Back in the heyday of buffer innovation, researchers started experimenting with sulfonic acids and their derivatives, recognizing their value in precise pH control for biochemical studies. 3-Cyclohexylaminopropane-1-sulphonic acid, often abbreviated as CAPS, emerged as part of this wave around the 1960s and 70s when Good’s buffers, so-called after Norman Good, started to replace less stable and less biocompatible options. Its structure allowed scientists to probe protein chemistry at high pH ranges without worrying about unwanted interactions, a real breakthrough for those chasing purity in their protein prep. From early publications, its reputation grew among biochemists, and it earned its spot in practical lab handbooks everywhere. For decades, CAPS has remained a staple for investigating enzymes, running electrophoresis, and fine-tuning the conditions under which proteins reveal their secrets.

CAPS is no magic compound, but it sure gets a lot of attention for its role in biochemistry. Sitting in the class of sulfonic acid buffers alongside HEPES and MES, CAPS stands out mostly for its pKa around 10.4 at room temperature, making it a solid choice for studies near the alkaline edge. Researchers turn to CAPS when they need a buffer for enzymes or processes that don’t like acidic or even neutral environments. In terms of availability, anyone venturing out to buy biochemicals will spot it under various pack sizes, often packaged for lab and pilot plant use. While it can be more expensive than commodity buffers, its performance justifies that premium in high-stakes research.

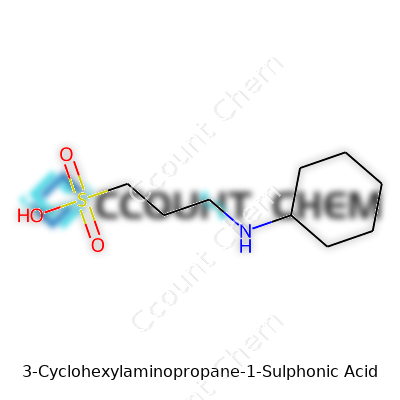

The molecule itself brings together the cyclohexylamine structure and a propanesulphonic acid chain. That cyclohexyl ring isn’t just aesthetics—the bulk provides resistance against enzymatic breakdown. With a molecular weight just under 230 g/mol, CAPS dissolves well in water, revealing its role as a buffer. It turns up as a white to off-white crystalline powder. At room temperature, you won’t have much luck dissolving it in non-polar solvents. Water solubility hovers around 100 grams per liter at 20°C, with solutions remaining clear when mixed right. In use, it keeps its cool, even at higher temperatures, just as many PCR, DNA sequencing, and blotting procedures demand. The buffer capacity pairs with this thermal stability, giving CAPS a niche that few other buffers manage to fill.

Whenever labs order CAPS, they look for purity no less than 99%. Common labeling practices list the CAS number (1135-40-6), identity tests, and minimum assay by HPLC or titration. Appearance, solubility, moisture content (by Karl Fischer or thermogravimetric analysis), and residue after ignition round out the certificate of analysis. Many suppliers add trace metal and UV-absorbance details, crucial for applications in spectroscopy and high-sensitivity research. Product data sheets outline precautions for safe handling, usually referencing Globally Harmonized System (GHS) standards.

Producing CAPS takes a few deliberate steps. Manufacturers start with cyclohexylamine, subject it to reaction with 1,3-propane sultone or an activated sulfonation agent in a controlled basic medium. This stepwise approach marks significant progress from earlier routes that struggled with low yields. Once sulfonation closes, the product migrates into water where purification starts, sometimes through crystallization, other times by ion-exchange chromatography. Drying brings the product to its final form. These processes evolved to deliver better purity, avoid unreacted precursors, and reduce waste, all of which matter for labs and the environment alike.

Chemists often leave CAPS alone, since its value lies in its stability and lack of interference. Even so, some creativity has gone toward modifying its side chains, aiming to tweak its buffering range or solubility. The cyclohexyl ring interacts predictably with hydrophobic environments, but swapping out that group hasn’t yielded mainstream alternatives quite so robust. Under strongly basic or oxidizing conditions, decomposition can occur, breaking apart the sulfonic or amine bonds, which is why labs take care storing and disposing of solutions over time. Most modification efforts focus on metallation (binding to metal ions) for catalysis tests, but these applications are niche compared to its workhorse buffer duties.

Throughout catalogs, CAPS appears under several aliases: 3-Cyclohexylaminopropane-1-sulfonic acid, N-Cyclohexyl-3-aminopropanesulfonic acid, or just by its acronym. The standardized name smooths purchase orders and regulatory submissions, keeping confusion at bay. In procurement channels, suppliers stick to these names, cross-referencing the CAS registry number to keep things consistent worldwide.

Labs work with CAPS using standard PPE—gloves, goggles, lab coats. Toxicity sits on the low end of the scale, but powder can irritate the respiratory tract. Safety data sheets highlight this, recommending dust extraction and using it in well-ventilated areas. Professionals treat spills by diluting with water and mopping up solid residues, segregating for chemical disposal. No special fire hazard stands out, but decomposition at high temperatures brings the risk of sulfur oxides. Adhering to best practices, including those from OSHA and REACH, keeps risks manageable. Vendors comply with labeling and shipping standards, so researchers receive it ready for safe storage in cool, dry places, away from direct sunlight or reactive chemicals like strong acids.

The only way to appreciate CAPS is by seeing its reach: biochemical research, pharmaceutical testing, protein purification, western blotting, and enzyme activity studies. Its high pH buffering puts it squarely in workflows where other buffers risk denaturation or loss of activity, such as advanced electrophoresis. Research on plant and animal enzymes often cites CAPS as the buffer of choice, especially for kinetic analysis. Outside academia, quality control labs in diagnostics and biotechnology routinely keep it on the bench. Since it doesn’t absorb interfering wavelengths in visible and UV ranges, instrumental studies rely on it for reproducibility.

R&D hasn’t rested in pushing CAPS further, not just for new applications but for sustainable manufacture. Green chemistry approaches now guide many suppliers to shift toward solvent-free or recyclable processes. Startups and academic labs test derivatives in efforts to expand the pH window or target different biological samples. Analytical tools keep growing sharper, yielding more details on trace impurities, shelf life, and impact on sensitive detection methods like mass spectrometry. The trend goes toward customizing buffer systems, but CAPS holds a stable place, often serving as the foundation for cocktails designed to tackle more complex samples.

Scientists examined CAPS in cell-based assays and animal studies, finding low acute toxicity. No significant mutagenic or carcinogenic effects turned up, though chronic exposure data stay limited. Acute oral and dermal LD50 values stay high, suggesting minimal harm outside mishandling or allergic responses. Some studies hint at possible non-specific effects at concentrations far higher than those used in the lab. Researchers advocate for using the minimum effective concentration, supported by environmental regulations that monitor effluent from large-scale production. Regular reviews update the risk profile as new data come in.

CAPS won’t be fading from research scenes any time soon, given the steady demand for robust buffers as protein chemistry keeps evolving. Novel protein drugs, biosimilars, and analytical assays hinge on precise conditions, and CAPS continues to support that quest. Digitalization pushes data-driven approaches in formulation, and CAPS factors into the feedback loops refining buffer recipes. With environmental pressures mounting, industry looks toward biodegradable coupling chemicals and less energy-intensive synthesis, areas where new minds can move the field forward. As life science and analytics intersect, there’s room for testing hybrids or entirely new buffer scaffolds taking cues from the core sulfonic and amine chemistry of CAPS.

Working in biochemistry labs, I learned early how a solid buffer system saves hours of frustration. 3-Cyclohexylaminopropane-1-sulphonic acid, or CAPS for short, stands out as one of these reliable buffers. It helps keep the pH right where scientists want it, especially for experiments dealing with proteins or enzymes. Any small slip in acidity, and results get tossed aside. Here, CAPS’s stability really matters. Most common in the range of pH 9.7 to 11.1, it outperforms plenty of older buffers that break down or lose strength under heat or sunlight. People in protein chemistry recognize the value of this steadiness. Growing up, whenever I shadowed senior researchers, they'd pick CAPS over other options for high-alcaline reactions, not just because it works but because it keeps experiments from needing to be repeated. That kind of dependability keeps projects and grants on schedule.

CAPS goes beyond the typical uses. In protein purification and electrophoresis, its importance jumps. Anyone who’s handled gels knows that a buffer crashing during a run means ruined samples and wasted money. CAPS’s strong buffering at high pH keeps these proteins safe while they separate. Manufacturers often recommend it for blotting procedures too, especially western blots, since it helps antibodies bind to their targets more effectively. This isn’t minor: Skipping the right buffer means getting fuzzy images and missing the bands researchers spent weeks trying to reveal. It’s easy to forget the hours lost to troubleshooting when a simple switch to CAPS could have cleared things up.

Routine isn’t always exciting, but labs depend on tools that don’t mess up the workflow. In HPLC and other chromatographic techniques, the background noise in buffers can ruin an expensive analysis. CAPS boasts low UV absorbance, making it one of the best choices for samples that’ll be measured under a spectrophotometer. Back in my student days, I learned this the hard way — a lousy buffer choice forced my group to repeat a project. When someone suggested CAPS, our peaks finally made sense. Decisions like this don’t just save money. They save careers in tight research environments, especially when deadlines loom.

With strong buffers like CAPS, the issue of cost pops up. Labs everywhere feel the strain of tight budgets, so choosing pricier chemicals is never casual. Still, replacing ruined samples or failed experiments costs even more. Labs stuck with poor funding often try to stretch cheaper buffers, but in the end, they lose more time. A smart approach involves open communication among lab teams. Sharing feedback on buffer performance, keeping detailed logs, and pooling resources allows even smaller labs to afford tools like CAPS. It can also help to check for generic suppliers or bulk purchases where quality still meets the grade.

One more thing — safety. CAPS is no more hazardous than many other chemicals in a well-run lab, but its use requires protective gloves, goggles, and careful disposal. Handling powders, I always take care to avoid direct contact or accidental inhalation. Proper training matters, especially for students or anyone new to the bench. Ignoring protocols to save a few minutes often leads to costly mistakes. Trustworthy suppliers provide guidance, which minimizes risks. Expert oversight from lab supervisors in storage and handling makes these chemicals accessible to everyone without raising unnecessary concerns.

3-Cyclohexylaminopropane-1-sulphonic acid is less of a tongue-twister when you break it down. At its core, it’s built from a cyclohexyl group—a ring of six carbon atoms connected like links in a chain—anchored to an amino group, which then stretches out along a propane backbone to a sulfonic acid group at the tail. If you sketch it, that cyclohexane ring offers a chunky, three-dimensional structure, almost like the skeleton of a tiny bike tire. That long tail isn’t just for show. The sulfonic acid gives this molecule a highly polar section, making it dissolve well in water.

If you want the scientific shorthand: the structure goes like this. Take cyclohexylamine (a cyclohexane ring with an amine group). Attach it at the nitrogen atom to a three-carbon chain (propane). Stick a sulfonic acid group—SO3H—right at one end.

A lot of people outside of labs may glance past a compound like this, but deep in biochemical research, each bend and bond matters. Sulfonic acids stand out because of their strong acidity. Unlike weak organic acids, they jump into reactions. The cyclohexyl part brings in a sturdy, bulky presence. This impacts how the molecule fits or avoids certain spaces, especially in complex solutions or reactions.

I remember during my time in a research group, we looked at compounds like this when we wanted buffers that wouldn’t interfere with proteins or enzymes. For anyone who's worked in a biochemistry lab, keeping proteins happy while keeping the environment stable isn't just technical—it’s a daily puzzle. The cyclohexyl group resists easy breakdown, so it stays put where you need it, while the propane-sulphonic acid tail interacts smoothly with water and ions.

One thing about compounds with a sulfonic acid is their use as biological buffers. This means researchers grab these kinds of molecules to keep pH from swinging wildly in solutions where even a small change can ruin experiments. A molecule like 3-cyclohexylaminopropane-1-sulphonic acid offers stability and compatibility with a wide array of proteins. Protein crystallization relies on minimal interference, and the structure of this acid delivers just that.

On top of that, the spacing of the nitrogen and acid groups changes how the molecule sits in aqueous solutions. This can blunt unwanted side-reactions, letting labs run longer experiments without constant tweaking. Researchers and pharmaceutical teams appreciate this because small improvements save significant money and time across dozens of experiments.

While this type of buffer works well for many uses, not all labs want to handle sulfonic acids, especially in bulk. If you’ve ever opened a bottle, you know their dust kicks up fast and can sting eyes or skin. It helps to keep robust ventilation and proper gloves within arm’s reach. Teams working with newer protein drugs sometimes run into solubility headaches, prompting chemists to hunt for alternative structures or tweak the tail ends for smoother dissolving.

Possible solutions? Work progresses on salts and derivatives of sulfonic acids that dissolve even faster or bind fewer metal ions. Automation in labs might improve how researchers dose these buffers, cutting waste and increasing accuracy. As the world asks pharmaceutical labs and biotech groups to scale up, improving these everyday reagents could unlock faster medical discoveries for everyone.

3-Cyclohexylaminopropane-1-sulphonic acid pops up in a handful of laboratory settings. Most folks who handle chemicals in the workplace recognize safety data sheets as the first resource for hazard information. You look for clear signals: skull symbols, flammable icons, or exclamation marks. With this acid, those warning signs aren't always obvious, and some might assume that means it's safe. That’s a trap I’ve seen people step into—assuming “not famous” means “not dangerous” can cost you.

Lab safety isn’t just a checklist. During my stint working with organic compounds, every new bottle demanded respect. 3-Cyclohexylaminopropane-1-sulphonic acid has been labeled under irritant categories. Skin or eye contact can leave a person in some serious discomfort. This isn’t a guess—actual case reports show redness, swelling, and persistent irritation in exposed users, sometimes even when gloves and goggles are on. Inhalation also carries risk, especially in powder or aerosol form. NIOSH and OSHA scrutinize similar amine-based compounds for good reason, considering the lungs don’t appreciate surprises.

Tracking the toxicity of niche chemicals gets tricky. Publicly reviewed toxicology data for 3-Cyclohexylaminopropane-1-sulphonic acid remains spotty. Animal tests on amine-sulphonic acids suggest potential for liver and kidney effects if large amounts get into the system. Long-term exposure hasn’t played out publicly, but the structure suggests caution. The cyclohexyl group brings a bulkier profile, which can make it stubborn in the body. That means proper ventilation and routine wipe-downs in the work area aren’t overkill—they’re insurance.

Chemical runoff matters. In my local wastewater plant tours, I witnessed the thrash of cleaning up lab streams. Amines can be tough on water systems, with aquatic organisms sometimes faring worse than humans. European research groups have flagged cyclohexylamines for toxicity to daphnia and fish. Even if this isn’t the most aggressive acid around, careful disposal remains crucial. Waste bins, not the drain, become the better option—especially where the law asks for proof of responsible handling.

Replacing unknowns with safer alternatives should stay on the table. If you’re running a chemistry outfit, dig deep into the actual need for this compound versus something with clearer hazard lines. Substitutions help, even if suppliers push a certain reagent. For those who use it anyway, PPE isn’t negotiable—think thick nitrile gloves, splash guards, and real fume extractors, not just desk fans. Training matters, too. Every new staffer should see what mistakes look like, not just what the manual says.

Manufacturers should invest in better hazard communication and publish test results. You don’t protect people with silence or jargon. Publicly available databases like PubChem and ECHA thrive on updated dossiers, and labs should send reports upstream, too. Staying in touch with environmental agencies helps communities spot trouble before it starts. Risk doesn’t disappear just because a name isn’t on a watchlist.

3-Cyclohexylaminopropane-1-sulphonic acid shows up in specialized labs, often playing a role in various buffer systems. Its nature as a sulfonic acid means it attracts water from the air. Anybody who works with similar compounds knows moisture and exposure can lead to clumping or chemical shifts. This isn't just a quality issue; chemical changes can ruin test results and make researchers start over.

Ignoring the needs of compounds like this often brings trouble. Excess heat, sunlight, or humidity can make the acid decompose, leading to unreliable research data or expensive restocking. In my own experience, staff sometimes stash lab chemicals on shelves without checking for climate control, thinking short-term storage won’t matter. Then the powder clumps up, or the batch loses its expected reactivity. Each time that happens, every downstream process takes a hit.

Safety should never be just a checklist. Storage mistakes with chemicals can cause anything from lab accidents to failed experiments. According to Merck Safety Data Sheets, this sulfonic acid doesn’t carry acute hazard warnings but will cause skin or eye irritation if mishandled, and its lack of volatility doesn’t mean it’s harmless.

Leaving a vial open on the benchtop or stacking it near volatile solvents once caused a friend’s sensitive pH study to go sideways. The sample’s behavior shifted over days, and it took weeks to trace the source—storage conditions had wrecked the material’s integrity. Situations like this explain why disciplined storage isn’t a mere formality.

Rushed routines undermine solid lab work. Labs should invest in climate-logged storage, even for “inert” chemicals. Auditing storage areas twice a year can expose creeping problems before they get out of hand. Leaning on research from sources like Sigma-Aldrich and reading Safety Data Sheets for every product pays off, both for personal safety and research integrity.

At the end of the day, chemical storage isn’t about bureaucracy. Every bottle tells a story, and the careful steps taken today set up good results tomorrow.

Walking through a chemical supplier’s catalog or scrolling on their site, you see all kinds of numbers and letters tacked onto names like “3-Cyclohexylaminopropane-1-sulphonic acid.” Academic institutions might get it as, say, a 98% pure standard, listed as “analytical grade.” Research outfits, bioscience companies, and manufacturers all check for these tags before they buy. In the world of applied chemistry, wrong purity or grade can turn a routine run into a costly mistake. I’ve worked on both sides: hunting for standards that shape research outcomes, and sifting through documentation to verify the bottle matches its label.

Most chemical companies flag this acid with purities ranging between 95% and just above 99%. The higher end usually comes as “analytical grade” or “ACS grade.” Academic researchers and diagnostic lab techs stick with 98% or better because impurities—especially certain trace metals—can ruin sensitive results. I once watched a week’s worth of enzyme kinetic studies fall apart due to unknown contaminants traced back to an off-grade buffer. Standards like the ACS (American Chemical Society) or the ISO have detailed purity specs to cut down on risks like that.

If your work leans toward pH control in proteins or cell culture development, any impurity in this acid could alter biological pathways. Grabbing a jar labeled “technical grade,” which usually falls below 95%, asks for trouble in clinical or pharmaceutical development. Trace levels of impurities don’t just affect color or solubility; they upset data and botch product safety reviews. Long ago, our team ordered the cheaper option for pilot work, trusting spec sheets and bulk pricing. Later, we learned that minute concentrations of heavy metals in the lower-grade batch triggered erratic readings in our assays. Our reputation rode on repeatability and clean runs, and that batch put it all at risk.

Labs and manufacturers share the same anxiety: no one wants a recall. Teams working at scale—like batch reactors making APIs (active pharmaceutical ingredients)—demand certification sheets, batch numbers, and sometimes require on-site audits of suppliers. Any supplier short on transparency raises a red flag. Documentation needs to detail not just overall purity by titration or chromatography but also spell out heavy metal, moisture, and organic contaminant levels. It’s the difference between hitting compliance and triggering a regulatory storm.

To keep experiments trustworthy, always press for supplier data sheets. Good vendors break down content by percentage, listing things like sulfate, chloride, and even water content. Some niche suppliers focus on “ultrapure” lines pitched at biotechnology and diagnostic kits. Price climbs, but you skip cleanup headaches. In my experience, risk never pays—time lost to investigating inconsistencies or re-running tests turns out far more expensive than buying the right grade up front.

Auditing quality at the source brings peace of mind in high-stakes fields. Industry bodies like ACS post certification requirements, and reputable chemical firms keep internal quality systems up-to-date. Those layers of accountability show up in every bottle’s batch certificate. Bottom line: purity and grade aren’t checkboxes for paperwork—they shape scientific accuracy, project deadlines, and the safety of everyone down the line.

| Names | |

| Preferred IUPAC name | 3-(Cyclohexylamino)propane-1-sulfonic acid |

| Other names |

CAPS N-cyclohexyl-3-aminopropanesulfonic acid Cyclohexylaminopropanesulfonic acid |

| Pronunciation | /ˈθriː saɪ.kloʊˈhɛk.sɪlˌæm.ɪ.noʊˈproʊ.peɪn wʌn ˈsʌl.fɒn.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 68189-09-1 |

| 3D model (JSmol) | `3d:JNBRITXZODSMBU-UHFFFAOYSA-N` |

| Beilstein Reference | 1690422 |

| ChEBI | CHEBI:90849 |

| ChEMBL | CHEMBL196622 |

| ChemSpider | 177457 |

| DrugBank | DB03713 |

| ECHA InfoCard | 03e6ba85-1cb5-4ad7-bab2-e0aeb7bb7d78 |

| EC Number | 292-722-1 |

| Gmelin Reference | 89853 |

| KEGG | C07049 |

| MeSH | D018490 |

| PubChem CID | 21634412 |

| RTECS number | TC0175000 |

| UNII | LYG6O5V4T3 |

| UN number | UN2811 |

| Properties | |

| Chemical formula | C9H19NO3S |

| Molar mass | 273.40 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 1.18 g/cm³ |

| Solubility in water | soluble |

| log P | 0.00 |

| Vapor pressure | 6.91E-07 mmHg at 25°C |

| Acidity (pKa) | 9.7 |

| Basicity (pKb) | 9.7 |

| Magnetic susceptibility (χ) | -73.07·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.558 |

| Viscosity | 500 to 700 cP (25°C) |

| Dipole moment | 2.85 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 231.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -478.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1155.7 kJ/mol |

| Pharmacology | |

| ATC code | V03AB33 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P264, P271, P272, P280, P302+P352, P321, P332+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Flash point | > 188.5 °C |

| Lethal dose or concentration | LD50 oral rat 5200 mg/kg |

| LD50 (median dose) | LD50 (median dose): >2000 mg/kg (rat, oral) |

| NIOSH | SY8570000 |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Taurine Homotaurine Aminomethanesulfonic acid 3-Aminopropanesulfonic acid |