2 |

| Beilstein Reference | 2205165 |

| ChEBI | CHEBI:34777 |

| ChEMBL | CHEMBL2204880 |

| ChemSpider | 21171317 |

| DrugBank | DB11221 |

| ECHA InfoCard | 03-2119480763-44-0000 |

| EC Number | 262-372-1 |

| Gmelin Reference | 85798 |

| KEGG | C01833 |

| MeSH | Dodecylbenzenesulfonates |

| PubChem CID | 24860665 |

| RTECS number | PM3625000 |

| UNII | Y3R92F8FP4 |

| UN number | UN3264 |

| CompTox Dashboard (EPA) | UFC000018 |

| Properties | |

| Chemical formula | C36H58CaO6S2 |

| Molar mass | 419.62 g/mol |

| Appearance | White to yellowish powder or flakes |

| Odor | Slight characteristic odor |

| Density | 1.1 g/cm³ |

| Solubility in water | Slightly soluble in water |

| log P | 5.9 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 7.5 |

| Basicity (pKb) | 11.96 |

| Magnetic susceptibility (χ) | -6.2e-6 |

| Refractive index (nD) | 1.10 |

| Viscosity | Viscous liquid |

| Dipole moment | 3.2 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | “465.2 J·mol⁻¹·K⁻¹” |

| Std enthalpy of formation (ΔfH⦵298) | -907 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -7797 kJ/mol |

| Pharmacology | |

| ATC code | QJQG50 |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. |

| GHS labelling | GHS07, GHS05 |

| Pictograms | GHS05, GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H318, H335 |

| Precautionary statements | P264, P280, P301+P312, P305+P351+P338, P337+P313, P501 |

| NFPA 704 (fire diamond) | 3-1-0 |

| Flash point | > 170°C |

| Autoignition temperature | > 400°C |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD₅₀ (oral, rat): 438 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 1,080 mg/kg |

| NIOSH | DSG5930000 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | REL (Recommended Exposure Limit) of Calcium Dodecylbenzenesulphonate is "5 mg/m³". |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Sodium dodecylbenzenesulfonate Ammonium dodecylbenzenesulfonate Magnesium dodecylbenzenesulfonate Potassium dodecylbenzenesulfonate Calcium alkylbenzenesulfonate |