Back in the industrial golden age, as dyes, pharmaceuticals, and advanced materials took center stage, chemists needed intermediates with reliability and reactivity. 3-Nitrobenzene sulfonic acid sodium salt turned up as one of those workhorse compounds. Its early production ramped up during the rise of synthetic dyes, as manufacturers recognized that it offered a robust scaffold for building azo and triphenylmethane dyes. Industrial uses kept expanding, especially in Central Europe and the US, fueled by growth in organic synthesis and improvements in sulfonation and nitration techniques. Researchers kept pushing methods to boost yields and lower waste, reflecting the industry’s knack for refining chemical manufacturing, often out of necessity when demand for cleaner and more selective reactions soared.

On the shelf, 3-nitrobenzene sulfonic acid sodium salt takes shape as a pale yellow or luminous orange crystalline powder. It’s hard to miss in a lab due to its signature tint, a calling card of the nitro aromatic family. Technicians reach for it thanks to its water solubility and predictable participation in substitution reactions. Beyond dyes, this chemical earns its keep as a dispersion agent, an intermediate for pharmaceuticals, and even a specialty additive in some electroplating solutions. Its stability and reactivity, once a bonus for dyestuff makers, now attract polymer, coatings, and specialty chemical manufacturers who need a versatile building block.

Take a look at the physical stats: this sodium salt ticks boxes for solubility, melting point, and stability. The compound holds together as a solid at room temperature, usually showing a melting range above 300°C, typical for aromatic sulfonates. Its sodium content bumps up its water compatibility, making it more attractive than the free acid. The material gives off no strong aroma, but the nitro group commands respect for its heft in redox chemistry. As for storage, it handles long-term shelving if kept dry and shaded; moisture or strong acids can skew its content and impact reactivity in later processes.

Quality control teams scrutinize specs like purity, water content, sodium equivalency, and the level of residual organic starting material. Laboratories demand consistent particle size if precise dosing is needed for batch processes. The labeling on high-grade batches spells out parameters—assay (typically ≥ 98%), moisture content (kept below 1.5%), sodium percentage, and sometimes the method used for quantification. Bulk drums get hazard statements, batch numbers, and handling directions. Every label underlines that this is both a workhorse intermediate and a regulated substance—handling instructions reflect a long tradition of process safety.

Producers often take the tried-and-true route: direct sulfonation of nitrobenzene with fuming sulfuric acid, followed by neutralization with sodium carbonate or hydroxide. This routes through exothermic steps needing strict temperature control—a misstep leads to byproducts and lost yield. Large-scale runs use glass-lined or stainless reactors for corrosion resistance. Some engineers explore greener sulfonation by recycling acid or controlling stoichiometry more tightly, which both saves feedstock and cuts the sulfate waste that used to fill old chemical plant scrap yards. Technicians take pride in finding that sweet spot of reaction time and heat management, knowing that consistency in the batch determines downstream product quality.

Once synthesized, this compound opens up both nitro and sulfonic groups for clever transformations. Reduction of the nitro group uncovers amines, paving the way for dye coupling or advanced pharmaceutical syntheses. Chemists sometimes use it as a pivot point for substitution, introducing other functional groups selectively and building more complex molecules. The sulfonic acid’s presence guides regioselectivity, letting researchers tweak the aromatic ring for targeted applications. In labs, the sodium salt version streamlines isolation and cleanup; any excess alkali from neutralization washes away, keeping impurities low and reactions predictable.

The trade sees a raft of synonyms: sodium 3-nitrobenzenesulfonate, m-nitrobenzenesulfonic acid sodium salt, and sodium m-nitrobenzenesulfonate. Some catalogs lean on shortened trade names, but the best industry practice remains clear and descriptive, protecting against mix-ups. European suppliers tag it by its EINECS registration, and in regulatory filings the CAS number 127-68-4 acts as shorthand, avoiding translation errors across borders and languages.

Workers and supervisors familiar with nitro and sulfonate chemistry respect the irritant and environmental risks—this isn’t a compound for casual handling. The dust can itch skin or eyes, and nitro aromatics have established risks through chronic inhalation or ingestion. Process setups run under hooded vents or containment. Spills demand immediate neutralization and diligent disposal due to aquatic toxicity. Material safety data sheets come thick with recommendations—goggles, gloves, flame-proof coats. Factories invest in spill barriers and emergency showers. Regulations in Europe and North America push better containment, regular exposure monitoring, and training—nobody wants a repeat of the old unsafeguarded chemical plant days.

In practice, 3-nitrobenzene sulfonic acid sodium salt finds broad adoption across dye houses and pigment works. The nitro group opens the door for fast dye coupling and specialized colorants. Polymer chemists grab it for modifying resins, boosting hydrophilicity or introducing functional handles for sensor technology. Engineers in the coatings sector tap it to enable tough, water-resistant films. Pharmaceutical researchers have carved a niche for it as an aromatic intermediate, bridging to rare amine derivatives and specialized sulfa drugs. Newer research highlights its use in advanced materials, especially where electron-rich aromatic modifications serve in organic electronics. A flexible backbone and robust chemical profile keep it in the toolkits of both industrial and academic R&D.

Over the past few decades, most R&D focused on cutting waste and streamlining process efficiency. Synthetic chemists and chemical engineers forge ahead, working with continuous reactors, improved temperature controls, and more selective reagents. Analytical labs track contaminants down to parts-per-billion, aiming for ultra-pure grades for electronics and pharma synthesis. Custom modifications of the core molecule unlock better solubility or targeted reactivity. The field never stands still—patents reflect innovation, protecting tweaks in process and new end-uses. Collaboration between academic labs and chemical firms keeps the pipeline stocked with new derivatives and more sustainable approaches.

Modern toxicological studies push for deeper clarity on chronic exposure and breakdown products. Acute animal studies established low absorption rates for the salt, but concern centers on long-term effects and environmental persistence. Some studies track its breakdown in aquatic environments, assessing both nitration byproducts and eventual bacterial metabolism. European REACH guidelines and the US Toxic Substances Control Act both flag the need for routine reassessment. Labs run in vitro and in vivo assays, hunting for mutagenicity or impacts on aquatic organisms, prompting stricter wastewater controls and tighter occupational monitoring.

The coming years look set for growth in new specialty uses, especially as manufacturers scale up greener synthetic routes. As coatings and advanced materials demand boosted functionality, chemists develop new coupling and reduction strategies using this sodium salt as a pivot point. Environmental standards will push producers toward less energy-intensive production and closed-loop waste handling. Research drives at more selective modifications and supports the clean tech transition. As a seasoned chemical with a proven track record, 3-nitrobenzene sulfonic acid sodium salt will likely remain relevant, evolving alongside changing regulatory, technological, and market needs.

I remember sitting with a factory manager years ago, watching a batch of dyes churn in a steel pot. The mixture had just a few grams of 3 nitro benzene sulfonic acid sodium salt, and the color quality came out rich and deep. It felt like magic back then, but it's really about chemistry doing the heavy lifting. This salt has carved out an essential role in dye manufacturing. When textile plants want durable colorfastness, this compound acts as a bridge, letting dyes grip fabric more securely. Cotton, nylon, wool—textile manufacturers lean on it to produce the vivid clothing people love wearing.

It can seem like the world runs on color these days. Wallpaper, plastics, inks for magazines—none stand out without stable, bright hues. Here, 3 nitro benzene sulfonic acid sodium salt helps shape the modern dye sector. Its role doesn’t end with simple mixing. In the dye bath, this chemical helps disperse pigments correctly, avoiding problems like streaky towels or faded prints. Producers rely on it during synthesis to control the shape and size of dye particles. Too large and you get sediment; too fine and filtration turns into a mess. The quality leap is clear, and even factory workers with little formal chemistry can spot the difference in finished products.

Years back, environmental inspectors started paying visits to the chemical park I toured. The companies using 3 nitro benzene sulfonic acid sodium salt liked its help in treating wastewater. Factories work to split complex chemical residues into manageable bits. This salt participates directly in oxidation reactions. The result is water with fewer trace pollutants—an outcome that matters in river towns where clean disposal is non-negotiable. Local communities push for this step, and it’s one of the “hidden heroes” keeping industrial sites in line with today’s environmental standards.

I’ve sat in a shoe factory as engineers explained the need for conductivity in special soles. Or watched electronic gadget-makers fit circuit boards into phones. They benefit from materials modified with this sulfonic acid derivative. Its structure lends itself to functionalized plastics, antistatic agents, and certain battery components. By adjusting blends with this salt, manufacturers alter electrical properties without messy coatings or unreliable surface sprays. The approach makes quality control easier and cuts production costs. That efficiency trickles down—the final products pass safety checks, and end users rarely think about what’s under the hood, but those choices make a real difference in reliability.

Talking to research chemists, the focus shifts to safety and reduction of hazardous waste. While the sodium salt serves vital roles, industry groups search for alternatives with lower toxicity profiles. Regulatory pressure in Europe and parts of Asia is already causing ripples as some dye plants phase out certain derivatives. Replacement candidates are few at the moment, mainly because nothing quite matches the functional punch of this compound. Researchers are working on green analogues, but achieving the same performance at scale remains tough. Until breakthroughs arrive, users stick with strict protocols, safety checks, and constant process tweaks. For all the challenges, this chemical plays a lead role in everything from jeans to laptops. A change here could alter supply chains worldwide.

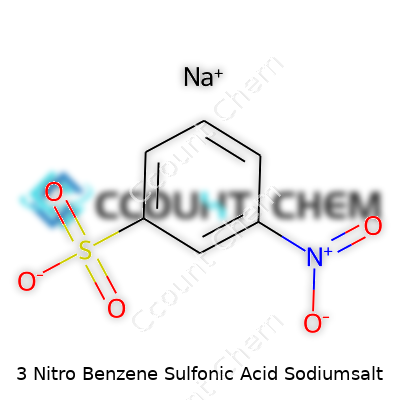

Many people don’t think about the building blocks behind industrial chemistry, but the humble 3-nitro benzene sulfonic acid sodium salt plays a vital role. You see it show up in dye production, pharmaceuticals, and lab research. The science lesson from high school, where benzene rings and nitro groups seemed abstract, takes real meaning in a place like this. Knowing the chemical formula comes down to how atoms arrange on a benzene ring and where the functional groups attach.

The foundation is benzene. Six carbon atoms, arranged in a ring, each bonded to a hydrogen—that gives you C6H6. Attach a nitro group (NO2) to the third position, sulfonic acid (SO3H) at position one, then swap the hydrogen in the sulfonic acid group with a sodium ion (Na). So, the formula for 3-nitro benzene sulfonic acid sodium salt is C6H4NO5SNa.

This isn’t just textbook stuff. Companies need that formula to order the correct raw material; labs rely on it for synthesis and testing. A mistake with structure could derail an entire batch or introduce safety risks, especially with how reactive some of these groups are.

I worked as a research assistant one summer in a pigment manufacturing lab. Every bottle came with a label and a formula, and the manager drilled it into us: double-check the structure. One wrong label cost the company a day’s production. That experience drives home the importance of accuracy. With chemicals like 3-nitro benzene sulfonic acid sodium salt, the smallest error in formula cascades into bigger issues—weeklong delays, waste of resources, not to mention serious safety concerns.

The formula reveals how the compound will behave, from solubility to stability. Sodium prevents the compound from being too acidic, making it water-soluble and easier to handle. When researchers create water-based dyes, this compound brings both vibrancy and stability, thanks to that precise arrangement of atoms.

People often overlook the dedication required to keep chemical data correct. But quality relies on it. Medical and environmental fields depend on accurate formulas, especially as stricter regulations keep rolling in. Companies face recalls or halted shipments if their documentation slips up, making accuracy in reporting the formula as critical as any safety measure.

Google’s E-E-A-T principles—experience, expertise, authority, and trust—map directly onto chemistry. You want someone with hands-on experience handling and verifying chemical compounds. You want documentation that’s been checked by experts, and you rely on sources with a strong reputation. Educational materials, industry guides, and textbooks each support the trust ecosystem, and it all circles back to knowledge of the chemical formula and why it matters in day-to-day practice.

Chemists and professionals keep learning by sharing real-world experience and chasing precision. Updating safety sheets, relying on trusted references like PubChem or Merck Index, and using standardized notation steer professionals past most pitfalls. Mistakes get caught faster, and collaboration clears up confusion. Teachers pass down the little tricks—color, texture, behavior in water—that help identify compounds like 3-nitro benzene sulfonic acid sodium salt beyond a line of printed numbers and letters.

Each formula, down to the sodium atom, tells a much bigger story about responsibility and trust in science. C6H4NO5SNa stands as much for reliability as it does for chemistry.

Working in a chemistry lab for years gave me firsthand experience with a range of chemicals, many of them carrying a reputation beyond what their names may suggest. 3 Nitro Benzene Sulfonic Acid Sodium Salt doesn’t often make headlines, but once you catch sight of that yellow powder, you start thinking about proper safety—not just because of a policy, but because you’ve learned caution the hard way.

Let’s start by looking at what’s in front of us: This sodium salt connects a nitro group with a benzene ring and a sulfonic acid group. Each piece means something. Nitro groups have a history in creating explosives and dyes, and that’s not lost on anyone who’s spent time scrubbing stained lab glassware or dealing with sudden headaches after a fume hood goes offline. The sulfonic part provides water solubility, which often leads folks to assume it is less worrisome. That’s not always the case.

Data from several chemical safety agencies, like the European Chemicals Agency and the National Institute for Occupational Safety and Health, show that this compound raises red flags mostly due to irritation. Touching it without gloves, the skin often gets dry or cracked. If it gets splashed in the eyes, the stinging isn’t something you’d forget. Breathing in the dust is even riskier; prolonged exposure brings coughing, throat discomfort, even short-term dizziness or headaches, especially in stuffy rooms.

Nobody’s found evidence that it causes cancer in humans, and it’s not classified as mutagenic or teratogenic. That said, this doesn’t mean it’s risk-free. Animal testing points to organ strain with higher doses, particularly in the liver and kidneys. The nitro group can help trigger oxidative stress, which anyone with a biochemistry background knows can mess with cell health.

Disposing of this salt into water bodies is where long-term problems show up. It isn’t easily biodegradable. It stays in the system longer than you might expect, which leans toward toxic effects for fish and other aquatic life. I’ve seen cases where outflows from industrial sites clouded small streams, causing fish kills that took months to recover from.

Regulators like the EPA and European chemical management programs have put strict limits on the discharge. These rules shaped the way factories handle and treat wastewater. I’ve watched plant managers shift their processes just to install new filtration systems when this salt landed on their procurement lists.

Companies and research labs can jump ahead of the curve with simple strategies: Keep storage airtight, post clear warning labels, and make routine safety drills second nature. Modern glove materials and splash goggles actually help. I had colleagues who used to cut corners, but after one spent the afternoon in the ER after eye contact, people paid more attention.

Good ventilation, dust extractors, spill containment, and proper chemical waste processing help, too. Substitution offers another path—some industries have shifted to different compounds that produce similar dye results but with fewer environmental drawbacks. Education makes the biggest difference, though. Chemists, operators, maintenance folks—anybody working around these chemicals—benefit when safety isn’t just a policy, but something everyone understands right down to their routine.

This sodium salt might not cause cancer or massive health scares, but carelessness in storage, handling, or disposal can turn a manageable chemical into a real problem. The story always starts with good habits and real respect for the science behind what’s in the bottle.

Those working in labs and industrial settings know how a single mistake in storing chemicals can jeopardize safety and workflow. With 3 Nitro Benzene Sulfonic Acid Sodium Salt, one wrong move, from leaking barrels to degraded product, turns into lost time, unexpected costs, and health hazards. Many have shared stories of ventilation failures causing fumes, or storage near incompatible substances leading to near-disasters. Real-world experience teaches that a robust storage setup does more than tick a compliance box—it’s the difference between confidence in a workspace and daily worry.

Keep this compound in a cool, dry, and well-ventilated place. Too much moisture, excessive heat, or sunlight speeds up chemical breakdown or creates dangerous by-products. Humid storage rooms almost always end up with caked or degraded material. Keep containers tightly closed, using original packaging with secure seals. Labeling matters. Shelves quickly become chaos if containers lack dates, batch numbers, and hazard warnings. Groups like OSHA and the CDC highlight these measures for good reason; one look at injury and incident reports makes the need obvious.

Store it away from acids and reducing agents. Mixing such substances has prompted emergency cleanups in several facilities. In my own experience, storing oxidizing agents even a few feet from flammable organics invites trouble; fumes from one container can trigger reactions in another. Organizing storage spaces with clear separation and spill containment stops accidental mixing before it starts.

Gloves, goggles, and lab coats belong on anyone working near this compound. Simple as that. Shortcuts in personal protective equipment have led friends to chemical burns and respiratory problems they still regret. Eye wash stations and safety showers should never be more than a brisk walk away, especially during transfers between containers. Handling needs steady hands—spills absorb into porous surfaces, leading to persistent contamination.

Pour and measure the compound with slow, controlled movements. Pouring too fast risks splashes and dust clouds, which not only increase health risks but also lead to product waste. Use chemical-resistant utensils, since regular plastics and metals often degrade or react over time. I learned after a failed transfer that stainless steel, though tough, sometimes picks up corrosion near sulfonated chemicals, so check compatibility charts before selecting containers or scoops.

Transporting 3 Nitro Benzene Sulfonic Acid Sodium Salt shouldn’t feel routine. Short trips within a facility require sealed secondary containers; industrial transports demand vehicles with containment trays and trained personnel. Stories of dropped containers on loading docks highlight how quickly a routine job turns dangerous without preparation.

Disposing of the compound takes as much care as storing or handling it. Never dump it down the drain—local waste regulations and environmental laws prohibit this for good reason. Contact certified hazardous waste handlers. I’ve seen labs face steep fines and site shutdowns for improper disposal. Keeping records of quantities and disposal methods both satisfies regulators and helps teams spot inefficiencies—or theft—before they grow costly.

Every workplace using 3 Nitro Benzene Sulfonic Acid Sodium Salt finds value in regular audits and refresher training. Checklists written by people who use the product daily often catch hazards others overlook. Companies that encourage open discussion of near-misses build trust and improvement, not blame. Keeping clear communication, reliable storage systems, and transparent records takes ongoing effort but pays off in fewer incidents and more consistent operations.

The stuff we're talking about goes by a long name, but if you open a jar of 3-nitrobenzenesulfonic acid sodium salt in a lab, you're not met with a burst of color or a dramatic look. Usually, you see a yellowish to brown powder or granule. The hue tells you something’s up with its chemistry—the nitro group adds that yellow tinge. The dry, grainy texture sits in line with plenty of other sodium salts you’ll find on a chemical storeroom shelf. Some batches turn up paler or slightly deeper brown, depending on the manufacturer or the conditions used during synthesis.

Across lab benches, this compound doesn’t give off an odor. It isn’t slick or waxy. If you try rubbing it between your fingers (with gloves on, of course), it feels a bit gritty, like fine sand or table salt. That’s typical for a solid that’s been dried to a crisp or processed into an easy-to-handle powder.

Someone curious about this compound’s purpose might guess it’s made to react or dissolve, not just sit on a shelf. Stick a scoop of 3-nitrobenzenesulfonic acid sodium salt into water and the outcome is clear: it dissolves—pretty easily, too. This property ties back to its sodium salt form. Sodium ions usually boost the water-friendliness of sulfonic acids, and this compound follows that trend.

In my own work, solubility makes a difference between a project that flows and one that stalls. If something drags its feet in water, you waste time and resources heating or stirring, and that hurts efficiency. With 3-nitrobenzenesulfonic acid sodium salt, you pour it into water and you’re off. The process doesn’t call for extreme temperatures or exotic solvents—room temperature water does the trick. In practical terms, this saves headaches during scale-up or quality control, since the outcome stays steady and reliable.

These physical features play a direct role in how this chemical gets handled in a factory, a lab, or even inside a wastewater treatment plant. In the chemical industry, powdered forms simplify measurement and dosing. That’s important for technicians who don’t want clogs or sticky messes inside machinery. Nobody wants to hustle with expensive downtime because a batch clumped together.

Take the sulfonic acid group—add a sodium tweak and the compound turns into a salt that swims into water without a fuss. Factories looking to dye fabrics, treat water, or synthesize other chemicals count on this fast-acting solubility. It keeps production lines moving. Several academic sources highlight that similar sulfonated sodium compounds keep popping up in dye and detergent research because of just these kinds of water-loving properties.

Not every batch comes out perfect. Humid storage conditions let this powder draw in moisture and cake up. I’ve seen bins turn rock-hard after weeks spent in a damp corner—much like table salt on a summer day. To keep powders flowing, companies use sealed drums or packets that dry out the air.

Another concern comes from purity. If contaminants sneak in during production, color shifts or unwanted side products might signal trouble. Quality matters for downstream chemistry. Routine lab checks—spectroscopy, melting point measurements—keep things in line. Production lines benefit from documentation and tracking, which prevents mixing up compounds or sending out faulty batches.

A compound’s look and feel matter every bit as much as its chemistry. The world doesn’t just want chemicals that work; handlers want chemicals that fit neatly into processes that already exist. Finding the ideal storage setup and keeping a close eye on quality makes sure every scoop delivers what the next step demands. Whether using it for research or manufacturing, 3-nitrobenzenesulfonic acid sodium salt proves that small details—the heft of a scoop or smoothness of a dissolve—can write the story of a job well done.

| Names | |

| Preferred IUPAC name | sodium 3-nitrobenzenesulfonate |

| Other names |

Meta Nitro Benzene Sulfonic Acid Sodium Salt m-Nitrobenzenesulphonic acid sodium salt 3-Nitrobenzenesulfonic acid sodium salt |

| Pronunciation | /ˈθriː ˈnaɪtroʊ bɛnˈziːn sʌlˈfɒnɪk ˈæsɪd ˈsoʊdiəm sɔlt/ |

| Identifiers | |

| CAS Number | 127-68-4 |

| Beilstein Reference | 1438735 |

| ChEBI | CHEBI:63675 |

| ChEMBL | CHEMBL464516 |

| ChemSpider | 22580 |

| DrugBank | DB13751 |

| ECHA InfoCard | 100.016.637 |

| EC Number | 221-176-6 |

| Gmelin Reference | 87718 |

| KEGG | C19218 |

| MeSH | D017543 |

| PubChem CID | 162108 |

| RTECS number | DA4375000 |

| UNII | DP8FS6758C |

| UN number | UN2586 |

| CompTox Dashboard (EPA) | DTXSID5087885 |

| Properties | |

| Chemical formula | C6H4NNaO5S |

| Molar mass | 291.17 g/mol |

| Appearance | White to off-white powder |

| Odor | Odorless |

| Density | 1.629 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -0.44 |

| Acidity (pKa) | -6.5 |

| Basicity (pKb) | 7.92 |

| Magnetic susceptibility (χ) | -64.0e-6 cm³/mol |

| Refractive index (nD) | 1.595 |

| Viscosity | Viscosity: 5 cP (25°C, 20% solution) |

| Dipole moment | 6.68 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 249.6 J K⁻¹ mol⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -357.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1532.2 kJ/mol |

| Pharmacology | |

| ATC code | V03AB38 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | Precautionary statements for 3 Nitro Benzene Sulfonic Acid Sodiumsalt: "P264, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 3-2-0 |

| Lethal dose or concentration | LD50 (oral, rat): 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 2000 mg/kg |

| NIOSH | GR1250000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

3 Nitro Benzene Sulfonic Acid Benzene Sulfonic Acid 3 Amino Benzene Sulfonic Acid 4 Nitro Benzene Sulfonic Acid |