Chemistry owes a lot to the small discoveries that turn up big results in the lab. Back in the 1970s and 1980s, folks started searching for an alternative to the classic grain refiners and brighteners in metal finishing. Electroplating needed safer, more reliable additives. 3-Mercapto-1-propanesulfonic acid sodium, better known in many circles as sodium MPS or MPSA-Na, answered that call. Researchers found that adding this compound dramatically improved copper plating baths, changing not just the speed but also the quality of plating. Factories across East Asia and Europe quickly picked up on the benefits. The demand for ever-thinner, more reliable circuit boards pushed this chemical into a global spotlight, especially after rapid tech expansion in the 1990s. Now, you’d be hard pressed to step into a plating plant and not bump into it in some form or another.

Sodium MPS carries a rather plain face, yet it works tirelessly behind the scenes. This product pops up in the production sites as a white or off-white crystalline powder. It goes by several names beyond its mouthful of an IUPAC: sodium 3-mercaptopropanesulfonate, sodium mercaptopropane sulfonate, MPSS, and a handful of trade names depending on country and manufacturer. The reason labs and factories keep it around is simple: it makes electroplating copper faster, smoother, and finer. No bells and whistles, only reliable action in the tank. Their shipping drums and plastic bags might draw little attention, but the compound inside gets the job done.

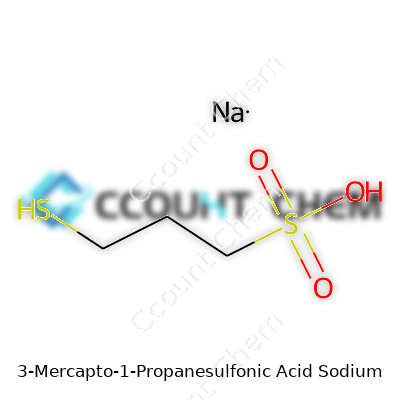

Sodium MPS is a stable, water-loving salt. The powder dissolves quickly in water, sparing no time for messy sludge. Its chemical formula—C3H7NaO3S2—shows two big functional groups: the thiol group (–SH) and the sulfonate group (–SO3Na). The thiol acts as the “hook” riding along surfaces, while the sulfonate opens the doors to water, letting the powder spread without clumping. The compound sits comfortably at room temperature, without odd odors, though the faint trace of sulfur on your nose might betray its presence. Measurements show a melting point above 200°C (decomposing), and you won’t see much change even if the humidity shifts. The high solubility brings another bonus for the tech folks—easy mixing, fast solutions, and even dispersion.

Specifications track purity like a hawk watching prey. Most industrial buyers look for sodium MPS with purity above 98%. Companies label containers with pointed precision—HS code, batch number, weight, and hazard data. Labels often mark UN numbers and GHS hazard pictograms. The transit and storage guides highlight dry, cool storage, away from acids that could steer the sample into trouble. Experience in the lab shows every percent of purity counts. Impurities, even small ones, mess up deposition results, wasting hours on rework or failures on electronics lines. So quality control teams rely on accurate titration and high-performance liquid chromatography for every lot leaving the plant.

The synthesis brings together raw chemical basics with a big dash of patience. Over the years, manufacturers settled mostly on one route. Start with 3-chloro-1-propanesulfonic acid sodium salt as the backbone, mix in sodium thiosulfate, and run the reaction in water under mild heat. The mixture steers through nucleophilic substitution—a classic maneuver, swapping the chlorine for mercaptan. Operators then bring in acidification and filtration, followed by re-neutralization. Plenty of rinsing takes any trace of leftover thiosulfate out, as it could otherwise tamper with the properties of the final batch. Each batch is then dried and tested, chasing away moisture for the sake of stability. This method, honed over decades, pushes out large volumes without high risk.

Sodium MPS gets attention in the lab for more than just what it brings to the plating tank. The thiol group leaps into action, acting as both a nucleophile and a mild reducing agent. It forms solid bonds with metals like copper and silver. Engineers use this feature to anchor additives and stabilizers in electrolytic baths. Chemists sometimes tweak the backbone, swapping in different counter-ions or shifting the chain length to play with performance. Under oxidative conditions, the thiol oxidizes, and the product turns to its disulfide, losing the brightening punch. Folks have tried chemical modifications, hoping to make additives with a longer shelf life or a gentler environmental profile, but the original sodium form still holds the most ground in production environments.

Globally, this product keeps several aliases on its passport. Laboratories use “MPS sodium” or “sodium MPS.” Academic literature sometimes writes out 3-mercapto-1-propanesulfonic acid, sodium salt. In the trade circuit, you’ll spot terms like mercaptopropanesulfonate sodium or sodium MPSA. Big chemical suppliers from Europe to China and North America stick to these core names, with only minor local branding differences. Every distributor tacks on their own batch numbers, but the CAS registry number—17636-10-1—makes identification possible no matter where samples go.

Like most water-soluble thiols, sodium MPS calls for good handling practice. Splash in the eyes or open wounds stings, and some sensitive folks develop mild skin reactions. Air quality stays comfortable, as it does not dust easily nor emit strong fumes. Workplaces keep Material Safety Data Sheets on file and post hazard signs where bags get opened. Training covers proper PPE: gloves, goggles, dust masks. The GHS guidelines recommend storing it away from acids and oxidizers. Most companies install spill kits and require documentation for disposal, as runoff could put a hit on aquatic life if left unchecked. Over decades, injury rates involving MPSA sodium remain low, though some operators share stories of irritation from spills that happen during high-speed downtime maintenance.

The lion’s share of demand comes from the electroplating industry. Anyone who has handled multilayer printed circuit boards or smartphone connectors has counted on sodium MPS in some step of the process. Its role in copper electroplating stands out—helping form fine grain structure, boosting deposit speed, and keeping surfaces bright without pitting. As automotive wiring and compact electronics have shrunk by the year, tighter control over copper thickness and adhesion has never mattered more. Research outfits trial it with nickel, gold, and silver baths, but copper stays at the heart of the business. Smaller batches have popped up in life sciences, where chemists use it to modify proteins or surfaces in lab diagnostics, though these areas barely dent the worldwide supply.

Innovation doesn’t rest, not even for a well-established chemical player. Every trade show, research group, and process engineer keeps searching for the next edge. Lab trials in Germany, Japan, and the US focus on boosting both bath lifespan and energy savings, especially as companies race to lower their environmental impact. A few academic studies play with the thiol group, adding tags for biosensors or developing unique catalysts. Most real-world gains come from adjusting the activity or ratio of sodium MPS to leveling agents in new plating formulations. Some R&D teams chase greener synthesis methods, swapping out older raw materials for renewable feedstocks or aiming to reuse spent baths more effectively. Collaborations between universities and industry giants keep pushing new ways to beat current plating benchmarks.

Sodium MPS rarely rings alarm bells for acute toxicity. Animal studies clock high LD50 values for oral exposure, meaning it would take large amounts to reach dangerous levels quickly. Regulatory reports show low chronic risk for standard workplace exposure. Wastewater studies highlight concern for aquatic life, as thiol groups can disrupt microbial processes or overfeed sulfur cycles. Plating factories, especially in strict regulatory zones like Europe and California, watch discharge levels closely. Inhalation risks aren’t high, but folks working day after day near powders could develop mild irritation if ventilation slips. Long-term assessments keep tracking for surprises, but the current record supports careful, vigilant use more than outright bans. Routine screens for breakdown products keep operators one step ahead of any unexpected hazards.

Markets never settle for the status quo. Firms keep pressing for faster, cheaper, and safer solutions, and sodium MPS evolves with that chase. Makers of advanced circuitry demand brighter, thinner, denser copper traces every year—a job sodium MPS still delivers on. Yet the spotlight grows on green chemistry. If regulators clamp down on runoff, producers will face a double push: keep sodium MPS effective while lowering emissions and boosting recycling. Research labs bring nanotechnology and molecular tagging into focus, hinting at new corners this old workhorse might expand to. The material’s simple chemistry, wide tolerance for impurities, and robust performance let it stay ahead for now, but only because industry knowledge, regulatory pressure, and day-to-day operator skill keep moving along with it.

My experience in a hardware manufacturing facility taught me that smooth, shiny metal parts do not come out of machines looking perfect. That finish needs chemistry working behind the scenes. 3-Mercapto-1-Propanesulfonic acid sodium gets attention in the electroplating world as a powerful additive for copper plating baths. It helps create finer, brighter, more durable layers of copper on circuit boards and connectors. I remember techs caring about reliability and malfunctions—dull, brittle metal layers spell trouble later. Using this compound in plating baths creates a tight grain structure, cutting down the risk of cracks and poor conductivity. Electronics thrive when the plating chemistry helps tiny devices withstand heat and pressure.

In a job at an electronics company, I watched engineers debate about long-term corrosion on circuit boards. 3-Mercapto-1-Propanesulfonic acid sodium isn’t a household name, but inside a PCB factory, it matters. High-tech devices need consistent, low-resistance copper traces. If the copper’s too rough or patchy, digital signals stumble; the device lags or even fails. This chemical smooths things out, reducing surface defects that come from old-fashioned additives. Labs and fabs use it to keep production lines humming, especially where top performance means less waste and fewer repairs.

The battery market keeps growing, with electric vehicles and energy storage taking the lead. Batteries use copper foil at their core. Any impurity or roughness in the copper spells disaster for battery life and safety. From what I’ve seen, careful chemical control means everything. 3-Mercapto-1-Propanesulfonic acid sodium steps in to regulate the copper deposit’s texture in electrolytic foil production. The result: copper foil with consistent thickness and fewer defects. Companies producing lithium-ion batteries chase stable, reliable performance—and this additive is a regular part of the recipe.

Outside the electronics world, 3-Mercapto-1-Propanesulfonic acid sodium sometimes appears in water treatment. Heavy industry needs ways to pull stubborn metal ions out of wastewater before releasing it. This compound assists with complexing undesired metals, making extraction easier. Sustainable factories use every tool in the box to follow environmental rules. Using this chemical—among others—helps meet regulations and keeps neighborhoods around plants safe from pollution.

Safety around industrial chemicals comes up often in conversations with plant managers. Usage brings risks: chemical handling, waste, and environmental questions. Factories should train workers thoroughly, monitor wastewater, and look for places to recycle or neutralize leftover chemicals. For the tech sector, alternative formulations sometimes promise similar results with greener sourcing or safer handling. Teams running plating or etching have to weigh cost, performance, and sustainability—there’s no shortcut. Better filtration and more complete recovery on production lines go a long way.

Digging into which chemicals get used and why helps shine a light on the nuts and bolts of modern manufacturing. 3-Mercapto-1-Propanesulfonic acid sodium stands out not for its name, but for what it delivers: reliability, quality, and a real boost to the foundational parts behind electronics, batteries, and beyond.

People in electroplating circles, water treatment, and specialty chemical manufacturing run into 3-Mercapto-1-Propanesulfonic Acid Sodium often. Its formula, C3H7NaO3S2, tells a simple story: a backbone of three carbon atoms, a sodium salt, and two sulfur atoms that make this molecule do what it does. The sulfonic acid group and mercapto group bring unique properties, making it valuable as a brightener in copper electroplating.

The formula’s real-world value lies in its clarity for engineers, lab techs, and researchers. You don’t have to look far to see why so many technical sheets and MSDS entries use C3H7NaO3S2 as the universal chemical shorthand.

Every chemist has weighed samples for a reaction and realized how much the right number matters. The molecular weight of 3-Mercapto-1-Propanesulfonic Acid Sodium is 178.21 g/mol. That figure comes from a sum of the atomic weights for each element in the formula: three carbons, seven hydrogens, one sodium atom, three oxygens, and two sulfurs.

For anyone mixing plating solutions, preparing calibration standards, or just labeling containers, this number supports accurate dosing. Over the years, I’ve seen techs punch in the wrong value and spoil an entire bath—too much or too little, and the surface finish changes. Reliable production means getting the math right every time. There’s no shortcut for that discipline.

Some people ask why a simple number or formula gets such attention. Businesses working with chemicals stake big investments on product purity, compliance, and safety. 3-Mercapto-1-Propanesulfonic Acid Sodium, popular in tech industries, comes with regulations, batch checking, and traceability demands. Nobody enjoys a phone call from a customer saying their plating process failed or a regulator asking about your inventory.

The clear identification that comes from standardized chemical formulas and weights protects quality and shows respect for users down the supply chain. Training staff on fundamental facts like these cuts mistakes. It may sound simple, but these details cut rework, boost yield, and keep people safe.

Laboratories and production floors benefit from proper chemical labeling and digital recordkeeping. I recommend confirming entries from at least two sources and keeping standard operating procedures up to date. Peer review—even a buddy double-checking your math—makes a difference. Adopting these habits keeps the process smooth and reduces the risk of compliance headaches.

Also, encourage an open learning environment in the workplace. Juniors and newcomers might hesitate to ask about chemical formulas or weights, but sharing knowledge reinforces a proper safety culture. The more people know how to interpret C3H7NaO3S2 or recognize that 178.21 g/mol isn’t just a random number, the safer and more productive everyone becomes.

In the world of electroplating and industrial chemistry, people run into plenty of chemicals that need respect. 3-Mercapto-1-Propanesulfonic acid sodium salt (MPSNa) comes up a lot, especially in plating baths for metals like copper. The question keeps popping up: do you need to worry about safety with this particular chemical? Based on my time handling sulfur compounds and reading the manufacturers' literature, this isn't something you want to treat casually.

3-Mercapto-1-Propanesulfonic acid sodium brings together a mercapto group (think sulfur’s strong, sometimes stinky smell) and sulfonic acid, tied up as a sodium salt. It doesn’t jump out as explosively dangerous or highly toxic like some of the classic chemical nightmares in the lab, but that doesn’t mean it’s harmless.

The main concerns tie back to its high reactivity and the irritation risk. I remember a colleague forgetting to wear gloves—the substance left his skin red and itchy. Its pungent, garlic-like odor hits you right away, hinting at its potential to irritate eyes, skin, and especially lungs if you take a whiff or get a splash where it shouldn’t go. The material safety data sheets (MSDS) point to eye damage risk, possible respiratory sensitization, and some level of toxicity if ingested.

No cases came up in my circles of anything more than short-term symptoms, but research flags similar organo-sulfur compounds as problematic in higher concentrations. I can’t think of a case where someone got seriously harmed, but nobody had a reason to take such chances, either.

Factories using 3-Mercapto-1-Propanesulfonic acid sodium set up strict controls, and savvy lab techs always reach for gloves, goggles, and lab coats. The rules in most workplaces call for ventilated hoods and easy access to eyewash stations. Given the powder can turn into dust, respiratory masks come in handy, especially in bigger operations. The spill can strip your nose and eyes quickly, so neutralizing spills right away and washing up matters.

Disposal doesn’t allow for shortcuts either. You can’t just pour leftover solution down the drain. Most companies send waste away with certified hazardous material handlers, following environmental regulations. The sodium salt dissolves easily and travels in water, which raises the risk of getting it into the wrong places if safety steps are skipped.

Anyone working around this chemical benefits from in-depth training. I found that regular drills, clear labels, and buddy systems in the lab make the biggest difference. New staff often overlook how easily sulfur-based compounds can irritate, so hands-on instruction sticks better than any handout does. Investing in better fume hoods pays off in breathability and peace of mind.

Better packaging, such as resealable containers and clear hazard warnings, keeps things straightforward. Making sure everyone knows what to do if exposure does happen—quick rinsing for eyes and skin, getting to fresh air, calling for help if someone shows a strong reaction—keeps minor accidents from growing.

At the end of the day, the hazards tied to 3-Mercapto-1-Propanesulfonic acid sodium don’t come from lurking, silent threats. The real risks show up if people get lax or take shortcuts. Respect for basic protocols, good personal protective equipment, and solid training keep anybody mixing or plating metals far from unnecessary harm. In this field, shared know-how and a willingness to ask questions trump any complicated safety chart.

3-Mercapto-1-Propanesulfonic Acid Sodium, used in electroplating and a few niche manufacturing processes, isn’t the sort of thing people stack next to sacks of cat food. Anyone who’s spent time around chemical storage knows some materials just don’t forgive lazy handling. This one falls firmly into that camp. The shelf life depends less on luck and more on sticking to a handful of solid basics.

Humidity loves to creep in and ruin things, especially with sodium salts like this. In my experience walking the backrooms of small plating shops, corners get damp during heavy rains or steamy days in summer. Any uptake of moisture can set off a slow breakdown, changing how the chemical performs. Sealing the material in tightly closed containers, away from walls that get cold or wet, gives it a fighting chance. Every year, companies lose money on wasted inventory because nobody bothered to double-check a loose cap or a cracked bag. Fixing this early means money stays in your pocket and quality stays high.

Few things wreck specialty chemicals faster than storing them near uninsulated roofs or next to heat-generating equipment. Sodium-based compounds like this one keep their integrity at room temperature—somewhere between 15°C and 30°C feels right. Below freezing, things can clump or stratify. Upwards of 30°C, you’ll speed up the risk of slow reactions degrading the material. Years ago, I watched a batch stored near a furnace slowly degrade into uselessness; nobody caught it until plating results tanked. Keeping chemicals away from sunlight, ovens, or spotty heaters is just common sense, and it’s far less hassle than cleaning up the mess later.

Dirt, dust, spilled solutions—these find ways to hitch a ride whenever chemicals aren’t kept in order. Contaminants throw off everything from physical appearance to chemical reactivity. If the container sits open during transfer, don’t assume the surrounding air is clean. Use scoops that aren’t swapped between different powders or moved from shelf to shelf unwashed. Regularly wipe down benches and replace any cracked lids right away. Employees who skip these steps out of impatience often pay for it in wasted batches or botched process runs.

Label everything. I’ve seen shops lose track of what’s in which container after one too many unmarked buckets—this is how accidents happen. Whether you’re a small operation or a big plant, attach clear labels with the chemical name, date received, and lot number. Rotate stock religiously, using older material first. Any suspicion of a mix-up deserves a fresh batch rather than risking production.

Store this chemical away from acids and oxidizers. Even small cross-contamination risks are real in smaller spaces. If product goes off-spec or degrades due to poor storage, treat disposal as you would with any hazardous material: according to guidelines and with zero shortcuts. I’ve learned the hard way that shortcuts here may cause fines, damage reputations, or worse.

Years spent in industrial settings taught me that simple, disciplined storage saves time, money, and headaches. Manufacturers should build storage routines around dryness, steady temperature, cleanliness, and tracking. Over the long haul, this approach protects both safety and product performance, long before a batch ever reaches the production line.

Stepping into any plating or electronics facility, the phrase "close enough" just doesn’t cut it when discussing raw materials like 3-Mercapto-1-Propanesulfonic Acid Sodium. Just a small shift in purity levels can take a process from smooth sailing to a troubleshooting nightmare. This compound isn’t just a line item on a spec sheet—it’s a core part of the chemistry behind high-quality metal coatings, mostly used in copper electroplating baths for printed circuit boards and semiconductors.

Most industrial suppliers offer 3-Mercapto-1-Propanesulfonic Acid Sodium with active ingredient content ranging between 98.0% and 99.0%. A typical certificate of analysis lists minimum purity at 98%. Some companies push for 99%, especially in the semiconductor space, where the room for error shrinks to practically nothing due to trace contamination impacts. For chemistry labs, hitting even 98% often proves acceptable, but process engineers in tech facilities usually chase after material that's even cleaner. Lower grades—hovering around 95%—can end up driving up waste, process downtime, and inconsistent yields.

The biggest headaches usually come from inorganic salts, sulfates, and heavy metal traces. Just a fraction of copper or iron left in the material can skew an entire electroplating bath. Sulfate levels matter too, since too much can trigger unexpected crystallization or shift the pH outside a reliable window. In my own experience troubleshooting plating defects, it’s often these trace metals or sulfate imbalances that set off a wild goose chase for root causes. I've watched seasoned engineers send multiple complaints upstream to suppliers, only to realize the solution started with tighter testing and batch documentation.

Reliable suppliers deliver batch-by-batch certificates—far more than a checkbox exercise. Beyond minimum active percentage, customers ask for loss on drying data, heavy metal screenings (for things like lead, iron, copper), and a residue after ignition figure. Proper documentation gives customers ground to stand on during process investigations. Quality-focused buyers sometimes run their own independent purity checks, using titration or chromatography, to keep suppliers honest. One former colleague set up in-house GC-MS scans just to double-check sodium and sulfate content, catching two near-misses in a single year before they could upset a new product launch.

Every lab accident or batch recall tied to low-purity chemical feeds starts long before the chemist even opens a drum. Raw material audits, third-party verifications, and up-to-date test methods stop most trouble before it takes hold. Bringing those steps in early saves more headaches than any after-the-fact workaround. For production floors, a little more spend on top-grade 3-Mercapto-1-Propanesulfonic Acid Sodium often nets out against massive savings on waste remediation, rework, or lost business from shoddy finished goods.

True progress shows up when companies push suppliers for not just the standard 98% purity but for voluntary disclosure of all expected side products and trace elements. Open conversations about testing methods and batch consistency build the kind of trust that's tough to fake. When everyone along the chain—lab techs, production managers, procurement—gets on the same page about quality, those tiny numbers on the label start to mean something real.

| Names | |

| Preferred IUPAC name | Sodium 3-sulfanylpropan-1-sulfonate |

| Other names |

Sodium 3-mercapto-1-propanesulfonate Sodium 3-mercaptopropane-1-sulfonate MSA-Na 3-Mercapto-propane-1-sulfonic acid sodium salt Sodium salt of 3-mercapto-1-propanesulfonic acid |

| Pronunciation | /ˈθriː mɜːrˈkæp.toʊ waɪ ˈproʊˈpeɪnˌsʌlˈfɒnɪk ˈæs.ɪd ˈsoʊdiəm/ |

| Identifiers | |

| CAS Number | 17636-10-1 |

| 3D model (JSmol) | `/pdb/model_plugin.php?id=3MP` |

| Beilstein Reference | 3908439 |

| ChEBI | CHEBI:91221 |

| ChEMBL | CHEMBL1598760 |

| ChemSpider | 121349 |

| DrugBank | DB04345 |

| ECHA InfoCard | 03ca93d9-72a0-4cf1-8099-359c0c738173 |

| EC Number | 2930-37-8 |

| Gmelin Reference | 84856 |

| KEGG | C19809 |

| MeSH | D017937 |

| PubChem CID | 23733282 |

| RTECS number | TH7875000 |

| UNII | 6Q70AF9Q82 |

| UN number | UN2922 |

| CompTox Dashboard (EPA) | DTXSID1020727 |

| Properties | |

| Chemical formula | C3H7NaO3S2 |

| Molar mass | 174.18 g/mol |

| Appearance | White to off-white crystalline powder |

| Odor | Odorless |

| Density | 1.46 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -3.5 |

| Vapor pressure | 1.7 Pa (25 °C) |

| Acidity (pKa) | -2.0 |

| Basicity (pKb) | 9.11 |

| Refractive index (nD) | 1.4700 |

| Viscosity | 1100 cP (25 °C) |

| Dipole moment | 5.1132 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 212.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -895.0 kJ/mol |

| Pharmacology | |

| ATC code | A16AA11 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | Precautionary statements: P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Flash point | > 248.5 °C |

| Autoignition temperature | > 230 °C |

| Lethal dose or concentration | LD50 Oral Rat 3600 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 > 2000 mg/kg |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.2-0.6 |

| Related compounds | |

| Related compounds |

1-Propanesulfonic acid 3-Mercaptopropionic acid Sodium 1-propanesulfonate 2-Mercaptoethanesulfonic acid Sodium 2-mercaptoethanesulfonate |